01

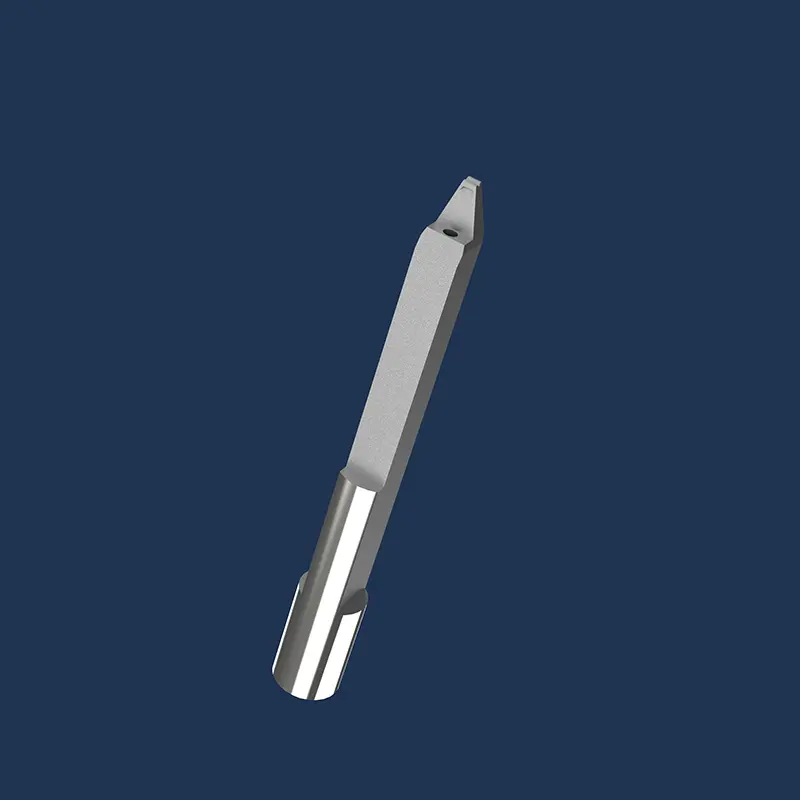

Wedge Bonding Tools

Features

Customizability: Our wedge bonding tools offer extensive customization options to accommodate specific bonding requirements. This includes adapting to various wire diameters, bond angles, and geometries, tailored to meet the diverse needs of semiconductor and electronics manufacturers. By providing these customization features, we ensure that our tools can be precisely aligned with the unique specifications of each application, enabling more accurate and efficient bonding processes. This flexibility allows manufacturers to achieve optimal performance and quality in their wire bonding operations, enhancing the overall effectiveness of their production systems.

Pre-shipment Cleaning and Inspection: Before being packaged and sent to customers, our wedge bonding tools undergo a rigorous pre-shipment cleaning and inspection process. This comprehensive cleaning procedure is designed to eliminate any manufacturing residues, contaminants, or debris that may be present. We adhere to strict cleaning protocols, employing appropriate cleaning agents and equipment to ensure that each tool is entirely clean. Additionally, our inspection process is thorough, involving detailed checks at every stage to confirm that each tool meets our high standards of cleanliness and functionality. This meticulous attention to detail ensures that our customers receive tools that are ready for immediate use, without any issues that could impact performance.

Compatibility and Integration: Our wedge bonding tools are engineered for seamless integration with a wide range of wedge bonder models, including manual, semi-automatic, and automatic systems. They are compatible with industry-standard models from renowned manufacturers such as K&S, Hesse, Delvotek, ASM, Palomar, and others. This ensures that our tools can be easily incorporated into existing systems, enhancing manufacturing efficiency and flexibility. By maintaining compatibility with various equipment and processes, our wedge bonding tools support a smooth workflow and contribute to the overall productivity of your operations. This integration capability helps streamline the bonding process and adapt to different production requirements, making our tools a valuable addition to any wire bonding setup.

Details

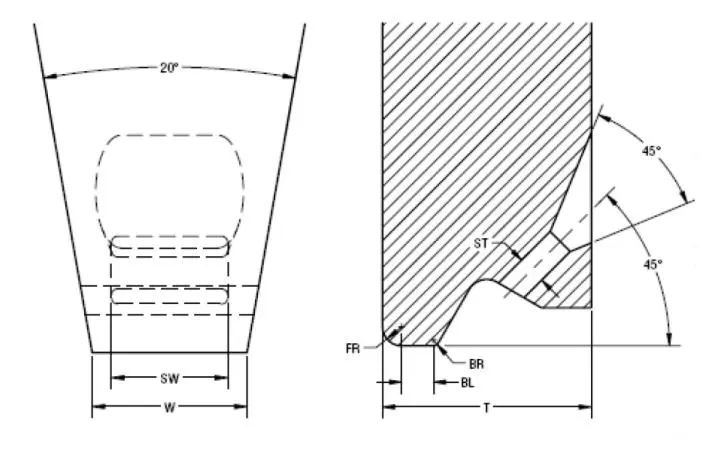

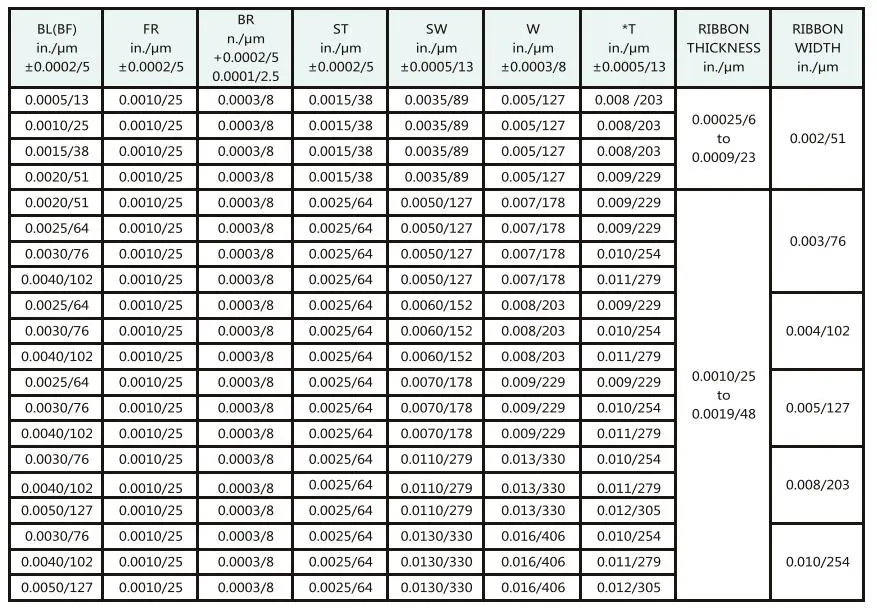

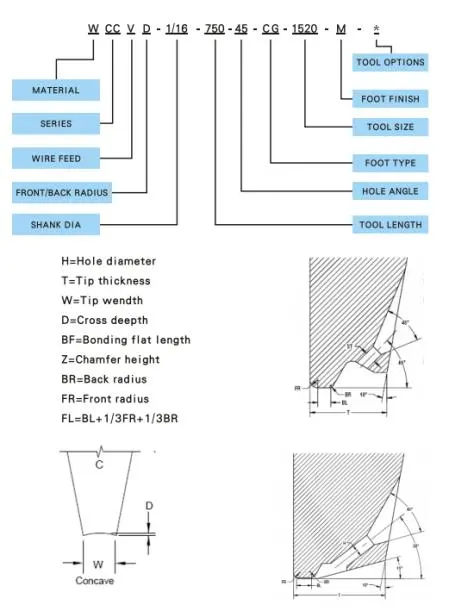

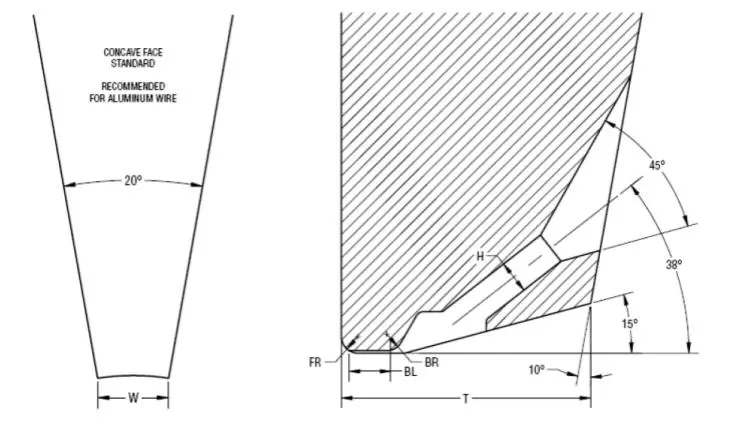

Symbol Explanation

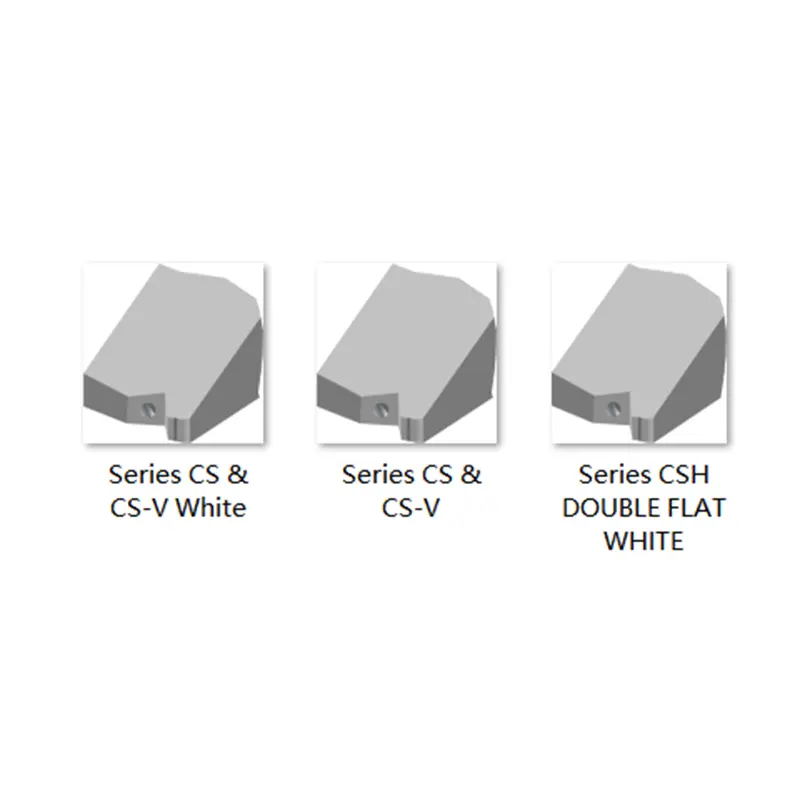

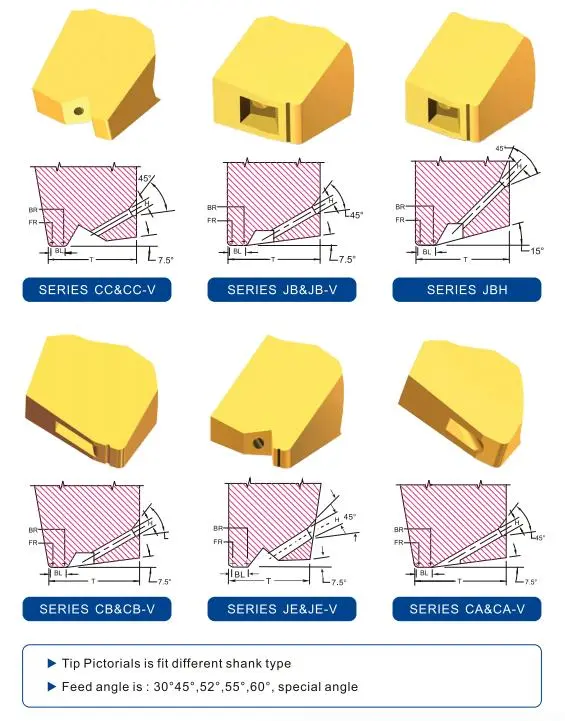

Tip Pictorials 1

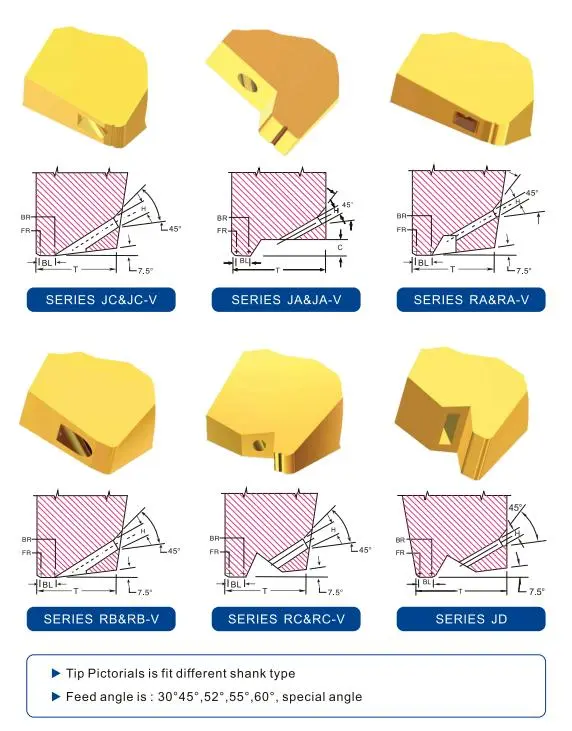

Tip Pictorials 2

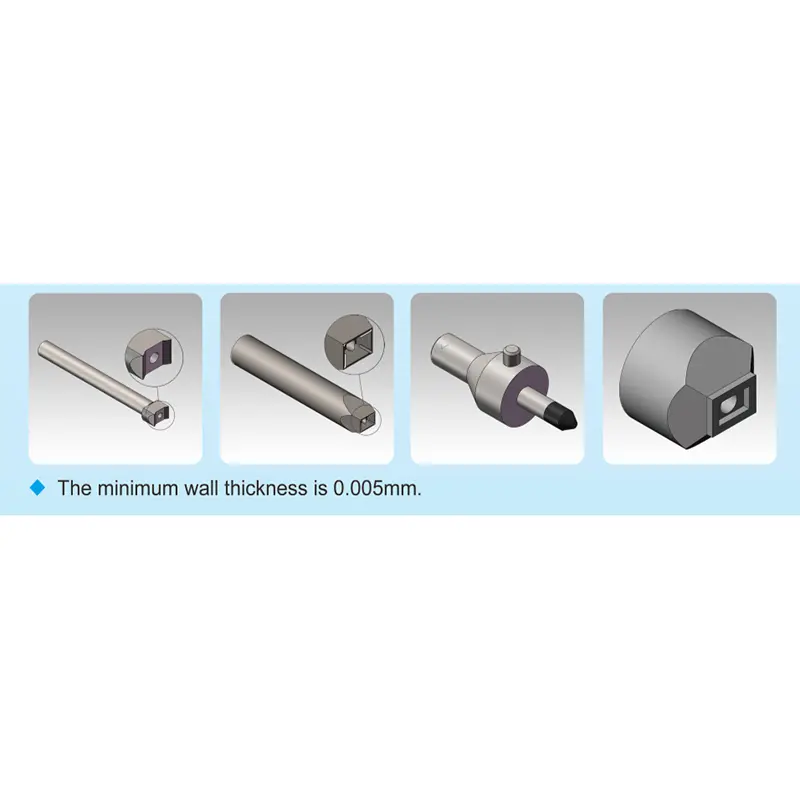

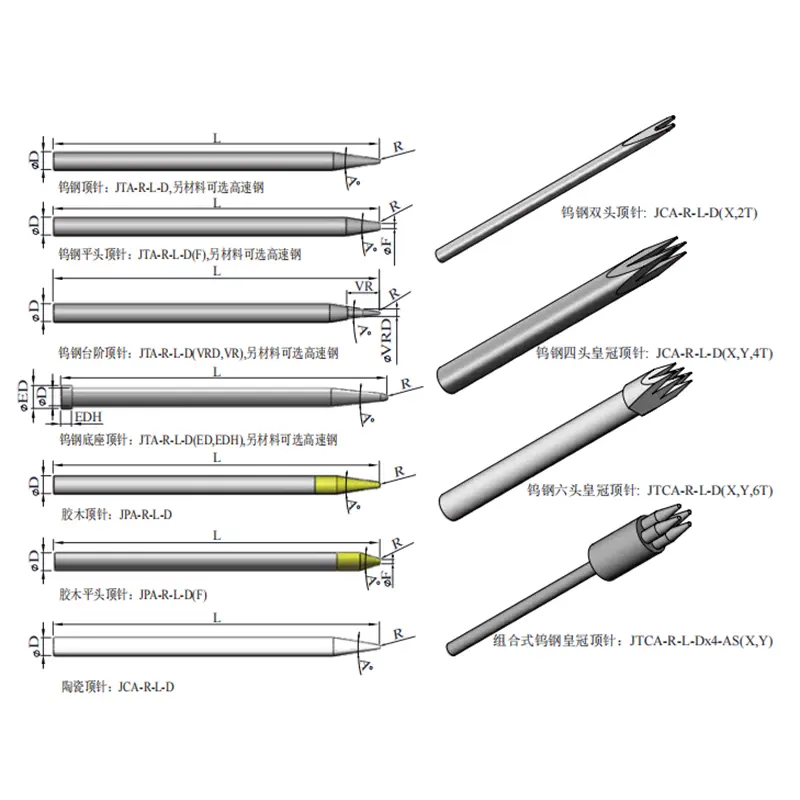

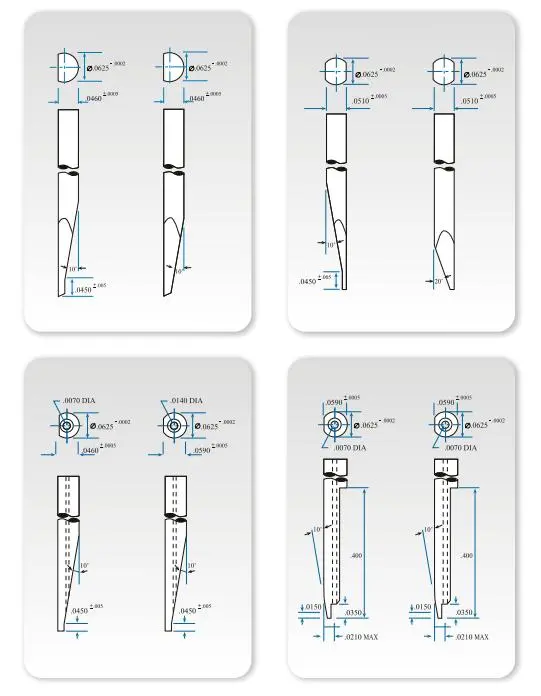

Shank Type

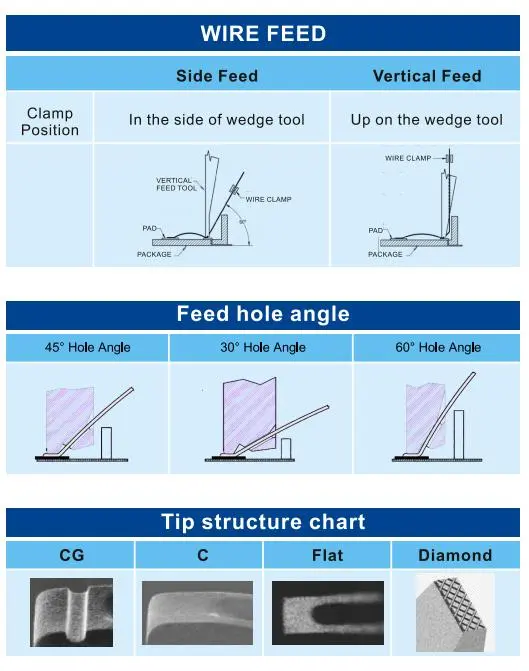

Other Parameters

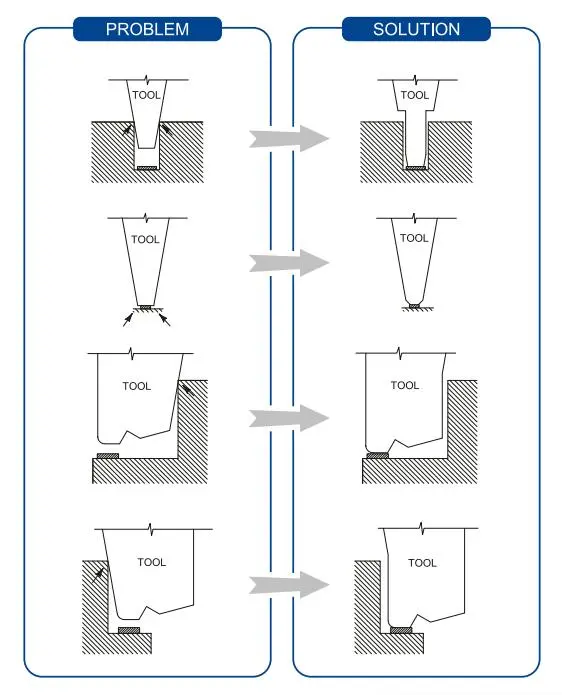

Problems and Solutions 1

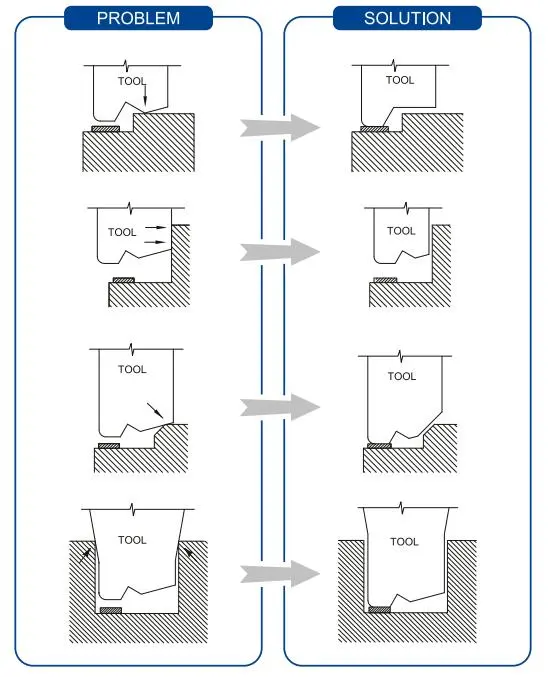

Problems and Solutions 2

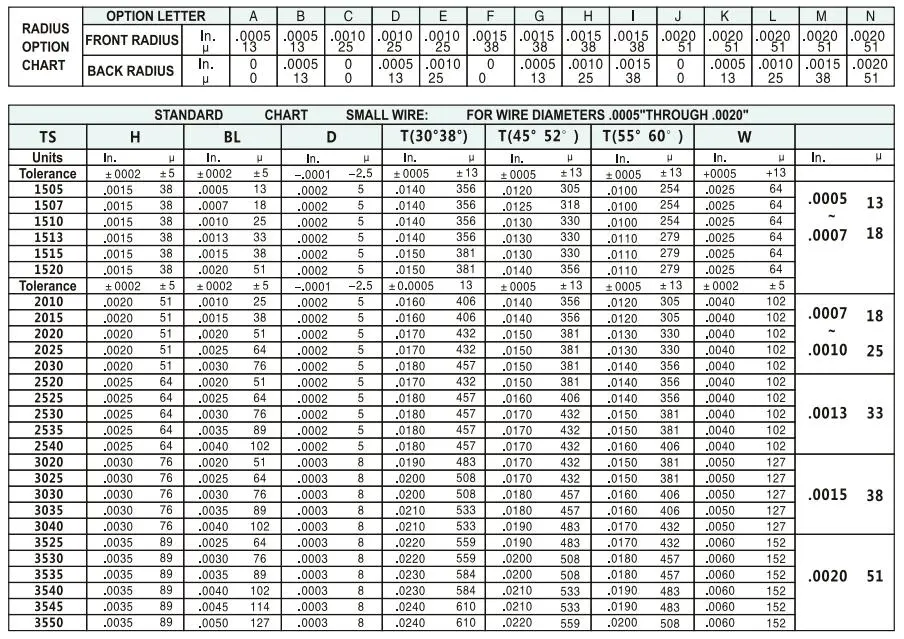

Series JBH

Series JD