Overview of the Wire Bonding Process

Part One: Key Components

-

Wire Material:

The primary material used for bonding is typically gold, chosen for its excellent conductivity, corrosion resistance, and ease of bonding. -

Bond Pad:

This refers to the specific area on the chip or package surface where the wire connects. -

Bonding Machine:

A specialized device that utilizes ultrasonic energy, heat, and pressure to create the bond.

Part Two: Typical Steps

-

Wire Feeding:

The wire is drawn from a spool through a capillary tube. -

Ball Bonding:

Ultrasonic energy and heat are applied to cut the wire and form a ball at one end. -

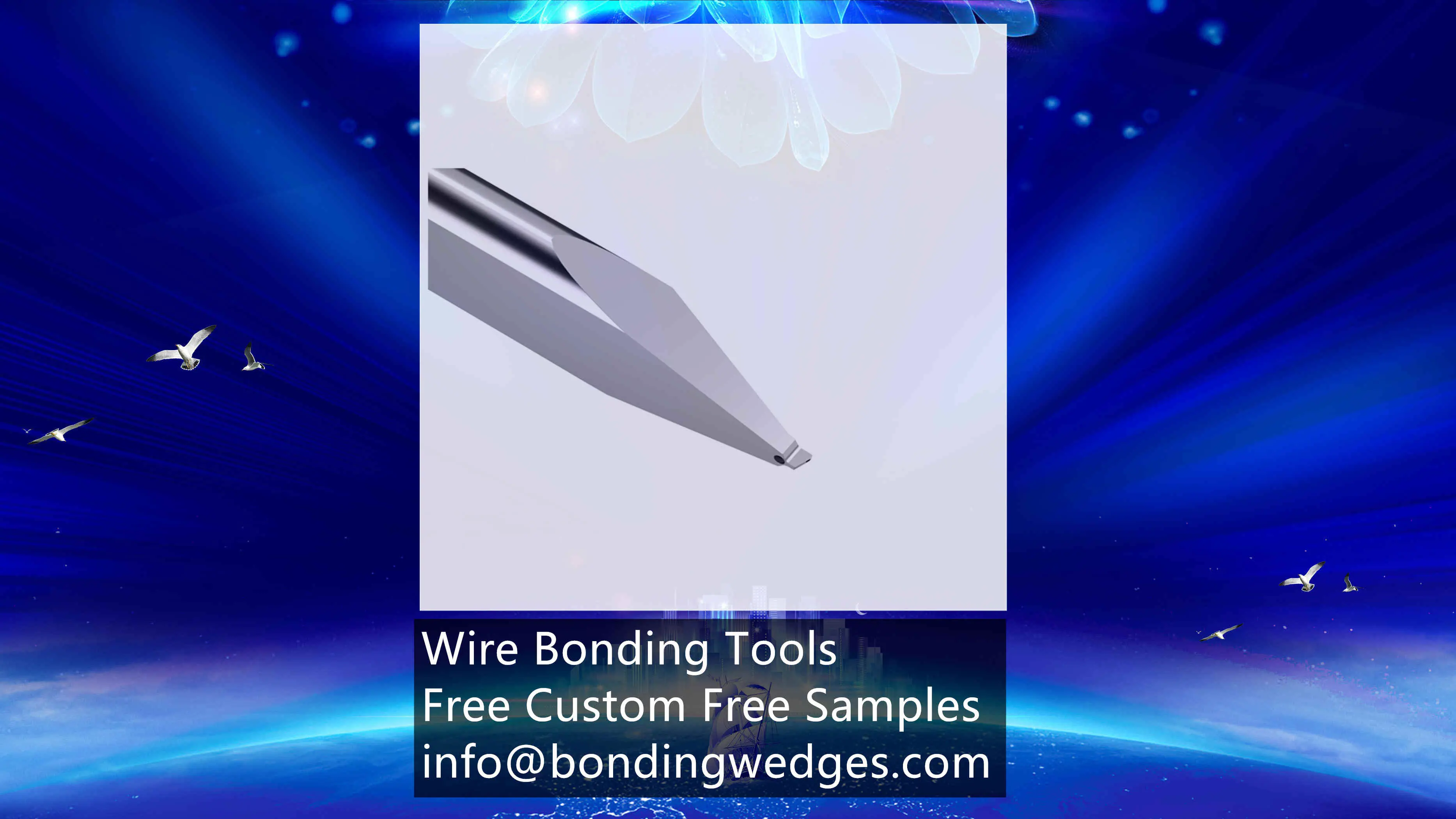

Wedge Bonding:

A wedge tool flattens the other end of the wire and bonds it to the package bond pad.

Part Three: Types of Wire Bonding

-

Ball Bonding:

This is the most common method, where a ball is formed at one end of the wire and then bonded to the pad. -

Wedge Bonding:

Primarily used for power devices, this method flattens one end of the wire and bonds it to the pad. -

Stitch Bonding:

A combination of ball and wedge bonding, used for specific applications.

Part Four: Influencing Factors

-

Wire Material:

The choice of wire material significantly impacts its conductivity, mechanical strength, and bondability. -

Bonding Parameters:

The ultrasonic energy, heat, and pressure applied during the bonding process can greatly affect bond quality. -

Package Design:

The design of the package, including pad layout and surface finish, plays a crucial role in the bonding process.

Part Five: Applications

Wire bonding is utilized in a wide range of electronic devices, including:

- Integrated Circuits (ICs)

- Microprocessors

- Memory Chips

- Power Devices

- Sensors

- Optoelectronic Devices

Part Six: Future Trends

As electronic devices become increasingly complex and performance demands rise, new wire bonding technologies and materials are being developed. Some notable trends include:

-

Advanced Bonding Materials:

Research is underway to explore alternative materials such as copper or silver to enhance conductivity and cost-effectiveness. -

Fine Pitch Bonding:

Techniques are being developed to bond wires to pads with smaller pitches, accommodating higher-density ICs. -

Laser Bonding:

Investigations into laser-based bonding methods aim to improve precision and reliability. -

Hybrid Bonding:

Combining wire bonding with other interconnection technologies, such as

Contact Us

For any questions regarding our products or solutions, kindly entrust them to us and we will respond within 24 hours.

KeyWords

Wedge Bonding ToolWedge Tool

Bonding Wedge

Au Wire Bonding

Concave wedge Tool

Wedge Bonding Machines

Wire Bonding ToolsBonding Equipment SuppliersFine Pitch Bonding ToolsWedge BonderWire bonding equipmentSemiconductor bonding toolsPrecision bonding toolsHigh-performance wire bonding toolsSemiconductor industry toolsBonding tool manufacturerCustomizable wire bonding solutionsQuality wedge bonding equipment