IGBT module packaging: bonding and packaging, what's new?

Lower Switching Losses: Advances in materials and design have led to IGBTs with reduced switching losses, improving efficiency in power conversion applications.

Enhanced Thermal Performance: Improved thermal management techniques and materials are being used to enhance the thermal performance of IGBTs, allowing them to operate at higher temperatures and improving reliability.

Integration with SiC and GaN: There is a growing trend to integrate IGBTs with Silicon Carbide (SiC) and Gallium Nitride (GaN) technologies, which can offer better performance in high-frequency and high-temperature applications.

Smart IGBTs: The development of smart IGBTs, which include integrated drivers and protection features, is becoming more common. These devices can simplify circuit design and improve overall system reliability.

Automotive Applications: With the rise of electric vehicles (EVs), IGBTs are increasingly being used in automotive applications, particularly in traction inverters and power electronics for electric drivetrains.

Modular Designs: Modular IGBT designs are being developed for easier scalability and integration into larger systems, particularly in renewable energy applications like wind and solar inverters.

Digital Control: The integration of digital control techniques with IGBT technology is enhancing performance and enabling more sophisticated control strategies in power electronics.

For the most current advancements and trends in IGBT technology, I recommend checking the latest publications, industry news, and technical papers from reputable sources in the field of power electronics.

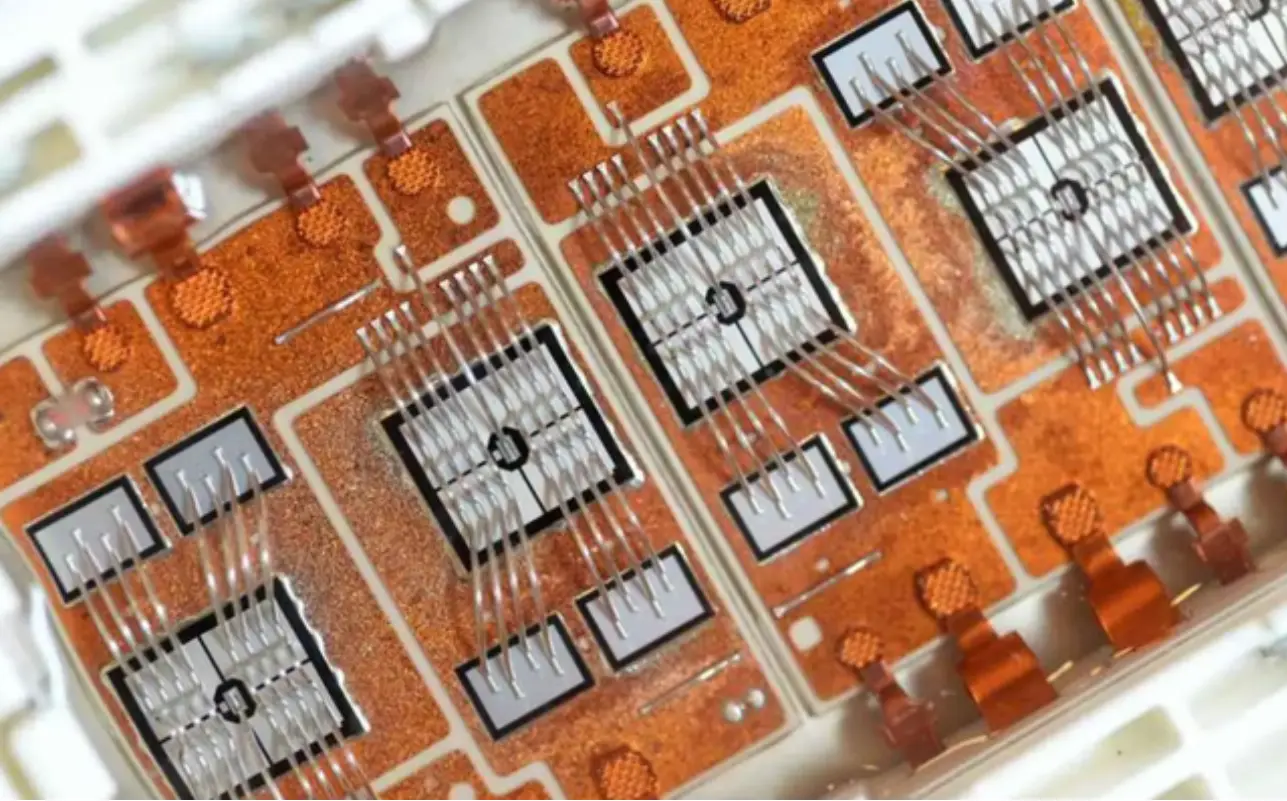

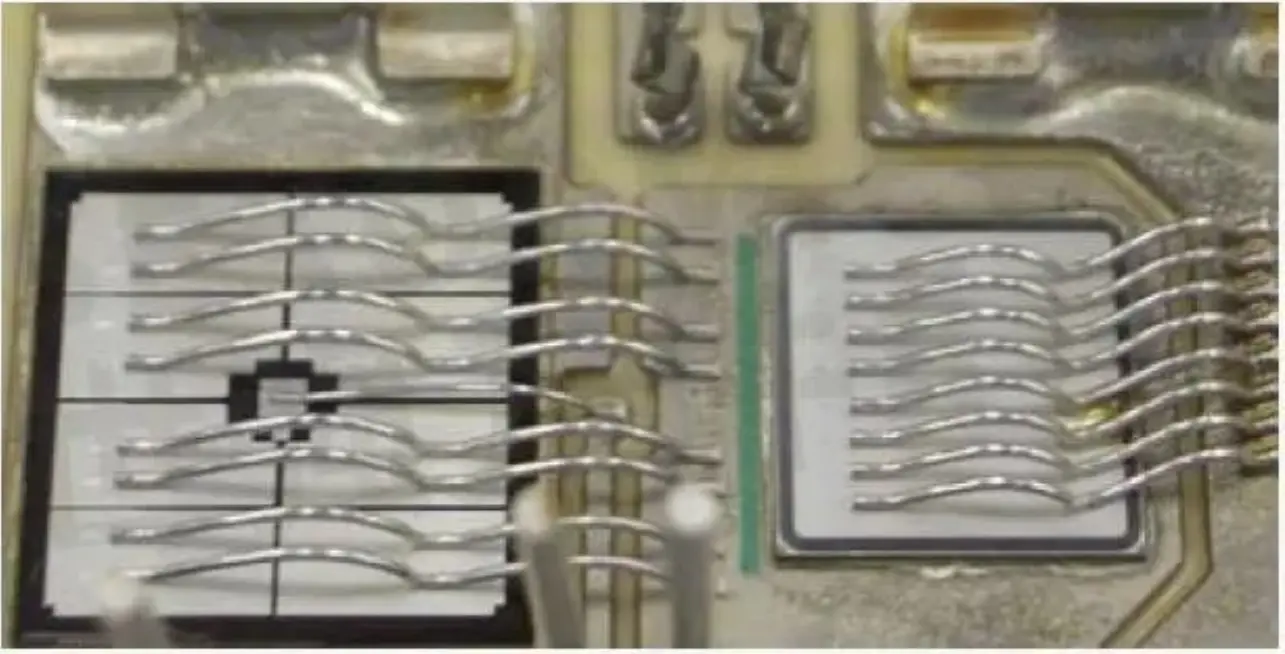

Wire bonding is a technique used to connect small electrodes on a chip to an external circuit. Its purpose is to connect the chip electrodes to the DBC (Direct Bonded Copper) substrate using metal wires, forming internal electrical connections within the module. In IGBT modules, the quality of wire bonding directly affects the electrical performance and reliability of the module. During wire bonding, it is required that the wire diameter is appropriate, the lengths are equal, the bonding points are securely connected, and the distribution is uniform to meet the current-carrying requirements.

From the perspective of bonding principles, there are three types: thermocompression bonding, ultrasonic bonding, and thermosonic bonding.

Thermocompression bonding involves the wire being deformed under the pressure of a heated bonding tool (>250ºC). Bonding is achieved by controlling the time, temperature, and pressure.

Ultrasonic bonding occurs at room temperature, where pressure and ultrasonic frequency elastic vibrations are applied to the bonding surface. This process breaks the oxide layer between the bonded materials, allowing the two solid metals to bond securely.

Thermosonic bonding is a combination of thermocompression and ultrasonic bonding, which can reduce the heating temperature and increase bonding strength, thereby enhancing the reliability of the device. It is the most widely used method.

In terms of bonding processes, there are two types: ball bonding and wedge bonding. In ball bonding, a bonding point is created by melting the bonding wire using a high-voltage electric arc discharge, forming a ball shape under surface tension. This ball is then pressed onto the chip’s electrode, and the bent gold wire is pulled from one bonding point and pressed onto the corresponding position to form a second bonding point. Wedge bonding, on the other hand, involves pressing two wedge-shaped bonding points together to form a connection, without the need for ball formation.

Copper wire or aluminum wire?

In the semiconductor packaging field, metal leads serve as a bridge connecting the chip to the external circuit, directly affecting the chip’s performance. Therefore, the quality of wire bonding is crucial. Parameters such as the material of the wire, diameter, bonding pressure, bonding time, and bonding temperature can all impact bonding quality. For example, if the wire diameter is too large, it can increase parasitic inductance, affecting the module’s high-frequency performance; conversely, if the diameter is too small, it can lead to insufficient bonding strength, reducing the module’s reliability. Thus, optimizing these process parameters is key to improving wire bonding quality.

Aluminum wire bonding is currently the most widely used chip interconnection technology in the industry. The aluminum wire bonding process is highly mature and cost-effective. Aluminum wire is categorized into fine aluminum wire and coarse aluminum wire based on diameter: aluminum wire with a diameter less than 100 µm is referred to as fine aluminum wire, while aluminum wire with a diameter greater than 100 µm and less than 500 µm is referred to as coarse aluminum wire.

Copper wire has a lower resistivity than aluminum wire, providing better electrical conductivity, and its thermal conductivity is higher than that of aluminum wire, resulting in better heat dissipation. Copper wire bonding can enhance the reliability of the bonding process, especially for power modules with high power density and efficient heat dissipation, as it can effectively improve their power cycling capability. In silicon carbide power modules for new energy vehicles, ultrasonic copper wire bonding machines have a broader range of applications. However, copper is harder than aluminum, which requires higher ultrasonic energy and pressure during bonding, potentially leading to mechanical damage to the substrate and issues like cold solder joints.

Considering the advantages and disadvantages of aluminum and copper wires, researchers have developed a new type of bonding wire that wraps a layer of aluminum approximately 25 to 35 μm thick around the copper wire. Since the surface is made of aluminum, there is no need for prior chemical plating treatment of the chip surface during bonding, which improves system reliability. The electrical and thermal conductivity of aluminum-clad copper wire is better than that of aluminum wire, increasing the reliability of the bonding leads and extending the lifespan of IGBT power modules.

Chengdu Ju Xin Li Technology Co.,Ltd. specialize microelectronic assembly tools and materials, including wire bonding tools, die bonding tools, bonding wires, wire bonders etc. Please feel free to contact: https://www.juxinlitech.com/

Contact Us

For any questions regarding our products or solutions, kindly entrust them to us and we will respond within 24 hours.

KeyWords

Wedge Bonding ToolWedge Tool

Bonding Wedge

Au Wire Bonding

Concave wedge Tool

Wedge Bonding Machines

Wire Bonding ToolsBonding Equipment SuppliersFine Pitch Bonding ToolsWedge BonderWire bonding equipmentSemiconductor bonding toolsPrecision bonding toolsHigh-performance wire bonding toolsSemiconductor industry toolsBonding tool manufacturerCustomizable wire bonding solutionsQuality wedge bonding equipment