In the realm of electronic manufacturing, the Tpt Wire Bonder plays a crucial role. This specialized device is essential for connecting tiny wires to semiconductor chips. It ensures reliable electrical connections for various applications. As technology advances, the need for precise and efficient bonding methods increases.

The Tpt Wire Bonder operates by using heat and pressure. It carefully places fine wires onto contact pads, creating strong bonds. However, this process isn’t without challenges. Operators must maintain high levels of precision, or defects can occur. Every misstep can lead to serious issues in device performance.

It's fascinating yet complex. The Tpt Wire Bonder is a perfect blend of science and artistry. Mastering its operation requires skill and practice. Many factors contribute to successful bonding: wire types, temperatures, and materials. Each detail matters. It's a field where ongoing improvement is key.

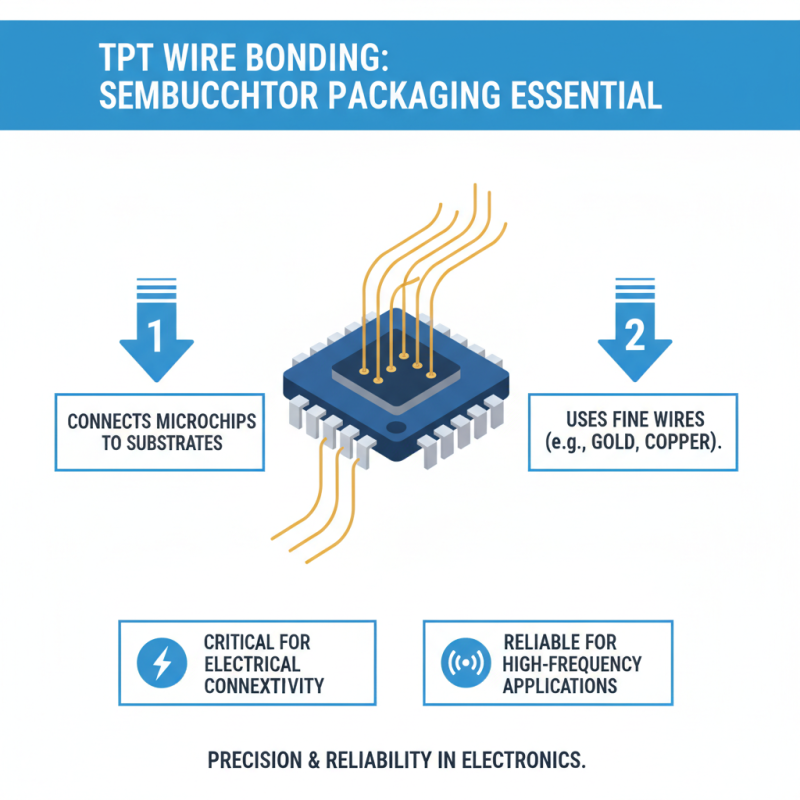

TPT wire bonder is an essential tool in semiconductor packaging. It utilizes fine wires to connect microchips to substrates. This bonding process is critical for electrical connectivity in various electronic devices. High frequency applications often rely on TPT wire bonding due to its precision.

According to industry reports, the global wire bonding equipment market was valued at approximately $2.1 billion in 2022. It is expected to grow steadily. This growth is driven by increasing demand for miniaturized electronics. Moreover, the rise of automotive and consumer electronics fuels this trend. However, challenges persist. The balance between speed and quality poses a significant dilemma for manufacturers.

The TPT wire bonder employs ultrasonic energy to create welds. These connections must be robust yet delicate. Faulty bonds can lead to device failures, which is a critical issue in high-reliability markets. Interestingly, the average failure rate can be around 2-5% for poorly executed bonds. The focus on precision means manufacturers need to constantly improve their processes. In a rapidly evolving industry, reflection on past mistakes becomes essential for future enhancements.

The Tpt wire bonder is an essential machine in the semiconductor industry. It plays a crucial role in connecting the tiny wires from the chips to the circuit boards. A few key components make this work efficient. These include bond heads, ultrasonic generators, and precision positioning systems.

The bond head operates at high speeds. It ensures accurate placement of wires onto surfaces. Ultrasonic generators provide the necessary energy to create strong bonds. The precision positioning system enhances accuracy during the bonding process. This is vital, as misplaced wires can lead to significant failures in systems.

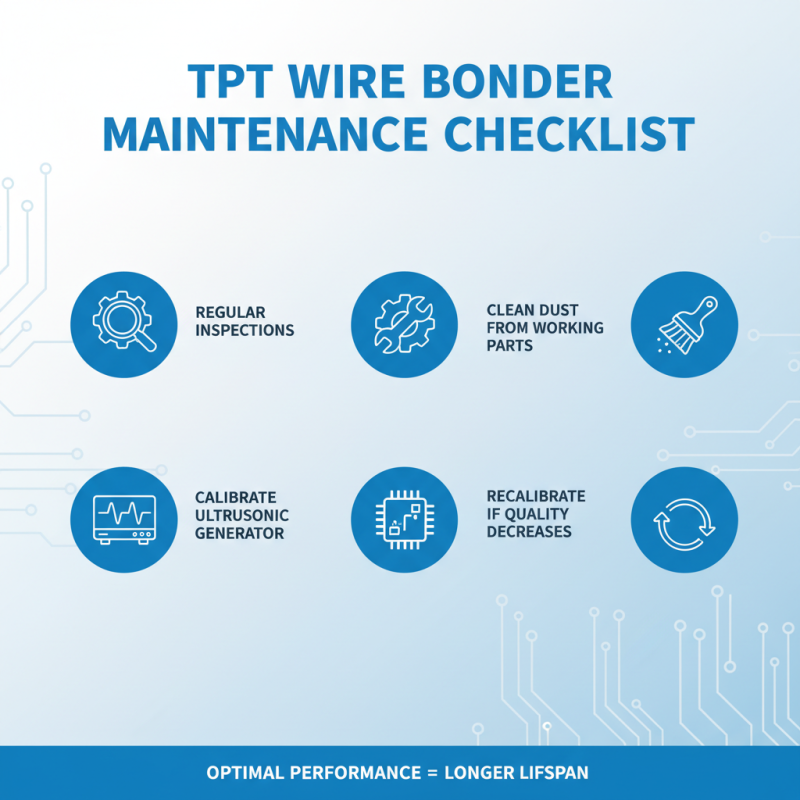

Tip: Always check the calibration of your wire bonder. This helps maintain accuracy and avoid costly errors. Regular maintenance of the ultrasonic generator is also essential. A report from the Semiconductor Industry Association indicates that bonding errors cost manufacturers up to 5% of their total production.

Sometimes, issues arise. Improper material selection can lead to weak bonds. It's crucial to experiment with different wire types to find the best fit. Companies often overlook this step, resulting in performance losses. A study showed that 15% of bond failures come from poor material choices. So, selecting the right materials can save time and money.

TPT wire bonders are crucial in semiconductor packaging. They connect tiny wires between chips and substrates. Understanding how they work helps improve their efficiency.

The working principle revolves around thermosonic bonding. A fine gold or aluminum wire is heated as it's pressed against the surfaces. This creates a bond strong enough to endure stresses. Something often overlooked is the quality of the bonding interface. Any contaminants can weaken the bond significantly.

Operators must monitor various parameters during operation. Temperature, force, and time directly affect bond quality. In practice, even minor fluctuations can lead to defects. Reflecting on this, the need for precise control becomes evident. As technology evolves, enhancing these processes will be essential for reliability.

Tpt Wire Bonder is essential in various industries. Its primary role is connecting semiconductor devices through fine wire bonding. This technique is vital in electronics, ensuring reliability and performance.

In the automotive sector, Tpt Wire Bonder is used to create connections in sensors and chips. These components are crucial for safety and efficiency. Additionally, in the medical field, this technology connects vital components in devices. Precision is paramount, as it impacts patient care. However, achieving consistent quality can be challenging. Small errors in bonding can lead to significant performance issues.

The telecommunications industry also benefits from Tpt Wire Bonder. It plays a vital role in the production of devices that require fast signal processing. But the demand for rapid speed can sometimes sacrifice quality. Balancing speed and precision is a constant challenge. As industries evolve, Tpt Wire Bonder remains a vital tool, yet it requires careful consideration and improvement.

Maintaining a Tpt wire bonder is crucial for optimal performance. Regular inspections help identify issues early. Check for wear and tear on bonding tools. Dust can accumulate in working parts, affecting functionality. Ensure that the ultrasonic generator is properly calibrated. If the bond quality decreases, recalibration might be necessary.

Troubleshooting often involves examining air pressure and temperature settings. An incorrect pressure can lead to weak bonds. Adjusting these parameters can significantly improve results. If problems persist, inspect the wire feed mechanism for blockages. Sometimes, a simple cleaning can resolve the issue.

Operators should document maintenance routines and any problems encountered. This information is valuable for future reference. Recognizing patterns can help in predicting failures. Don't overlook the importance of training. A well-informed operator is essential for effective troubleshooting.