When embarking on DIY projects, the right tools can make all the difference in achieving professional-looking results. One such tool that has gained popularity among DIY enthusiasts is the Epoxy Stamping Tool. This innovative device allows users to create stunning designs and finishes on various surfaces, making it an essential addition to any craft toolbox. Whether you're a novice or a seasoned crafter, understanding the benefits of this tool can elevate your crafting experience and enhance the quality of your projects.

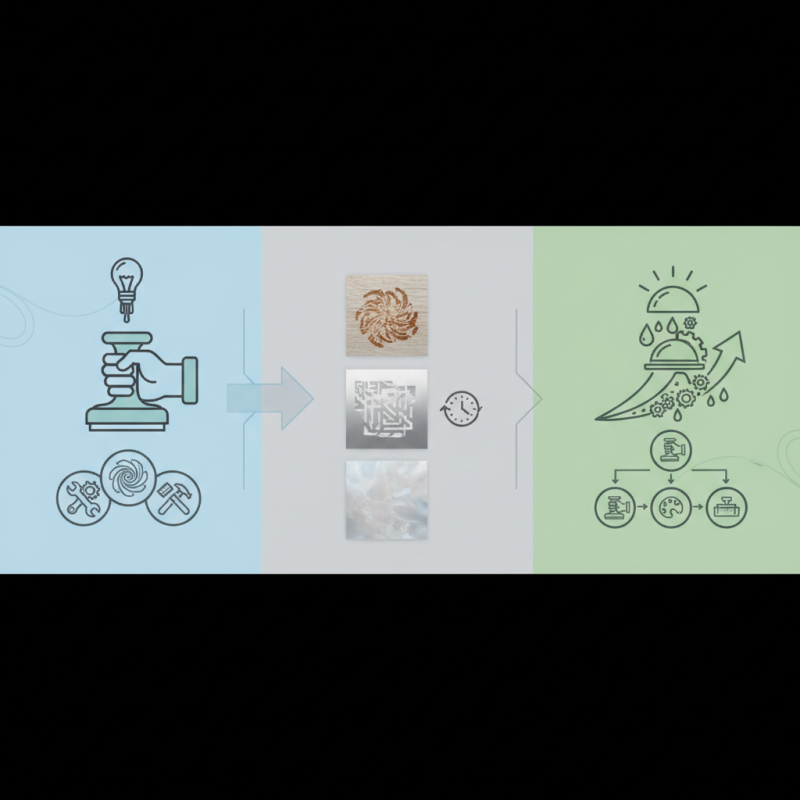

The versatility of the Epoxy Stamping Tool is truly remarkable. It can be used on a variety of materials, including wood, metal, and plastics, enabling crafters to explore different mediums and styles. By applying epoxy with this tool, DIYers can achieve intricate patterns and textures that are otherwise difficult to replicate. Moreover, using an epoxy stamping tool can save time, allowing you to focus on creativity rather than struggling with traditional methods.

In this article, we will delve into the reasons why incorporating an Epoxy Stamping Tool into your DIY repertoire is not just a trend, but a game-changer. From enhancing the aesthetics of your projects to simplifying the crafting process, this tool offers a multitude of benefits that can inspire you to take on new challenges and projects with confidence.

Using an epoxy stamping tool in your DIY projects can enhance both the quality and creativity of your work. One of the primary benefits is the precision it offers. With a stamping tool designed for epoxy, you're able to create intricate designs that are difficult to achieve by hand. This precision leads to a professional-looking finish, elevating your crafts from simple projects to stunning pieces of art. Whether you're working on home decor, personalizing gifts, or making custom furniture, the ability to add detailed patterns and textures sets your work apart.

Another significant advantage is the efficiency gained when using an epoxy stamping tool. Traditional crafting methods often require multiple steps and extensive manual labor, which can be time-consuming. An epoxy stamping tool streamlines the process, allowing you to apply designs quickly and uniformly. This not only saves time but also reduces the likelihood of errors, enabling you to focus more on your creative vision rather than getting bogged down in execution. Embracing this tool can transform how you approach your DIY projects, making them more enjoyable and rewarding.

When it comes to DIY projects, having the right tools can make all the difference, especially when working with epoxy.

Epoxy stamping tools come in various types, each designed to cater to different creative needs. One of the most popular variants is the silicone stamping mat,

which allows for easy and flexible molding of epoxy into intricate designs. These mats can be reusable, making them both cost-effective and user-friendly for crafters of all skill levels.

Another type to consider is the acrylic stamp. Acrylic stamps provide clean and precise impressions, making them ideal for those who are looking to achieve detail in their designs.

They can be easily customized by using different colors and patterns, allowing for a wide range of creative expressions. Additionally, there are metal and wood stamps, which are great for adding texture and depth to your epoxy projects.

Tips: Always ensure your workspace is properly prepared before starting your project. A clean surface will help prevent dust and debris from interfering with the epoxy's finish.

Also, experiment with different stamps and materials to find the perfect combination that suits your style. Don't hesitate to mix and match tools to discover unique designs that stand out!

When it comes to selecting the right epoxy stamping tool for your DIY projects, understanding your specific needs is crucial. Start by evaluating the types of projects you plan to undertake. For intricate designs or large-scale stamping, a tool that offers versatility and adjustable pressure settings will be beneficial. Consider whether you need a lightweight option for easy maneuverability or a more robust tool for heavy-duty projects. Additionally, assess the size of the stamping plates, as larger plates can save time on designs but might be more cumbersome to handle.

Another critical factor is the material of the stamping tool. Tools made from durable materials like stainless steel or high-quality plastic ensure longevity and resilience against wear and tear. If you're a beginner, look for user-friendly models with clear instructions, while advanced users might appreciate tools with more features and settings. Finally, read reviews and seek feedback from fellow DIY enthusiasts to gather insights on performance and ease of use, helping you make a well-informed choice that aligns with your creative aspirations and project requirements.

When embarking on DIY projects, an epoxy stamping tool becomes an invaluable asset for achieving professional-quality results. Using this tool not only enhances the aesthetic appeal of your creations but also increases their durability. According to industry reports, the global epoxy resin market is projected to reach $16.4 billion by 2027, driven by the growing demand for high-performance materials in various applications, including construction, automotive, and arts and crafts. This surge indicates the increasing popularity and necessity of epoxy-related projects and tools in the DIY realm.

To effectively utilize an epoxy stamping tool, start by ensuring your workspace is well-prepared and free of dust and debris. Measure and mix the epoxy resin and hardener as per the manufacturer's guidelines. Once mixed, pour it onto your chosen surface and use the stamping tool to imprint patterns or designs while the resin is still in its liquid state. It's essential to work methodically, as a report from the American Coatings Association suggests that user error accounts for up to 30% of epoxy application failures. Allow your project to cure completely, following the recommended time to ensure a robust finish. Mastering these steps not only promotes successful outcomes but also encourages creativity and experimentation in your DIY projects.

When using epoxy stamping tools for your DIY projects, avoiding common mistakes can significantly enhance your results. One prevalent error is improper surface preparation. Before applying epoxy, ensure that the surface is clean, dry, and free from dust and oils. Any contaminants can prevent the epoxy from properly adhering, leading to peeling or bubbling. Take the time to sand or wipe down the surface to create an ideal base for your project.

Another common mistake is misjudging the mixing ratio of the epoxy components. Failing to follow the manufacturer's guidelines can result in improper curing, which may affect the durability and finish of the stamped design. Always use a precise measuring tool and mix thoroughly to ensure the chemical reaction occurs as intended. Lastly, don't rush the application process; allowing for adequate drying time is crucial. Hasty work can lead to imprecise stamping, ruining the aesthetic of your project. By being mindful of these pitfalls, you can achieve stunning results with your epoxy stamping endeavors.

| Mistake | Description | Solution |

|---|---|---|

| Inadequate Surface Preparation | Failing to clean the surface properly can lead to an improper bond. | Ensure surface is clean, dry, and free of dust or grease before applying epoxy. |

| Incorrect Mixing Ratios | Using wrong ratios can cause poor curing and strength issues. | Always follow the manufacturer's instructions for mixing ratios accurately. |

| Choosing the Wrong Tool | Using an unsuitable tool may affect the finish and application. | Select an epoxy stamping tool specifically designed for your project requirements. |

| Not Working in Ideal Conditions | Humidity and temperature can significantly affect curing. | Monitor environmental conditions and try to work within recommended temperature and humidity ranges. |

| Skipping Safety Gear | Neglecting personal protection can lead to health issues. | Always wear gloves, goggles, and a mask when working with epoxy. |