In the world of semiconductor manufacturing, the Tpt Wire Bonder plays a crucial role. Dr. Emily Chen, an expert in microelectronics, once said, "A well-utilized Tpt Wire Bonder is the key to reliable connections." This statement underscores the importance of mastering this technology.

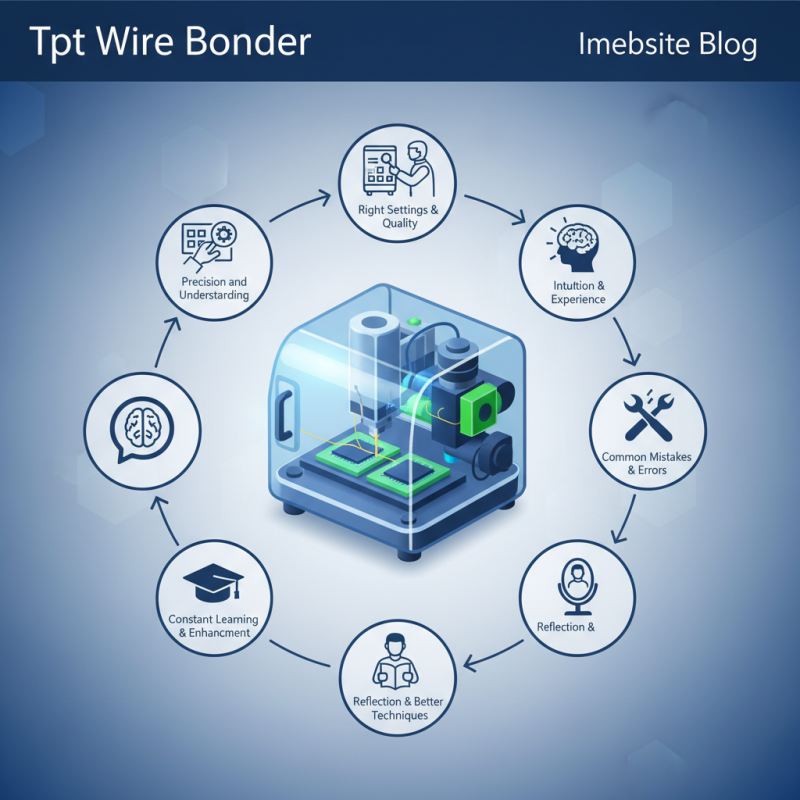

Effectively using a Tpt Wire Bonder requires precision and understanding. Operators must be trained to identify the right settings for bonding quality. Even minor adjustments can lead to significant improvements in performance. It's not just about following protocols; it’s also about honing intuition through experience.

Mistakes can happen during the bonding process. Operators might overlook simple factors like wire tension or alignment. These errors can result in poor connections. Reflection on past experiences often leads to better techniques and practices. Through constant learning, users can enhance their effectiveness with a Tpt Wire Bonder.

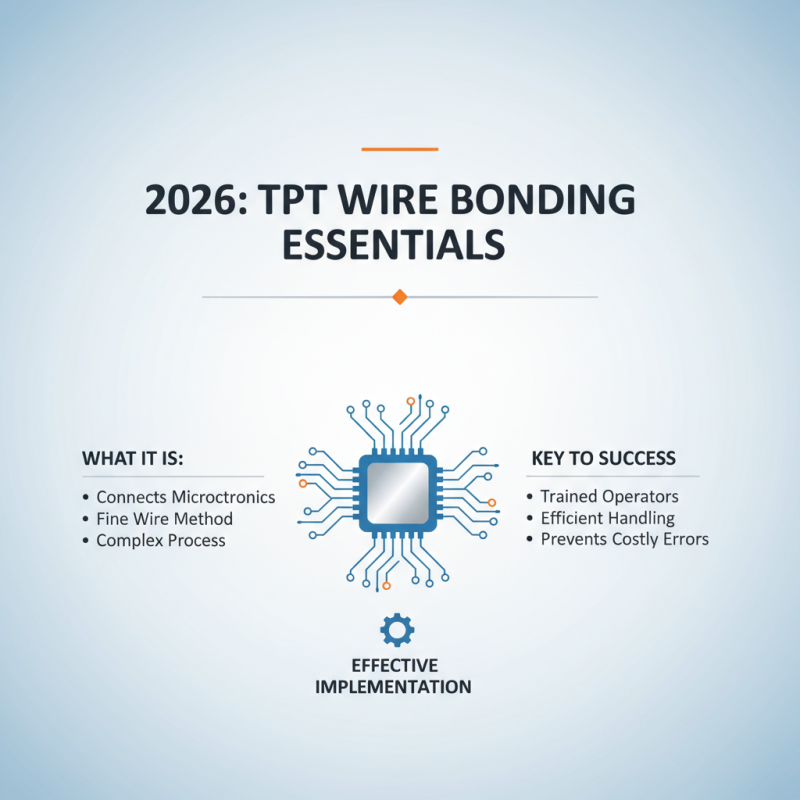

In 2026, understanding TPT wire bonding technology is crucial for effective implementation. This method connects microelectronic components through fine wires. The process is complex and requires focus. Operators must be trained to handle the equipment efficiently. Mistakes can lead to costly errors.

The key to successful TPT wire bonding lies in mastering the basics. Knowledge of materials and environmental conditions is essential. Bonding temperature and pressure must be carefully monitored. Variables like humidity can impact results. Precision is vital in every step. Regular maintenance of the equipment ensures consistent performance.

Challenges are common in this field. Operators may struggle with tool calibration or wire selection. Reflecting on these issues can lead to improvement. Each bonding process is unique. Practitioners should document results to refine techniques. This ongoing learning journey is vital for advancing skills in TPT wire bonding.

Using a TPT wire bonder effectively involves understanding key parameters that influence performance and reliability. Wire bond height is crucial. A consistent bond height ensures strong connections, reducing reliability issues. Inadequate height can lead to weak bonds, risking device failure.

Another important factor is the bond force. This parameter impacts the quality of the bond. Too much force can damage delicate components, while too little can result in poor electrical connections. Monitoring this is essential.

Temperature plays a significant role as well. The right temperature promotes optimal bonding. However, excessive heat may cause material degradation. It's a delicate balance. Many operators overlook settings, assuming standard levels are sufficient. Testing and adjusting parameters based on specific applications is often necessary. There’s always room for improvement in the bonding process. Real-world trials can reveal unexpected outcomes.

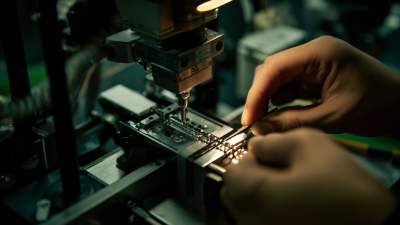

Using a TPT wire bonder effectively requires optimizing settings for better efficiency. Understanding the machine’s capabilities is crucial. Start by examining the wire, the bonding surface, and the environmental conditions. Each factor plays a role in the outcome.

Adjust the force and time settings according to the materials used. A common issue is misalignment, which can result in weak bonds. Experiment with bonding parameters during trials. Take notes on what works and what needs improvement. Make small adjustments. Don’t rush through this process.

Tips: Always keep the workspace clean. Dust can interfere with bonding. Check for machine wear and tear regularly. Small maintenance steps prevent major issues. Experimentation is key, but avoid over-complicating your settings. Simple tweaks can produce significant results. Track your progress methodically. This approach will reveal patterns and highlight areas needing attention.

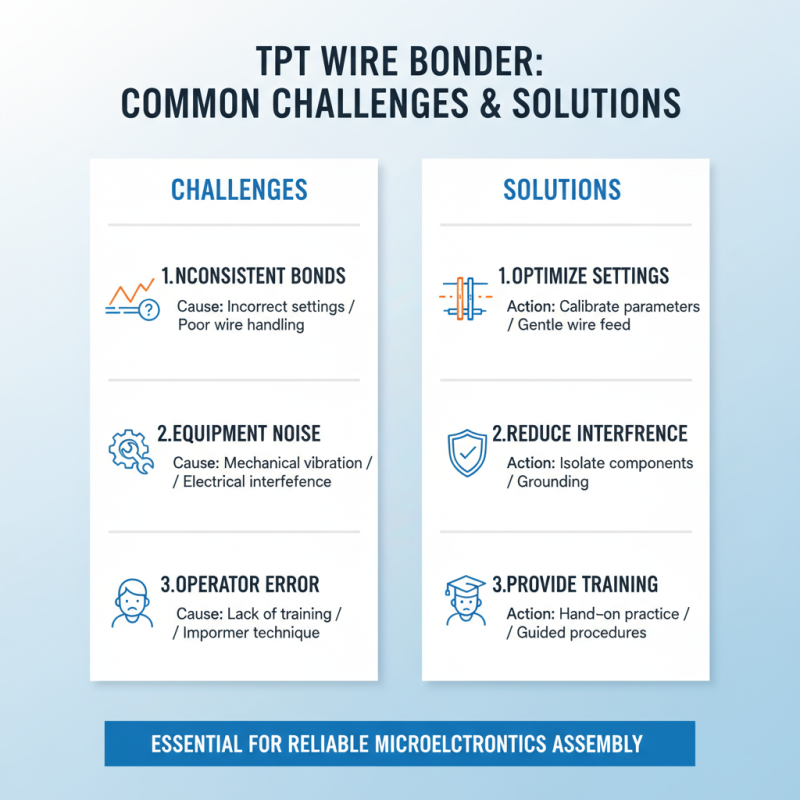

Using a TPT wire bonder can be challenging. Operators often encounter common issues that disrupt their workflow. These issues can be corrected with thoughtful adjustments. Proper training is essential. Many users report inconsistent bonding results. This arises from incorrect settings or improper wire handling. Noise in the equipment can also affect performance.

Another frequent problem is wire breakage during the bonding process. This may happen due to too much tension or incorrect heat settings. Regular maintenance of the tool can alleviate some of these concerns. Operators need to monitor their technique consistently. Differences in materials can lead to unexpected results. It's important to practice and make adjustments as needed.

Misalignment of the wire can be an issue, too. This can result in poor connections and failed bonds. Operators should check alignment frequently. Adjusting the bonding tip can help improve accuracy. Often, users become frustrated and overlook simple fixes. Taking time to reassess the process can lead to better outcomes and efficiency.

Advancements in TPT wire bonding techniques have transformed the semiconductor industry. Market reports indicate that the global wire bonding market is expected to reach $4.5 billion by 2026. This highlights the growing importance of effective bonding techniques in electronics manufacturing.

Recent improvements focus on enhancing bond strength and reliability. For example, innovative materials and methods have been developed. These advancements allow TPT wire bonders to operate at higher temperatures and under more challenging conditions. However, many technicians still struggle to adapt to these new technologies, leading to inconsistent results.

Additionally, automation is becoming a vital asset in wire bonding processes. Studies show that automated systems can increase efficiency by 30%. Despite these gains, not all manufacturers have shifted to full automation. Some continue to rely on manual processes, potentially hindering production speed and quality. The gap between current techniques and future advancements remains an area for reflection and growth in the industry.

| Technique | Advancement | Application | Efficiency Improvement (%) |

|---|---|---|---|

| Ultrasonic Bonding | Enhanced energy transfer | Microelectronics | 20% |

| Thermal Compression Bonding | Lower bond pad damage | Power Devices | 15% |

| Laser Bonding | Increased speed and precision | Automotive Electronics | 30% |

| Pulsed Heat Bonding | Controlled thermal profile | RFID Tags | 25% |

| Flip Chip Bonding | Improved alignment accuracy | High-Performance Computing | 18% |