The Tpt Wire Bonder is a crucial tool in microelectronic assembly. Understanding how to use it effectively is essential for achieving high-quality results. Many users encounter challenges with bonding techniques. Sometimes, even experienced technicians may struggle with the equipment’s settings.

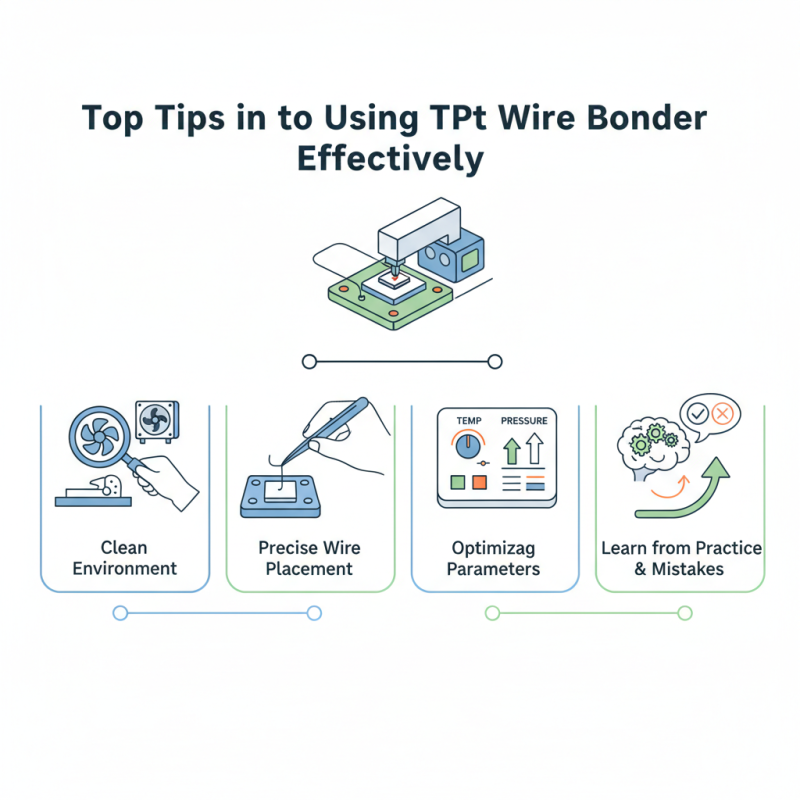

To maximize the benefits of the Tpt Wire Bonder, one must focus on several key practices. For instance, maintaining a clean working environment can greatly enhance performance. The bond quality often hinges on the precision of wire placement. Moreover, adjusting parameters like temperature and pressure can be tricky, yet rewarding.

It's important to learn from mistakes. A misalignment can lead to subpar connections. Continuous practice and reflection on previous projects can foster improvement. By embracing both successes and failures, users can navigate the complexities of the Tpt Wire Bonder more confidently.

Tpt wire bonding technology is essential in electronics. It connects tiny chips to their substrates efficiently. Understanding its basics can significantly improve workflow and outcomes. The process relies on precise heat and pressure to bond gold wires to metal pads. Proper control of these parameters is critical for achieving strong bonds.

One effective tip is to routinely check your equipment calibration. Misalignment can lead to weak bonds. Also, keeping your workspace clean helps prevent contamination, which may weaken bond integrity. Regular maintenance of tools is crucial too.

Experimenting with different bonding parameters can yield surprising results. Sometimes, adjusting the pressure slightly reveals better bonding properties. Don't shy away from these small changes. Mistakes can provide valuable insights into the process. A flexible approach can lead to improvements that you may not initially consider. Embrace these imperfections as chances for growth in your mastering of Tpt wire bonding technology.

| Tip | Description | Importance Level | Frequency of Use |

|---|---|---|---|

| Optimize Bonding Parameters | Adjust parameters like temperature and speed for ideal bonding. | High | Daily |

| Regular Maintenance | Keep the tool clean and well-maintained to ensure longevity. | Medium | Weekly |

| Training and Skill Development | Invest in proper training for operators for consistency. | High | Monthly |

| Material Compatibility | Ensure materials used are compatible with bonding processes. | High | Daily |

| Quality Control Checks | Implement checks to ensure output meets quality standards. | High | Per Batch |

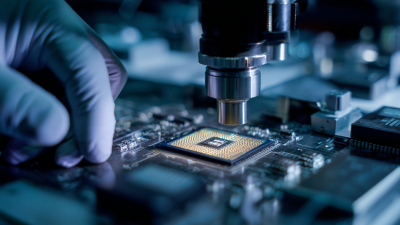

When working with Tpt wire bonding, having the right tools is crucial. A high-quality wire bonder is the centerpiece of your setup. Ensure it has adjustable parameters for heat and pressure. These features help create strong bonds. Alongside the bonder, fine wire spools are necessary. Choose wires with appropriate diameter and material for your specific application.

Performing wire bonding requires attention to detail. A microscope can enhance visibility during the process. Look for defects in bonding, like misalignment or creases in the wire. A clean workspace is equally important. Dust and grime can lead to poor results, so keep tools organized. After every session, reflect on the methods used. Consider what worked and what could be improved.

A reliable power supply ensures consistent performance. Fluctuations can affect the bonding process. Don’t overlook safety equipment, too. Eye protection and gloves are essential to prevent accidents. Each component is interconnected. Missing one can compromise the entire operation. Regularly assess and upgrade your tools to stay efficient.

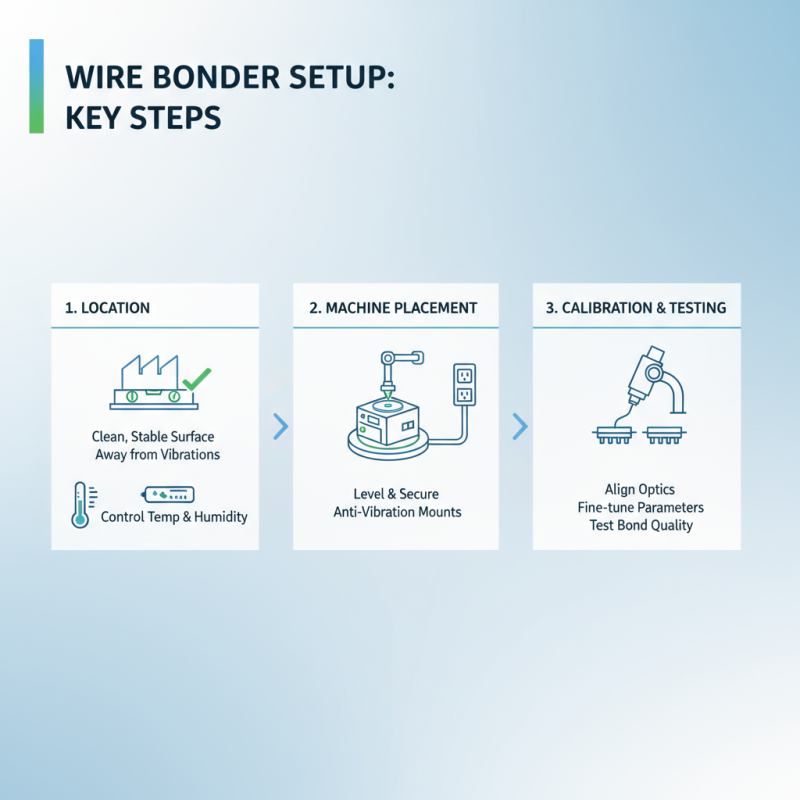

Setting up a wire bonder can be tricky. It requires careful attention to detail. Start by choosing the right location. Make sure the surface is clean and stable. Consider the ambient conditions too. Temperature and humidity can affect performance.

Before powering up, check all connections. Loose wires can lead to malfunctions. Ensure that your tools are within reach. An organized workspace will save you time. Take a moment to read the manual. It may contain vital setup instructions.

As you begin the bonding process, pay attention to the parameters. Adjusting bond force and time is essential. Keep the wire height consistent, but don’t rush. Each bond requires focus and precision. If a bond looks imperfect, don’t hesitate to reflect on your technique. Mistakes can often lead to better results in the long run.

When using a wire bonder, it’s vital to ensure optimal bond quality. Begin by assessing the bonding parameters. Adjust the pressure, time, and temperature for each wire. Often, we overlook how small changes can make a significant impact. For instance, even a slight increase in temperature might improve the bond. However, too much heat can cause damage.

Surface cleanliness is another critical factor. Contaminants like dust or oils can compromise the bond. A quick inspection before starting can save time later. Make it a habit to regularly clean the surfaces. Besides, the choice of bonding wire matters. Different materials behave differently under similar conditions.

Don’t ignore the importance of training. Even experienced operators can benefit from regular workshops. Mistakes happen, and reflection is key. Analyzing failed bonds can lead to better techniques in the future. Develop an atmosphere where feedback is encouraged, as this could enhance productivity and bond strength. Each bond tells a story of the previous attempts and adjustments made.

When using Tpt wire bonders, troubleshooting is essential for optimal performance. Effective wire bonding presents challenges. Many operators face wire lift-off and bond failures. According to industry reports, poor environmental control can lead to a 20% increase in defects. Consistent temperature and humidity levels are crucial.

Tip: Regularly check your environmental conditions. Address fluctuations promptly to ensure quality. Monitor temperature closely. Too high or too low can affect bond strength. A reliable measurement tool is vital for this.

Wires also require careful handling. Targeted pressure during bonding prevents weak connections. Data shows that inconsistent pressure can result in a 30% decrease in bond reliability.

Tip: Adjust your bonding parameters frequently. These can include power settings, speed, and ultrasonic energy. Don’t hesitate to refine these settings for each bond type. Remember, overlooked details often lead to larger problems down the line.

Frequent evaluation of bonding techniques keeps production efficient. Unattended misalignments can escalate costs unexpectedly. Consider documenting common issues for future reference. Adapting to these challenges fosters continuous improvement in the wire bonding process.