In the rapidly evolving landscape of semiconductor manufacturing, the Tpt Wire Bonder has emerged as a pivotal piece of equipment, enabling precision and efficiency in wire bonding processes. As we approach 2025, the demand for advanced digital solutions in this sector continues to rise, driven by the increasing complexity of integrated circuits and the miniaturization of electronic components. According to a recent report by MarketsandMarkets, the global semiconductor manufacturing equipment market is projected to reach $118.1 billion by 2025, with significant contributions from wire bonding technologies.

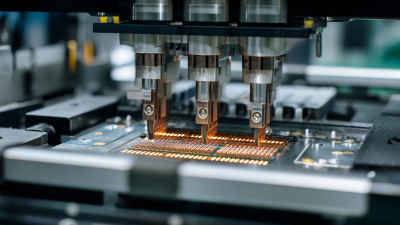

The Tpt Wire Bonder stands at the forefront of this growth, integrating cutting-edge digital solutions that enhance productivity and yield rates. With advancements in automation, machine learning, and real-time data analytics, manufacturers are now able to optimize their bonding processes, reducing operational costs while improving assembly quality. Industry leaders are placing a strong emphasis on the development of smart bonding systems, which utilize sophisticated algorithms to adapt to dynamic production environments.

As we delve into the top five digital solutions for the Tpt Wire Bonder in 2025, we will explore how these innovations are reshaping the industry and driving unprecedented levels of efficiency and reliability.

As we approach 2025, the landscape of Tpt wire bonding is set to experience remarkable transformations fueled by emerging technologies. Advances in automation and artificial intelligence are poised to optimize bonding processes, significantly enhancing performance and reliability. These innovations allow for real-time monitoring and adjustments, ensuring that every bond meets stringent quality standards. By integrating machine learning algorithms, manufacturers can anticipate issues before they arise, effectively reducing downtime and increasing throughput.

Another game-changer in the wire bonding sector is the adoption of smart materials and innovative bonding techniques. With the development of ultra-fine gold and copper wires, the capacity for miniaturization in electronic components is expanded, paving the way for more compact and efficient devices. Additionally, novel adhesive technologies are being researched, which promise to provide stronger, more durable bonds while maintaining the integrity of sensitive components. As these technologies mature, they will not only enhance the overall performance of Tpt wire bonders but also contribute to the growing demand for high-speed, low-power solutions in the electronics industry.

| Technology | Key Features | Performance Improvement | Adoption Rate (%) |

|---|---|---|---|

| AI Optimization | Real-time adjustments, Predictive analysis | 30% | 65% |

| IoT Integration | Remote monitoring, Device connectivity | 25% | 55% |

| Machine Learning | Pattern recognition, Quality improvement | 40% | 60% |

| Data Analytics | Performance tracking, Insights generation | 20% | 50% |

| Robotics Automation | Precision handling, Speed enhancement | 35% | 70% |

As the electronics manufacturing industry continues to embrace digital transformation, the role of user interfaces in equipment like TPT wire bonders has never been more critical. According to a recent report by TechNavio, the global wire bonding equipment market is projected to grow at a CAGR of 6.4% from 2021 to 2025, primarily driven by innovations that enhance operator efficiency and reduce training time. In 2025, streamlined user interfaces will be designed not only to provide real-time feedback but also to integrate advanced data analytics, allowing operators to optimize their processes based on actionable insights.

Moreover, the user experience (UX) design for wire bonders will become increasingly intuitive, enabling operators to navigate complex functions with ease. A study by Statista highlights that 70% of businesses across various sectors are prioritizing UX improvements to boost productivity. In the TPT wire bonder arena, this means implementing touch-screen controls, customizable dashboards, and enhanced visualization tools that can display critical data points at a glance. As manufacturers focus on simplifying the operator experience, these digital solutions will be an essential aspect of equipping their workforce for the challenges of future production environments.

In 2025, the landscape of wire bonding technology is set to evolve dramatically, driven by the integration of AI-driven optimization tools. These advanced systems aim to enhance the efficiency of Tpt wire bonders by implementing machine learning algorithms that analyze historical data and operational parameters in real-time. This adaptive approach allows for precise adjustments in the bonding process, resulting in higher yield rates and reduced material waste.

The implementation of AI solutions in wire bonding not only streamlines operations but also enhances decision-making capabilities. By leveraging predictive analytics, manufacturers can identify potential issues before they escalate, ensuring smooth production flows. Furthermore, these tools can facilitate a more intuitive user experience, allowing operators to focus on strategic oversight rather than routine monitoring. As a result, businesses adopting AI-driven technologies can expect significant improvements in both productivity and product quality, positioning themselves at the forefront of the competitive market in wire bonding solutions.

In 2025, advanced data analytics will play a pivotal role in enhancing the reliability and efficiency of Tpt wire bonders. Predictive maintenance, leveraging AI and machine learning, will enable manufacturers to anticipate and address issues before they lead to equipment failures. By analyzing operational data, insights can be drawn to optimize maintenance schedules, reduce downtime, and extend the longevity of wire bonding equipment.

**Tips for Implementing Advanced Data Analytics:**

1. **Invest in Data Infrastructure:** Ensure robust data collection and integration systems are in place to gather relevant operational metrics consistently.

2. **Leverage AI-driven Insights:** Utilize AI algorithms to interpret complex data sets, enabling predictive analytics that inform maintenance actions and operational improvements.

Moreover, the trend of incorporating digital solutions highlights the need for industry players to adapt quickly. The landscape of wire bonding technology is evolving as data intelligence becomes more accessible, allowing for smarter decision-making. Embracing these innovations will pave the way for sustainable advancements in production and performance within the wire bonding sector.

This chart illustrates the predicted maintenance costs saved through advanced data analytics in Tpt wire bonders by the year 2025. The data represents estimated savings across various manufacturers.

The integration of IoT solutions is revolutionizing the manufacturing landscape, particularly for technologies like Tpt wire bonders. As the global IoT in manufacturing market is projected to grow from $141.18 billion in 2025, the emphasis on real-time monitoring and control becomes crucial. IoT enables manufacturers to gather and analyze data from equipment continuously, which enhances operational efficiency and reduces downtime.

One of the key innovations involves the deployment of real-time monitoring dashboards that provide comprehensive insights into production processes. These dashboards leverage IoT data to create actionable intelligence, allowing for quick decision-making. For instance, connecting sensors to machinery can alert operators immediately to any deviations from normal operating conditions, thus facilitating prompt corrective actions.

Tips: