In the realm of semiconductor manufacturing, understanding "Wire Guides and Ribbon Guides for Wire Bonders" is crucial. An effective bonding operation relies heavily on these guides, which direct wire placement. According to a recent industry report, improper guide usage can lead to defects in over 30% of wire bonding processes.

Expert John Smith, a renowned figure in the field, states, "The choice of wire and ribbon guides directly impacts the reliability of the bonds." This highlights the significance of analyzing and selecting the right guides for optimal outcomes. Even minor misalignments can result in costly rework and production delays.

The ongoing evolution of materials and techniques poses challenges for engineers. It's vital to remain adaptable and continually assess guide performance. A commitment to innovation is necessary but not sufficient; diligent testing and user feedback also drive improvements.

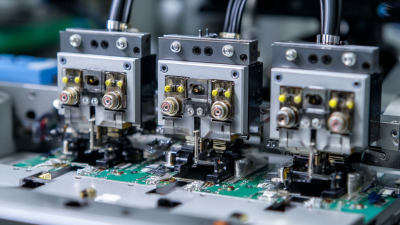

Wire guides play a crucial role in wire bonding efficiency. Their design directly impacts the precision and quality of the bonding process. Proper alignment helps prevent wire breakage and ensures that connections are strong and reliable. If the guides are not well-configured, issues arise. Misalignment can lead to inconsistent bonds, affecting overall product performance.

Using the right materials for wire guides is essential. Materials should withstand heat and stress during bonding. Not every guide holds up under various conditions. There is a risk of wear, leading to increased maintenance and potential downtime. In some cases, operators overlook these details, focusing instead on the bonding process itself. This oversight can result in costly errors down the line.

Adjusting wire guides requires careful attention. Operators often need to recalibrate their techniques based on wear and tear. Regular checks can reveal hidden issues that affect efficiency. It’s easy to miss small changes in performance until they escalate. These adjustments require focus, but they can significantly enhance overall bonding quality and longevity.

| Guide Type | Material | Diameter Compatibility (mm) | Max Temperature (°C) | Key Features |

|---|---|---|---|---|

| Wire Guide | Ceramic | 20 - 30 | 1000 | High thermal stability |

| Wire Guide | Teflon | 15 - 28 | 250 | Low friction surface |

| Ribbon Guide | Stainless Steel | 30 - 50 | 800 | Corrosion resistant |

| Ribbon Guide | PCTFE | 25 - 45 | 150 | Excellent dielectric properties |

Material selection plays a crucial role in wire bonding processes. The type of materials used for wire guides and ribbon guides can significantly impact performance. Different materials have unique attributes that affect durability, thermal stability, and conductivity. For instance, some materials may be too brittle. This can lead to fractures during bonding, resulting in yield loss.

Wire guides made from softer materials may deform under pressure. This can lead to inconsistent placement of the wires. On the other hand, selecting a material that is too rigid may cause unexpected breaks. It's a balancing act between strength and flexibility. The manufacturing environment also matters. Environmental factors like humidity and temperature can influence material behavior.

Often, engineers use standard materials without considering specific application requirements. This can lead to suboptimal performance. Experimenting with different materials can yield insights. It may help in achieving better bonding quality and reliability. Observations and data collection during trials are key. They can reveal unexpected results, prompting necessary adjustments to material choices. Engaging in this reflective process enhances expertise and improves outcomes.

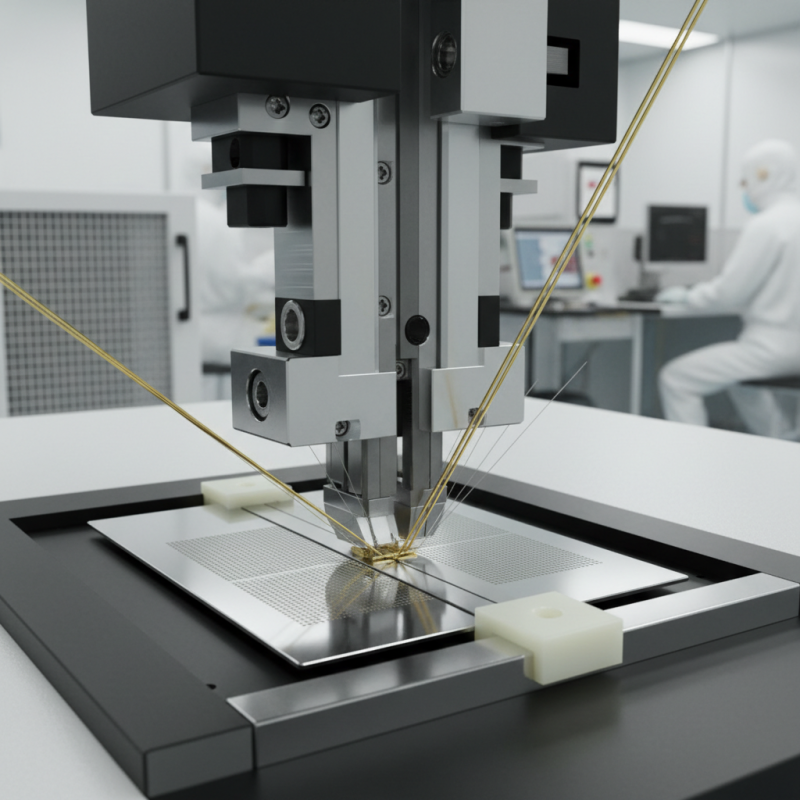

When designing optimal ribbon guides, reliability should be the top priority. Engineers must consider several factors to ensure effective wire bonding. A well-designed ribbon guide minimizes misalignment during the bonding process. Any small deviation can lead to failures in the connections. Attention to detail is crucial in materials selection, as the right material can enhance durability and performance.

Another key aspect is the height of the ribbon guide. It needs to be adequate for various bonding scenarios. If the height is too low, wires may not bond correctly. If it’s too high, it may lead to unnecessary stresses on the wire. There is always a trade-off that engineers must navigate. Balancing these factors requires a deep understanding of both the technology and the application at hand.

Additionally, testing and iteration are essential. Initial designs may look perfect on paper but fail during real-world applications. Engineers should remain open to adjustments based on feedback. Continuous refinement can lead to better designs that withstand the test of time. Creating reliable ribbon guides is not just about choosing materials; it's about understanding the entire bonding process.

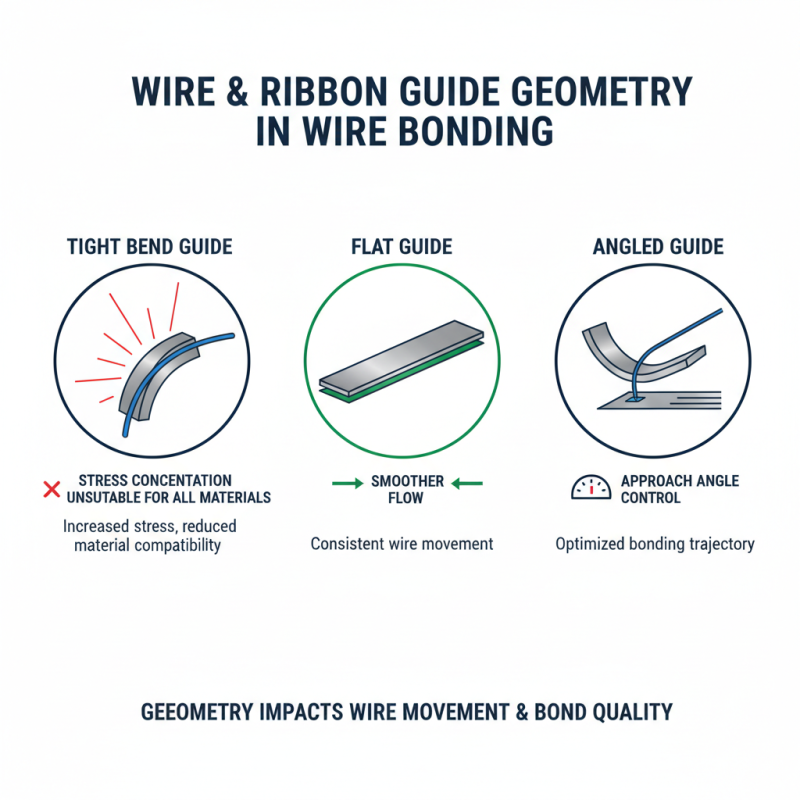

The design of wire and ribbon guides plays a crucial role in wire bonding outcomes. The geometry of these guides affects wire movement and bonding quality. For instance, a tighter bend can lead to stress concentrations. This might not always be ideal for certain materials. A flat guide could promote smoother wire flow but may limit the approach angle.

When selecting guide geometry, consider the bond area and wire type. A guide that is too rigid may cause damage during the bonding process. Using a flexible design helps minimize the risk of defects. However, flexibility needs to be balanced with stability. If a guide wiggles too much, that can introduce errors.

Observing the outcomes of different guide shapes reveals valuable insights. Poor results can stem from negligence in geometry selection. Regularly reviewing bonding samples may highlight patterns related to guide design. Adjustments based on these findings can improve future efforts. There is always room for trial and error in optimizing wire bonding techniques.

Wire bonding is a crucial process in electronics manufacturing. However, common defects can arise if not carefully managed. One significant factor influencing bonding quality is the type of guides used during the process. Wire guides and ribbon guides play a pivotal role in ensuring correct alignment and tension. Misalignment can lead to inconsistent bond quality, and too much tension can even break the wire.

Inadequate guide usage can cause defects like ball bond lift-off or excessive wire sweep. These issues often arise during high-speed operations where precision is key. When guides are improperly set, both operators and machines face challenges.

Often, workers may overlook the minor adjustments needed, leading to significant consequences. A flawed process could result in increased production costs and wasted materials.

It's important to regularly assess your guiding system. Consider different guide designs and materials; each may offer unique benefits. By being mindful of the setup, operators can minimize defects. Regular training and awareness can also help mitigate issues.

A thorough evaluation process is often overlooked yet essential for improving wire bonding outcomes and preventing defects.