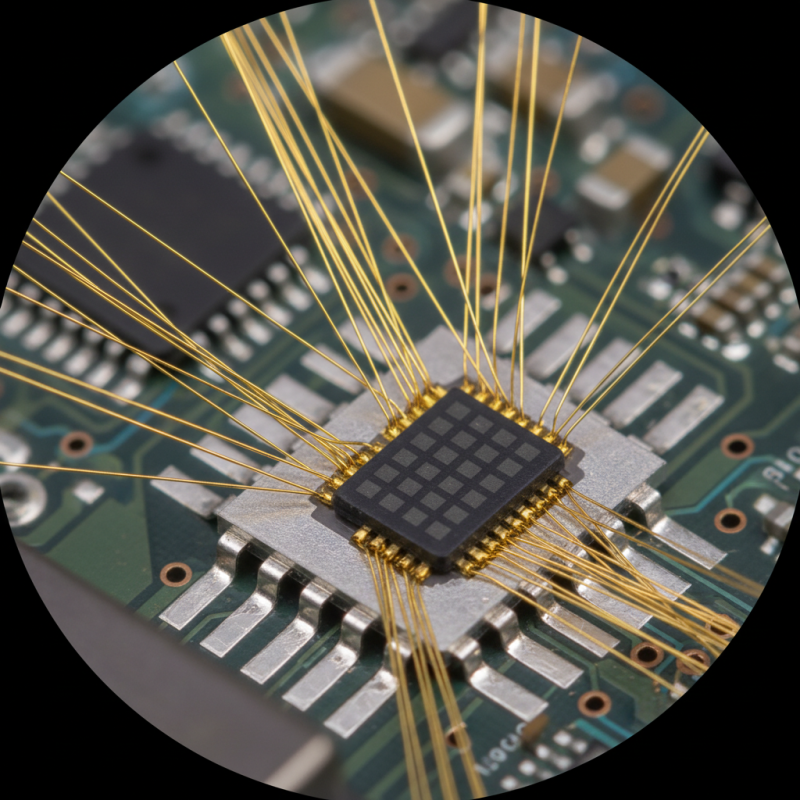

Gold Wire Bonding is a crucial process in the production of electronic components. This method offers remarkable benefits over other bonding techniques. It utilizes thin gold wires to connect semiconductor chips to their packages. This provides excellent conductivity and reliability.

One of the key advantages of Gold Wire Bonding is its durability. Gold resists corrosion and oxidation, ensuring a longer lifespan for electronic devices. However, not all applications may benefit equally from this technique. In some cases, cost may be a significant factor.

Additionally, while Gold Wire Bonding is prevalent, it's not without its challenges. Achieving optimal bond strength requires precise conditions. A misstep can lead to weak connections. Thus, careful consideration is necessary before choosing this method.

Gold wire bonding has become a crucial technology in semiconductor packaging. One key advantage is its excellent conductivity. Gold has one of the highest electrical conductivities among metals. According to a report by the International Journal of Electrical Engineering, gold wire bonding achieves an impressive reliability rate of over 95% in various environments. This performance is vital for high-frequency applications, where efficient signal transmission is essential.

Moreover, gold wire bonding is known for its mechanical flexibility. This is particularly beneficial in applications that experience thermal expansion. A study published in the Journal of Semiconductor Manufacturing indicates that gold wire bonds can endure a temperature range from -60°C to 200°C without significant degradation. The ability to withstand such conditions is crucial for maintaining device integrity. However, one must consider the balancing act between cost and performance. Gold is more expensive than other materials like aluminum, leading to potential cost concerns in large production runs.

Recent advancements in bond technology further enhance gold wire's appeal. However, challenges remain. Proper training and techniques are vital to prevent bonding defects. These issues can irritate engineers and lead to increased manufacturing costs. Overall, the benefits of gold wire bonding in semiconductor packaging are clear, yet aware of the potential pitfalls is essential for optimal production outcomes.

Gold wire bonding remains a popular choice for electronics due to its unique advantages. Compared to ultrasonic and thermocompression bonding methods, gold wire bonding shows superior conductivity. This is critical for high-performance applications. It’s also more resistant to corrosion, making it ideal for harsh environments. However, gold's higher cost can be a drawback for budget-conscious projects.

When considering alternatives, aluminum wire bonding often comes up. Aluminum is cheaper, yet it lacks the conductivity of gold. Sometimes, designers overlook the long-term benefits of gold bonding in favor of immediate savings. This choice might lead to costly repairs down the road. Additionally, some bonding techniques require specific equipment. This adds to the overall complexity.

Another point to reflect on is the production yield. Inconsistent wire bonding can lead to failures. Gold’s flexibility allows for easier handling, potentially improving yield rates. This can be crucial in high-volume production. Missteps in bonding method selection could impact overall device performance. Choosing the right wire bonding method is not always straightforward. It requires careful consideration of factors beyond just material costs.

Gold wire bonding is a popular choice in various electronic devices. It is widely used in semiconductor packaging, offering excellent conductivity and reliability. Many smartphone manufacturers use gold wire bonding to connect chip components. Its effectiveness helps ensure the durability and performance of these devices.

In medical devices, gold wire bonding plays a crucial role. It is utilized in implants and diagnostic equipment. The high corrosion resistance of gold is essential in these applications. However, one must consider the cost. Gold is more expensive than other bonding materials, which can be a drawback for some manufacturers.

A balance between cost and performance is important. The benefits of gold wire bonding usually outweigh its higher price in critical applications. Using gold can enhance device performance and longevity. But companies need to reflect on their budgets and needs before implementation. Ultimately, gold wire bonding presents unique advantages while posing some challenges, making it vital to evaluate each case thoroughly.

| Application Area | Key Features | Benefits | Example Products |

|---|---|---|---|

| Consumer Electronics | High conductivity, flexibility | Improved performance, durability | Smartphones, tablets |

| Automotive | Resistance to corrosion | Longer lifespan, safety | ECUs, sensors |

| Telecommunications | Reliable connections | Enhanced signal integrity | Base stations, routers |

| Medical Devices | Biocompatibility | Safety and accuracy | Implantable devices, diagnostic tools |

| Aerospace | High reliability | Critical for safety | Flight control systems, satellites |

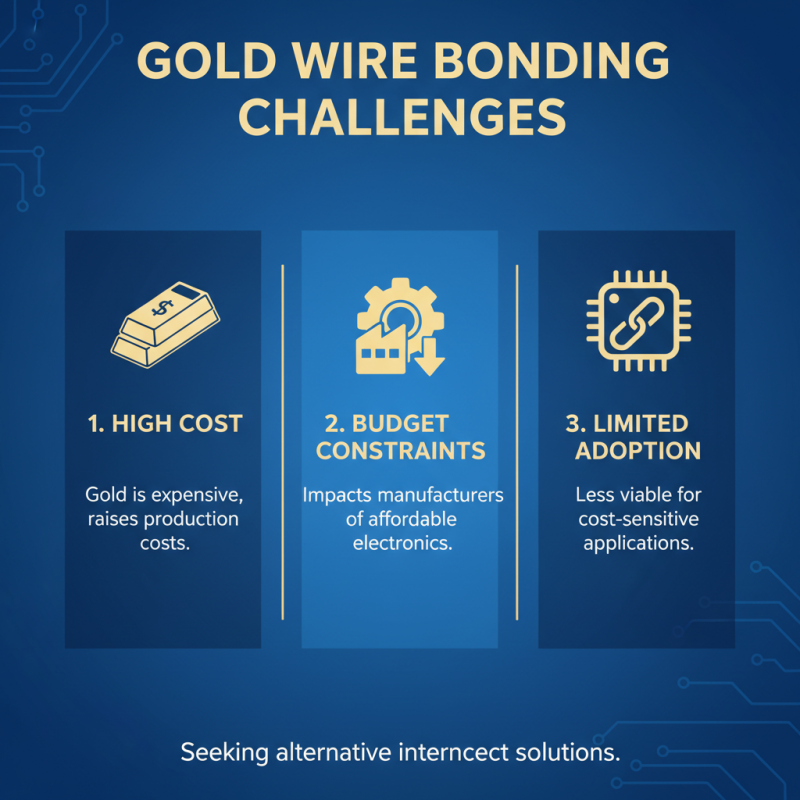

Gold wire bonding is a popular choice in electronics. It offers excellent conductivity and reliability. However, cost plays a crucial role in the decision-making process.

Using gold wire can increase production costs. Gold prices fluctuate significantly, impacting overall budgets. Manufacturers must weigh the benefits against these expenses. For some, the investment means higher quality. For others, it may be a stretch too far.

In addition, the intricacies of the bonding process can create hidden costs. Skilled labor is required to ensure proper execution. Mistakes can lead to failures, further driving up costs. Despite these challenges, many continue to opt for gold wire. The question remains: is it worth the price?

Gold wire bonding is a popular method in electronics. However, it comes with challenges. One major limitation is the cost. Gold is expensive, and this can drive up production costs significantly. This affects manufacturers, especially those focused on budget-friendly solutions.

Another challenge is the bonding process itself. The technique requires precision and specific conditions. High temperatures or humidity may lead to bonding failures. Moreover, equipment for gold wire bonding can be complex and require regular maintenance. This might not be feasible for smaller operations. Additionally, there can be issues with wire thickness. Thinner wires may break during the bonding process, while thicker ones can be difficult to manipulate.

Sustainability is another area to consider. The mining process for gold has environmental impacts. As manufacturers seek greener practices, this raises questions about long-term viability. In conclusion, while gold wire bonding offers advantages, these challenges need careful evaluation. Each issue sparks a need for reflection and improvement in the industry.