In the rapidly evolving realm of microelectronics, Wedge Bonding Tools have emerged as pivotal components in enhancing connectivity and efficiency in various applications. As highlighted by Dr. Emily Chen, a leading expert in semiconductor packaging, "The precision and reliability of Wedge Bonding Tools are crucial for advancing miniaturization and performance in electronic devices." This sentiment underscores the significance of understanding not only the tools themselves but also their potential benefits and applications within the industry.

Wedge Bonding Tools operate on the principle of creating strong and durable connections between electronic components, particularly where space is limited and performance is paramount. Their versatility finds utility in sectors ranging from automotive electronics to telecommunications, reflecting broad adoption in today’s technology-driven landscape. This comprehensive guide will delve into the unique features of Wedge Bonding Tools, exploring how they contribute to innovative solutions while addressing the ongoing challenges faced by engineers and manufacturers in the field.

Wedge bonding is a widely utilized interconnect technology primarily in the semiconductor and microelectronics industries. At its core, wedge bonding refers to the process of connecting two surfaces through the use of a wedge-shaped tool that applies ultrasonic energy to form a bond. This method typically involves bonding wire to metal pads on chips or substrates, allowing for a reliable and robust connection that is essential for device functionality.

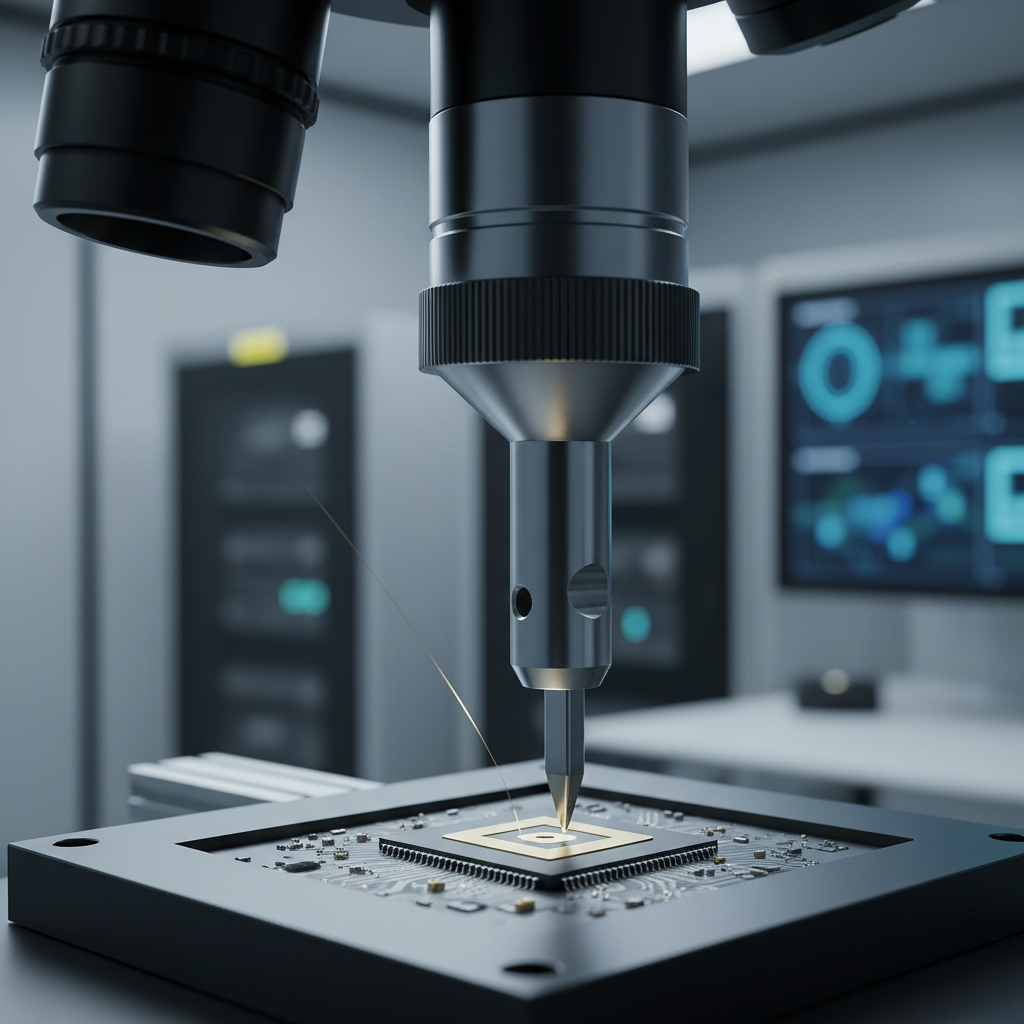

The process begins with the precise alignment of the wedge tool over the designated bonding site. Once positioned, the tool applies pressure while simultaneously vibrating at ultrasonic frequencies, which generates localized heating. This thermal energy softens the materials, enabling molecular bonding without the need for solder or adhesives. Wedge bonding is particularly favored for its low thermal impact on heat-sensitive components and its ability to create strong, permanent connections with minimal footprint, making it ideal for compact electronic designs.

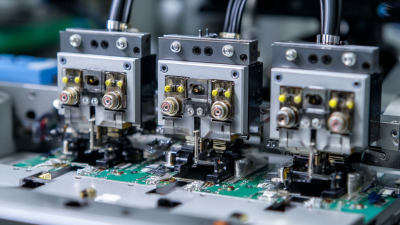

Wedge bonding tools play a crucial role in the electronics manufacturing sector, particularly in applications that require precise and reliable connections. One of the primary applications of wedge bonding is in the assembly of semiconductor devices, where fine wires are bonded to chip pads. This technique is preferred for its ability to handle high interconnect density and its compatibility with various materials, allowing for the production of compact and efficient electronics.

Additionally, wedge bonding is widely used in the automotive industry, where robust and reliable connections are essential. The process ensures that electronic components can withstand harsh environmental conditions such as high temperatures and vibrations, making it ideal for automotive sensors and control units. Moreover, wedge bonding's adaptability extends to medical devices, where biocompatibility and precision are paramount. The consistent performance of wedge bonding tools contributes significantly to the reliability and longevity of these critical applications in electronics manufacturing.

Wedge bonding is an advanced interconnect technology that offers numerous advantages in the manufacturing and assembly of electronic components. One prominent benefit is its efficiency. Unlike traditional bonding methods, wedge bonding allows for faster cycle times, which can significantly enhance productivity. By utilizing a process that requires less clamping force and avoids the use of additional adhesives, manufacturers can streamline operations, thereby reducing time-to-market for their products.

Reliability is another key benefit that positions wedge bonding as a preferred choice for modern electronic applications. The mechanical strength of wedge bonds, combined with their resistance to thermal and mechanical stresses, ensures long-lasting connections in a wide range of environments. This is particularly crucial in industries where durability is paramount, such as automotive and aerospace.

Tips: When considering wedge bonding for your projects, it's essential to assess the specific requirements of your application. Choose the right materials that align with the operating conditions to maximize the benefits of this technology. Additionally, investing in high-quality wedge bonding tools can improve the precision and consistency of your bonds, leading to even greater reliability.

Wedge bonding is a specialized technique employed in the semiconductor industry, especially in the packaging of integrated circuits. The method utilizes a thin metal wire, typically gold or aluminum, which is bonded to the die and substrate through a process that manipulates the wedge shape of the bonding tip. In a recent report by MarketsandMarkets, the wedge bonding market is projected to reach $3.1 billion by 2025, reflecting the growing adoption of this technology over other methods such as ball bonding and flip-chip bonding.

When comparing wedge bonding to other bonding techniques, several factors come into play. Wedge bonding offers superior strength and reliability, particularly in high-stress environments, making it ideal for applications in automotive and aerospace electronics. A study published in the IEEE Transactions on Components, Packaging, and Manufacturing Technology highlighted that wedge bonding provides better thermal and electrical performance, with a failure rate reduction of up to 30% compared to traditional ball bonds when subjected to thermal cycling tests. Moreover, wedge bonding is less sensitive to contamination, which further enhances its advantages in cleanroom environments compared to flip-chip bonding, which requires more stringent conditions.

The future of wedge bonding technology is set to witness significant advancements that could reshape the semiconductor manufacturing landscape. Innovations in materials and techniques are expected to enhance the efficiency and reliability of wedge bonding processes. As manufacturers seek to increase production speeds and reduce costs, developments in automation and precision measurement technologies will play a pivotal role in optimizing wedge bonding operations. This shift towards automation not only minimizes human error but also allows for greater scalability of the bonding process, making it an attractive option for high-volume production.

In terms of market potential, the demand for advanced packaging solutions is escalating, driven by the proliferation of consumer electronics, automotive applications, and the Internet of Things (IoT). Wedge bonding, known for its versatility and ability to connect different substrates, is well-positioned to cater to these evolving needs. Furthermore, as industries increasingly prioritize miniaturization while maintaining high performance, the benefits of wedge bonding—such as improved thermal management and electrical connectivity—are likely to attract more investments. Consequently, the intersection of innovation and market demand will cultivate a thriving ecosystem for wedge bonding technologies in the coming years.