In an increasingly competitive global market, the demand for high-quality manufacturing tools has never been more critical. This blog delves into the advancements in Chinese Die Pick Up Tools and Collets that are setting new standards for excellence and reliability. With a firm commitment to quality, China's manufacturing sector has made significant strides, leading the charge in providing top-notch products that meet the needs of best-selling brands worldwide. As we explore the innovative designs, superior materials, and state-of-the-art production techniques behind these tools, we will highlight how they enhance efficiency and precision in various industries. Join us as we focus on the evolution and global impact of Die Pick Up Tools and Collets, showcasing how dedication to quality and craftsmanship positions Chinese manufacturers at the forefront of the export market.

The quality of die pick-up tools and collets is paramount in the manufacturing sector, particularly in industries reliant on precision engineering. According to a recent industry report by MarketsandMarkets, the global market for industrial tools, including die pick-up tools, is projected to reach USD 193 billion by 2027, with an annual growth rate of 5.2%. This growth underscores the increasing demand for high-quality tooling solutions to enhance efficiency, reduce downtime, and improve overall production accuracy.

In the context of Chinese manufacturing, the emphasis on quality is more critical than ever. The 2022 Global Manufacturing Competitiveness Index highlighted that countries that invest in quality control and innovative tooling techniques tend to outperform their counterparts in efficiency and productivity. Chinese manufacturers, recognizing this trend, have begun upgrading their tooling products, particularly die pick-up tools and collets, to meet international quality standards. By incorporating advanced materials and production techniques, they are not only improving reliability but also ensuring that products can withstand the rigors of modern manufacturing processes, thus addressing the global demand for superior tooling solutions.

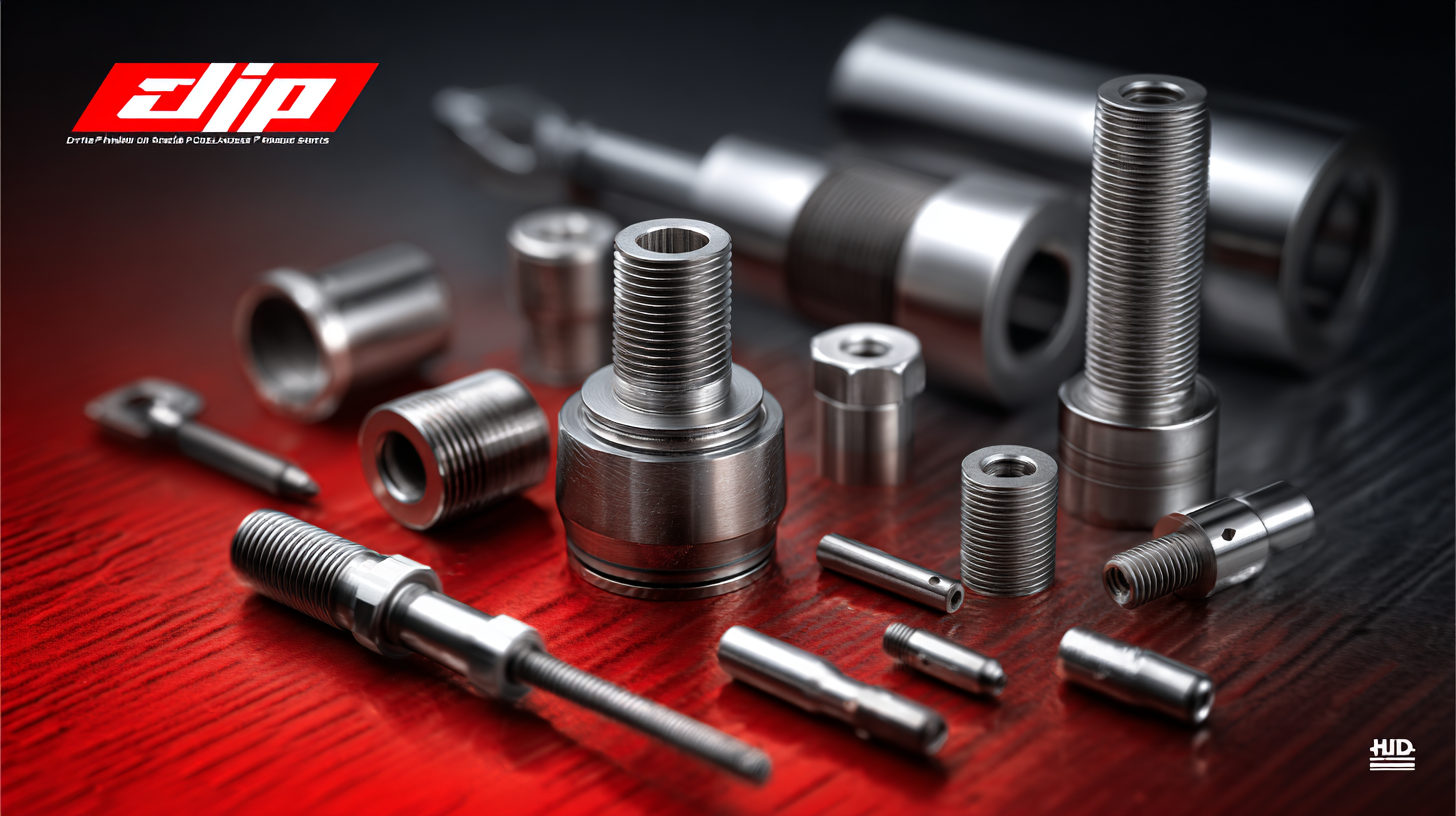

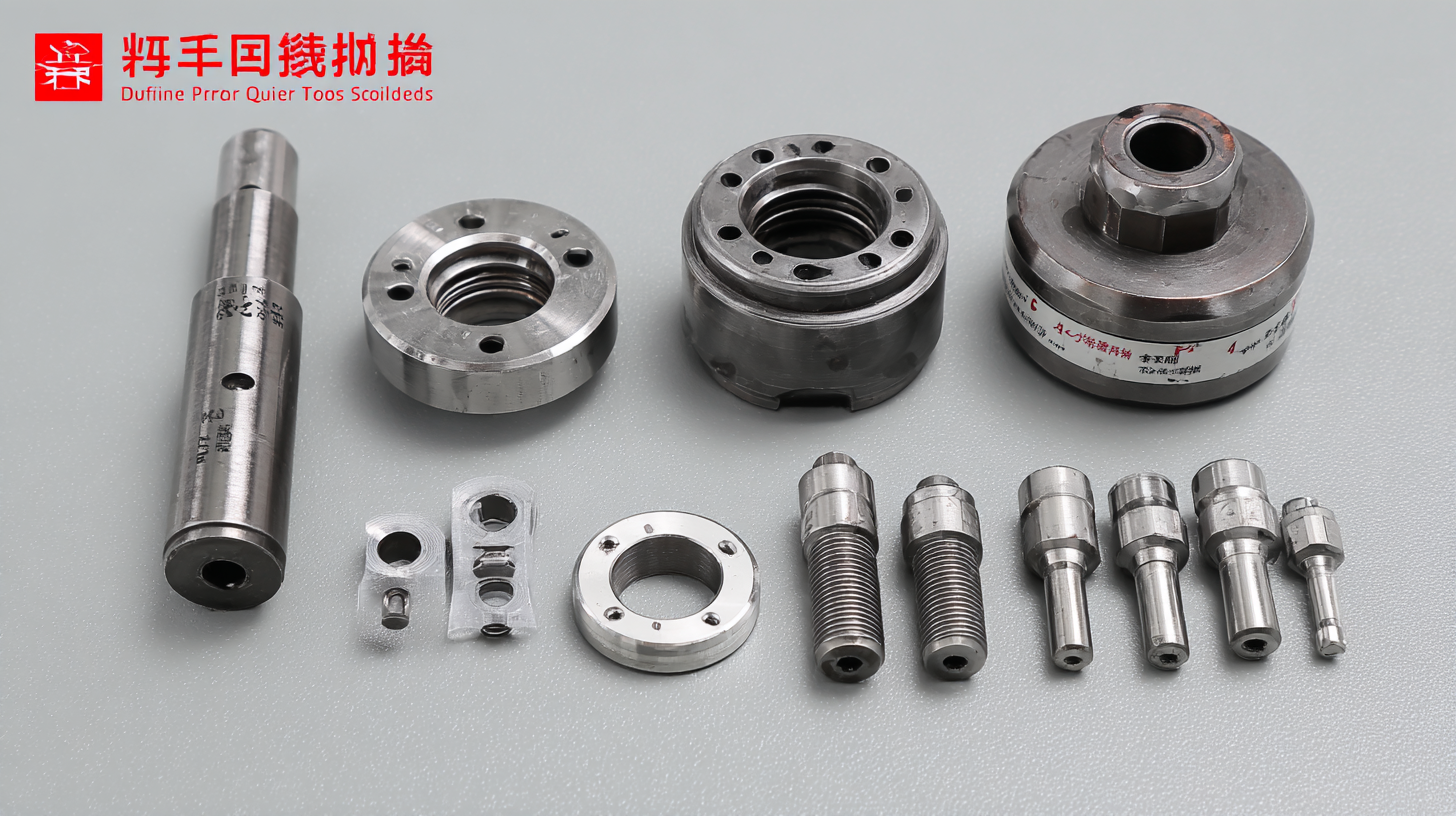

When selecting upgraded die pick up tools, there are several key features that enhance performance and ensure reliability in various applications. Firstly, the material construction is vital; tools made from high-grade steel or advanced alloys provide increased durability and resistance to wear and corrosion. This durability translates to a longer lifespan and consistent performance, reducing downtime in production processes.

Another essential feature is the ergonomic design of the tools. Comfort during use can significantly impact productivity, especially in high-volume settings. Tools with anti-slip grips and lightweight compositions allow for better control and reduced fatigue, enabling operators to maintain precision over extended periods. Furthermore, the versatility of collets should not be overlooked. Having a range of compatible collets ensures that users can cater to different die sizes and shapes, enhancing the tool's overall functionality in diverse manufacturing environments.

These features collectively contribute to the comprehensive performance sought by industry professionals, making upgraded die pick up tools a worthwhile investment.

When it comes to the world of die pick up tools, global bestsellers often set the standard for quality and performance. A comparative analysis of these models reveals significant variations in design, materials, and functionality that can influence both usability and durability.

Leading brands are consistently innovating to meet the demands of end-users, resulting in tools that not only enhance efficiency but also ensure precision in various applications. For instance, some tools employ advanced ergonomic designs, reducing user fatigue during prolonged use, while others focus on superior grip and control, catering to different operational requirements.

Additionally, materials play a crucial role in differentiating these bestselling models. Premium-grade steel is a common choice among top manufacturers, offering enhanced strength and resistance to wear over time. Meanwhile, some brands incorporate high-tech coatings to improve corrosion resistance and longevity, making their die pick up tools suitable for harsh environments. By examining these features and their implications, users can make well-informed decisions tailored to their specific needs, ultimately leading to increased productivity and satisfaction in their projects.

Maximizing the efficiency of die pick up tools requires an understanding of best practices that can significantly enhance your workflow. First and foremost, familiarizing yourself with the specific characteristics of the tools and collets is essential. This knowledge allows you to select the right tool for the job, ensuring optimal performance and reducing the risk of damage to both the tools and the components being handled.

Tip 1: Always inspect your die pick up tools before use. Check for signs of wear and ensure that the collets are clean and free from debris. This simple step can prevent malfunctions and improve accuracy during operation.

Tip 2: Utilize a systematic approach when using die pick up tools. Organizing your workspace and establishing a clear sequence of operations can help streamline processes and reduce downtime. Consider labeling your tools and creating checklists to maintain consistency.

Implementing these strategies can lead to improved productivity and precision in your work, making the most of these upgraded tools in your operations.

When it comes to maximizing the lifespan of die pick-up tools and collets, proper maintenance is key. According to a report by the Precision Tooling Institute, regular cleaning and inspection can extend tool life by up to 40%. Dust and debris accumulation can lead to uneven wear, so utilizing a fine-bristle brush or specialized cleaning solutions regularly can make a significant difference.

When it comes to maximizing the lifespan of die pick-up tools and collets, proper maintenance is key. According to a report by the Precision Tooling Institute, regular cleaning and inspection can extend tool life by up to 40%. Dust and debris accumulation can lead to uneven wear, so utilizing a fine-bristle brush or specialized cleaning solutions regularly can make a significant difference.

Additionally, lubrication plays a crucial role in maintaining the functionality of these tools. The same report highlights that tools experiencing adequate lubrication last, on average, 30% longer than their inadequately maintained counterparts. High-quality synthetic lubricants, suited for the operational environment, can reduce friction and prevent corrosion, ensuring that both pick-up tools and collets maintain optimal performance.

Lastly, it is vital to store tools in a controlled environment. Fluctuations in temperature and humidity bear a substantial impact on the longevity of precision tools. Research indicates that tools stored in stable, climate-controlled conditions retain their quality and functionality longer, minimizing the risk of rust and deformation. Investing in appropriate storage solutions can thus enhance the durability of your die pick-up tools and collets significantly.