In the rapidly advancing field of electronics, selecting the right Tpt Wire Bonder is crucial for optimizing manufacturing processes and ensuring product reliability. As industry expert Dr. Emily Jensen, a leading researcher in semiconductor technology, aptly states, "Choosing the appropriate Tpt Wire Bonder can significantly impact the overall quality and efficiency of your production line." It is imperative for manufacturers to carefully assess their specific needs and constraints before making a decision.

With a myriad of options available in the market, understanding how to navigate the selection process can be overwhelming. Factors such as bonding requirements, material compatibility, and production volume play pivotal roles in determining the most suitable Tpt Wire Bonder for your applications. By exploring essential tips and guidelines, you can make an informed choice that aligns with your operational goals and achieves optimal performance in wire bonding tasks.

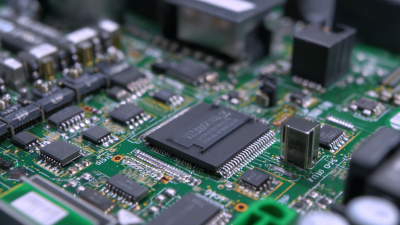

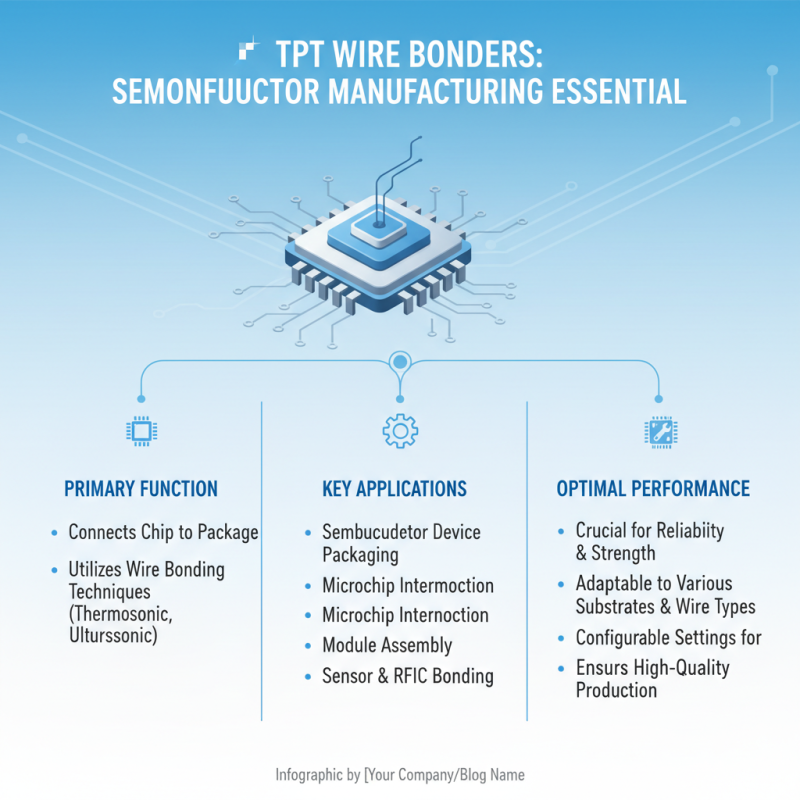

Tpt wire bonders are essential tools in the semiconductor industry, primarily used for connecting the chip to its package. These machines utilize various bonding techniques, such as thermosonic or ultrasonic bonding, depending on the material properties and desired bond strength. Understanding the applications of Tpt wire bonders is crucial for selecting the right model that aligns with specific production needs. Different configurations and settings allow users to adapt the bonding process to accommodate various substrates and wire types, ensuring optimal performance and reliability.

When considering the applications of Tpt wire bonders, one must take into account the assembly requirements of the electronic device being manufactured. Factors such as the size of the wire, the operating environment, and thermal sensitivity of components play significant roles in determining the best bonding method. For instance, in high-frequency applications, achieving a low-interference bond is paramount, which might necessitate particular settings on the bonder. Furthermore, advancements in technology have led to specialized bonders that can handle multi-die assemblies or accommodate advanced materials, offering enhanced versatility for diverse production scenarios.

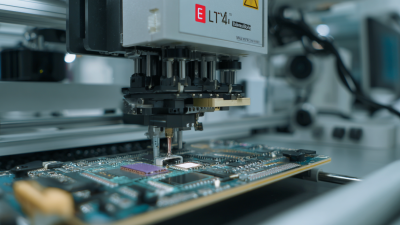

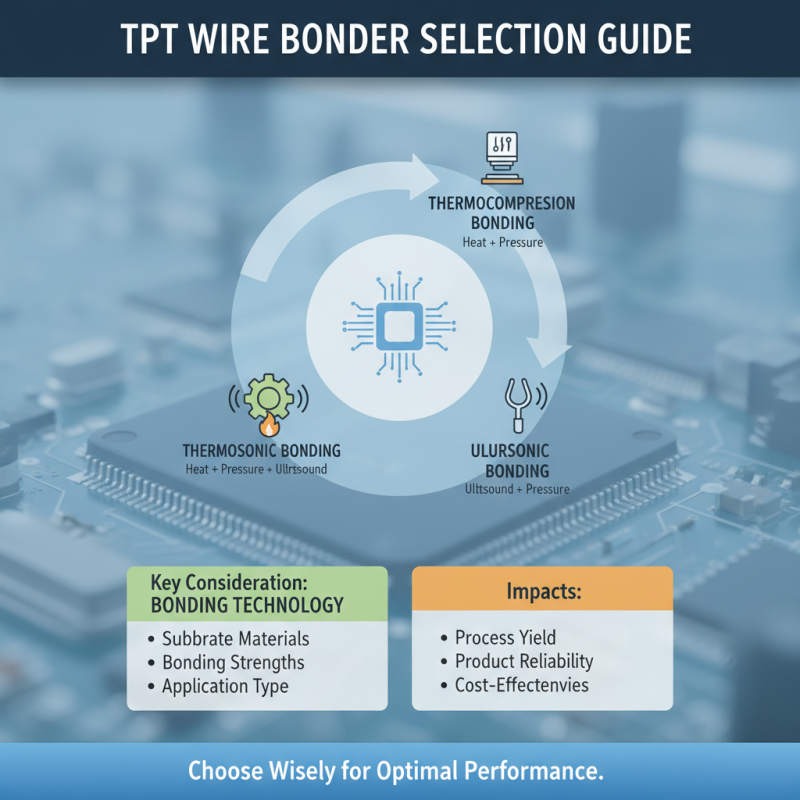

When selecting the right Tpt wire bonder for your specific needs, there are several key factors to consider that can significantly impact your decision-making process. First and foremost, the type of bonding technology employed by the wire bonder is crucial. Options may include thermosonic, thermocompression, and ultrasonic bonding, each offering distinct advantages depending on the materials and assembly requirements of your project. Understanding the bonding techniques and how they interact with various substrates will help you select a machine that aligns with your technical specifications.

Another critical aspect to evaluate is the machine's capability regarding wire size and material compatibility. The wire bonder should be versatile enough to handle the specific gauge and type of wire you plan to use, whether gold, aluminum, or copper. Furthermore, consider the machine's settings and adjustments that facilitate fine-tuning for precise wire placement and bond strength. Additional features such as automated calibration and process monitoring can enhance the reliability of the bonding process, ensuring high-quality results and reducing the likelihood of defects. Evaluating these factors will help you make an informed decision tailored to your production needs.

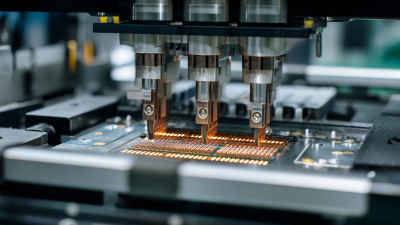

When selecting a Tpt wire bonder, it is crucial to understand the various types available and their unique capabilities. Tpt wire bonders can generally be classified into three categories: ball bonders, wedge bonders, and gold bonders. Each type serves different applications depending on wire material and bonding methods. According to a report by the International Microelectronics Assembly and Packaging Society, the ball bonder segment is particularly popular for applications requiring high-purity gold wires, with over 45% market share due to their efficiency in producing reliable interconnections.

Wedge bonders, on the other hand, are favored in automotive and telecom sectors for their ability to work with aluminum wires, which are crucial for cost-effective production. Data from an extensive market analysis by Technavio indicates that the demand for wedge bonding is expected to grow by 6.2% annually over the next five years, driven by advancements in semiconductor packaging technology. Additionally, gold bonders, often used in high-frequency applications, continue to see steady growth as manufacturers push for more durability and performance in their bonding processes.

When choosing the right Tpt wire bonder, it’s essential to consider these distinctions, along with factors such as material compatibility and the required bond strength for your specific applications. By evaluating the strengths and limitations of each type, you can better align your needs with the most suitable technology, thereby optimizing production efficiency and product reliability.

When evaluating technical specifications and features of wire bonders, it’s crucial to consider the specific applications and materials you will be working with. The choice between thermosonic and ultrasonic bonding processes can significantly influence the quality and reliability of your connections. It's essential to assess the temperature and ultrasonic frequency ranges that the wire bonder can handle, ensuring it aligns with the requirements of your project.

Another critical feature to evaluate is the machine's accuracy and repeatability. High precision is necessary for applications requiring delicate handling of fine wires, and features like programmable parameters can enhance usability. Additionally, consider the versatility of the wire bonder. A machine that can adapt to different bond types or wire diameters provides flexibility for various projects, making it a valuable addition to your production line.

In making your selection, keep in mind the importance of user-friendly interfaces and support services. A well-designed interface can streamline operation, while reliable customer support is vital for troubleshooting and maintenance. The overall build quality and maintenance requirements should also be assessed to ensure durability and ease of use over time.

When considering the acquisition of a TPT wire bonder, budgeting and cost-formulation stand as pivotal factors that can significantly influence your choice. The first step in this process is assessing your operational requirements and the volume of production needed. Understanding whether you require a high-capacity machine or a more compact unit tailored for smaller projects will directly impact the budget. Additionally, factors such as the complexity of the bonding processes required can also alter the total cost, particularly if advanced functionalities are necessary.

Once you've established your basic requirements, it’s essential to evaluate the total cost of ownership for different models. This includes not only the initial purchase price but also maintenance costs, training expenses for staff, and potential downtime that may arise during the learning curve or equipment upgrades. It's wise to factor in future scalability—whether the machine will meet your needs as your production demands grow—this foresight can prevent unexpected financial burdens down the line. Prioritizing a balance between cost and capabilities can lead to a more informed and sustainable investment in your wire bonding needs.