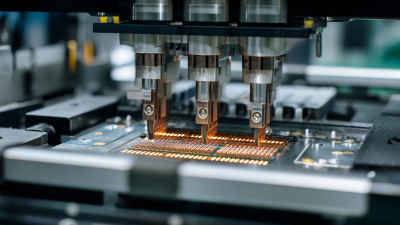

In the world of semiconductor manufacturing, the “Die Pick Up and Place” technology stands as a critical innovation. Dr. Lisa Chen, an expert in automation at XYZ Technologies, emphasizes its importance: "This technology revolutionizes efficiency in chip production." The ability to precisely pick and place dice enhances speed and accuracy, contributing significantly to production lines.

However, the use of Die Pick Up and Place technology is not without challenges. While it increases throughput, inconsistencies can arise if not properly calibrated. Small errors in placement can lead to significant issues down the line. Thus, the technology demands careful monitoring and constant optimization to truly harness its benefits.

As industries evolve, the expectation is not just for speed but also for reliability. Many companies still grapple with integrating new systems seamlessly. This reflection highlights the necessity of continuous improvement in Die Pick Up and Place processes. The balance between innovation and precision remains a pivotal focus in achieving optimal results.

Die pick up and place technology has revolutionized manufacturing processes. This method improves precision in handling delicate components. It ensures that every piece is placed exactly where it needs to go. This accuracy reduces errors significantly, but not without room for improvement. Sometimes, even the best systems face glitches that can lead to misplacements.

The automation of this technology saves time and labor costs. Operators can focus on more critical tasks instead of repetitive actions. However, the reliance on machines can lead to challenges. There are instances when the sensors fail, requiring manual intervention. This interruption can slow down production lines and cause frustration among workers.

Another major benefit is enhanced quality control. The technology allows for real-time monitoring during the placement process. It catches defects early, reducing waste. Yet, the potential for system overload exists. With high volume production, machines may struggle to keep pace, leading to bottlenecks. This highlights the need for constant evaluation and improvement in processes.

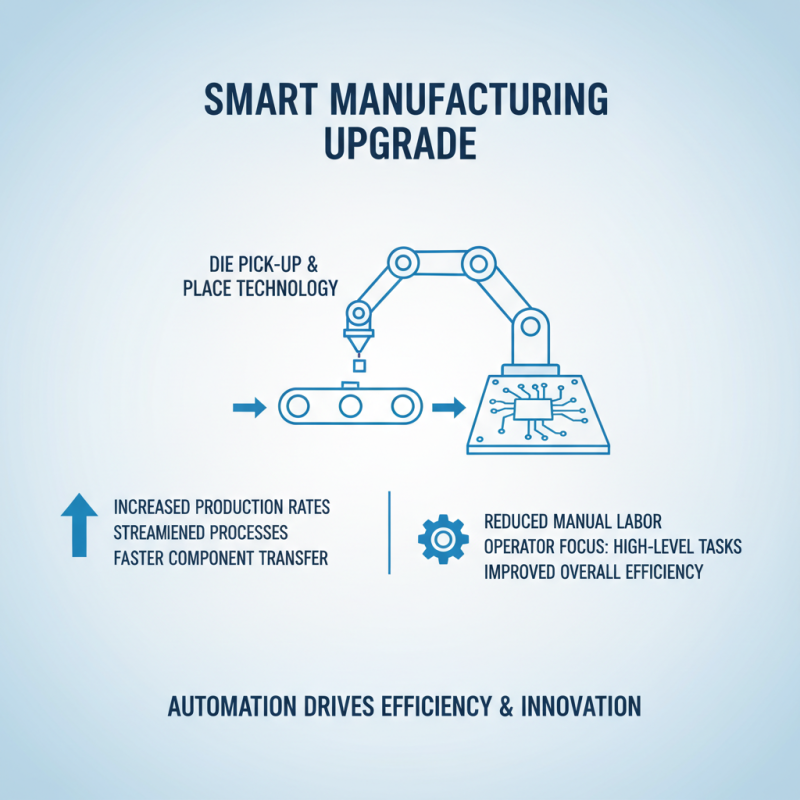

The integration of die pick up and place technology significantly boosts production rates in manufacturing. This automation streamlines processes, reducing the reliance on manual labor. For instance, machines can transfer components quickly, minimizing the time spent on each task. Operators can focus on higher-level responsibilities, leading to improved efficiency.

While automation enhances throughput, it also poses challenges. Workers may find themselves needing to adapt to new technologies. Training may not be straightforward. Skill gaps could emerge, as some operators struggle with advanced systems. Companies must invest time in ensuring employees are comfortable with these changes.

Another aspect to consider is maintenance. Automated systems can experience breakdowns, leading to unexpected downtime. This can disrupt production schedules. Regular assessments and a proactive approach are essential to mitigate these risks. There is a balance between efficiency and preparedness that organizations must navigate. Adopting this technology requires careful consideration of these factors.

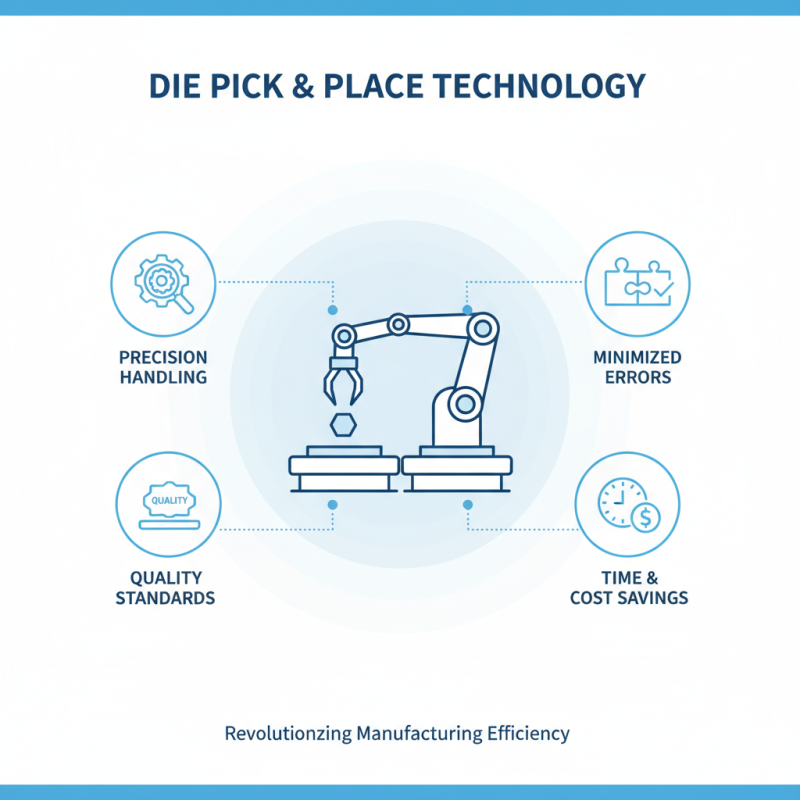

Die Pick Up and Place Technology is revolutionizing how industries handle components. This technology ensures precision handling during the manufacturing process. The careful gripping and placing of parts minimizes the chances of errors. Goods are more likely to meet strict quality standards. With fewer defects, companies can save both time and resources.

Enhanced quality control can be a game changer for many businesses. However, not every system is perfect. Occasionally, equipment may misplace items due to calibration issues. Workers must remain vigilant to catch any inconsistencies. These moments serve as reminders of the challenges that still exist despite technological advancements. Even with high precision, the human element remains crucial in maintaining quality.

Companies benefit immensely from adopting this technology. Yet, there’s always room for improvement. Regular maintenance and assessments are necessary. In any system, errors can creep in, leading to unnecessary waste. Reflecting on these shortcomings helps refine processes and achieve greater precision. The pursuit of excellence is continuous and requires ongoing effort.

Die pick up and place technology presents meaningful cost efficiency for various industries. Automation leads to long-term savings that can be significant. According to a recent industry report, companies adopting automation can cut labor costs by up to 30%. This reduction allows businesses to reallocate resources to other crucial areas. Over five years, the return on investment from automation can often exceed 200%.

However, businesses must weigh initial investments. The upfront costs can be substantial. Some reports indicate that 60% of smaller firms hesitate due to these expenses. Yet, the ongoing savings on labor and improved efficiency quickly balance this out. For example, reducing errors in the assembly line not only lowers material waste but also enhances overall productivity. Small errors can snowball, leading to costly recalls.

Moreover, the technology can adapt over time. Flexibility in operations is essential. As the market shifts, so do production needs. Companies using this technology reported a 25% faster response to market changes. This adaptability may be overlooked when evaluating benefits. Each organization must reflect on their unique needs and potential drawbacks. Balancing cost against these factors is not always straightforward.

Flexible production is crucial in today’s manufacturing landscape. Die pick up and place technology offers this flexibility by adapting to various die sizes and designs. Machines equipped with this technology can easily switch between different projects. This is particularly useful when a company needs to produce short runs of specialized items.

However, flexibility comes with challenges. The setup may require adjustments, which can lead to downtime. Workers must be trained to handle various die configurations, adding complexity. Sometimes, issues arise with the alignment or gripping of the dies. These hurdles can disrupt the workflow and affect productivity.

Despite these challenges, the benefits are clear. Adapting to various designs allows for quicker responses to market demands. Companies can experiment with innovative products without committing to long production cycles. This approach sparks creativity but requires a balance with reliability. Balancing these elements is essential for successful implementation.

Die Pick Up and Place technology has revolutionized the manufacturing industry by offering numerous benefits that enhance production efficiency and quality. One of the primary advantages is increased throughput; automation in handling processes significantly boosts production rates, allowing manufacturers to meet higher demand. Precision handling is another crucial benefit, as this technology reduces defects and improves quality control, ensuring that products meet stringent standards.

Furthermore, Die Pick Up and Place technology leads to cost efficiency by analyzing long-term savings associated with automation investments. Its flexibility in production accommodates various die sizes and designs, making it an adaptable solution for diverse manufacturing challenges. Lastly, safety improvements are a vital aspect, as automation minimizes workplace hazards, creating a safer environment for workers. Overall, implementing Die Pick Up and Place technology stands to transform manufacturing processes positively, leading to greater operational success.