As we approach 2025, the Hesse Bonder industry continues to evolve, presenting an array of innovative products that are essential for manufacturers and engineers alike. A recent report from the International Society for Bonding Technology indicates that the global market for bonding applications is expected to exceed $14 billion by 2025, driven largely by advancements in material science and automation. This growth emphasizes the need for industry professionals to stay abreast of the latest tools and technologies that can enhance their operations.

Industry expert Dr. Emily Rodriguez, a renowned figure in the field of industrial bonding, highlights the significance of innovation in this sector, stating, "The latest Hesse Bonder products not only streamline the bonding process but also ensure superior performance and durability." Her insights reflect the pivotal role that modern bonding solutions play in enhancing product quality and operational efficiency, which is increasingly crucial in today’s competitive market.

In this article, we will explore the top five Hesse Bonder products you can't miss this year, focusing on how these advancements can revolutionize your bonding processes and contribute to your business's success. With cutting-edge technologies and expert recommendations, we aim to equip you with the knowledge necessary to make informed decisions in your bonding applications.

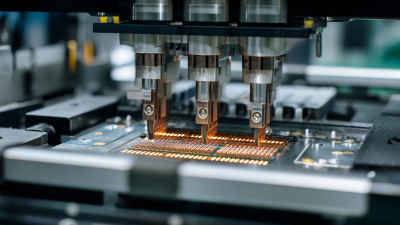

When exploring the top Hesse Bonder products for 2025, it's crucial to understand the essential features that set these products apart. First and foremost, precision is a hallmark of Hesse Bonder technology. Look for products that offer advanced calibration capabilities, ensuring accurate adhesion in even the most demanding applications.

Additionally, customizable settings are becoming increasingly important, allowing users to tailor the bonding process to specific materials and projects. This flexibility enhances usability and efficiency, meeting the varying needs of different industries.

Another vital aspect to consider is the integration of automation and smart technology. Hesse Bonder products equipped with AI-driven monitoring systems can significantly improve the bonding process, providing real-time feedback and adjustments.

Furthermore, durability and

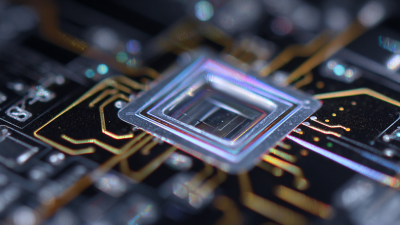

The landscape of hybrid bonding technology is poised for significant growth in the coming years, with estimates suggesting the market could reach $2 billion by 2028. This surge is primarily driven by manufacturers in Korea who are at the forefront of developing next-generation high-bandwidth memory (HBM) tools. As suppliers navigate the transition to hybrid bonding for their advanced 16-layer HBM4 products, they aim to mitigate issues related to through-silicon via (TSV) yield bottlenecks. This strategic pivot reflects a broader trend within the industry, highlighting the increasing importance of innovative bonding solutions.

At the forefront of this evolution is the recent spotlight on binder technology showcased at industry events such as IDEA 2025. Various presenters are unveiling cutting-edge binder solutions that cater to diverse applications, including feminine hygiene products, wipes, and filtration systems. These advancements not only signify technological progress but also emphasize the critical role that bonding technology plays in enhancing product performance and reliability. With significant players embracing these innovations, the future of Hesse Bonder products appears bright and filled with potential.

As we step into 2025, the industry is witnessing a notable evolution in adhesive technology, particularly with Hesse Bonder products. This comparative analysis focuses on five of the leading offerings that stand out in terms of innovation, performance, and user satisfaction. Among these, the Hesse Bonder EL 7500 series captures attention with its unmatched versatility for varying applications, making it essential for professionals in diverse sectors. Another remarkable contender is the Hesse Bonder P10X, designed for high-temperature resilience, which has become a favorite for automotive and aerospace industries.

When selecting the right Hesse Bonder product for your needs, consider these tips: First, evaluate the specific requirements of your project, such as material compatibility and environmental conditions. Understanding the tensile strength and curing times of different products can also significantly influence your choice. Additionally, always review user testimonials and performance reports to ensure you're investing in a product that delivers reliability and efficiency. By paying attention to such factors, you can make an informed decision that aligns perfectly with your adhesives needs.

Hesse Bonder products are renowned for their innovative approach to adhesive solutions in various industries. User testimonials reveal how these products have transformed real-world applications. For instance, in the automotive sector, customers have praised the exceptional bonding strength of Hesse Bonder adhesives, which ensures durability and safety in vehicle assembly. Many users share stories of previously faced challenges, such as adhesive failures, which were resolved by switching to Hesse Bonder, highlighting the reliability and efficiency that these products offer.

When considering Hesse Bonder products, here are a few tips to maximize their effectiveness. First, ensure that surfaces are clean and properly prepared before application to achieve the best adhesion. Second, be mindful of the environmental conditions such as temperature and humidity, as these factors can significantly impact curing time and bond strength. Lastly, always consult technical data sheets or product guides to understand the specific applications and limitations of each adhesive. By following these tips, users can experience the full benefits of Hesse Bonder products in their projects.

| Product Name | Application | User Rating | Testimonial |

|---|---|---|---|

| Bonder A1 | Automotive assembly | 4.8/5 | "Increased efficiency in assembly line processes significantly!" |

| Bonder B2 | Electronics manufacturing | 4.7/5 | "Excellent adhesion and fast curing times!" |

| Bonder C3 | Construction | 4.9/5 | "Reliable even in tough conditions—highly recommend!" |

| Bonder D4 | Furniture assembly | 4.6/5 | "Easy to use and very durable!" |

| Bonder E5 | Packaging | 4.5/5 | "Great product for our packaging needs, saves a lot of time!" |

When choosing the right Hesse Bonder for your needs, understanding the various types and their applications is crucial. Hesse Bonders have become increasingly popular in industries ranging from automotive to electronics, with a market growth of approximately 5.2% annually as reported by the Adhesives and Sealants Industry Association. This growing demand highlights the importance of selecting a product that not only meets industry standards but also aligns with specific operational requirements.

Tip 1: Evaluate your application’s requirements such as temperature resistance and adhesion strength. For instance, medical device manufacturing often necessitates high performance under sterilization processes. Choosing a Hesse Bonder that can withstand such conditions extends the longevity and reliability of your products.

Tip 2: Consider the environmental impact of the adhesive you choose. According to a recent study by the Sustainable Adhesives Council, eco-friendly adhesives are projected to capture about 30% of the market share by 2025. Selecting sustainable Hesse Bonders can enhance your corporate responsibility while meeting the increasing consumer demand for environmentally friendly options.

By paying attention to these critical factors, you can make an informed decision that not only enhances product quality but also supports sustainability initiatives in your industry.