In the manufacturing industry, the importance of choosing the right Die Pick Up Tools and Collets cannot be overstated. According to a recent report by Actionable Intelligence, improper tool selection can lead to inefficiencies affecting up to 30% of production time, ultimately impacting a company’s bottom line. Furthermore, research from the Manufacturing Institute reveals that nearly 70% of operational failures are attributed to inadequate tool management, highlighting the critical nature of making informed choices. As industries increasingly rely on precision and efficiency, understanding the intricacies of Die Pick Up Tools and Collets becomes essential for ensuring optimal performance and reducing downtime. This ultimate guide will provide you with five essential tips to make well-informed decisions, leveraging insights from industry experts to enhance your manufacturing processes.

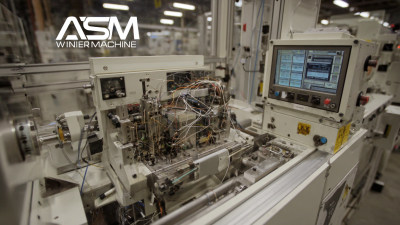

When selecting die pick up tools, it’s crucial to understand the various types available to ensure efficiency and precision in manufacturing processes. Die pick up tools, essential for handling and transferring dies in machining, come in several forms, including mechanical, magnetic, and vacuum-based systems. According to a report by Technavio, the global market for die pick up tools is projected to grow by 6% annually through 2025, highlighting the increasing demand for advanced tools that enhance productivity.

Mechanical die pick up tools, often favored for their simplicity and robustness, are ideal for larger dies, while magnetic versions excel in securely holding lightweight tools or parts. Vacuum-based systems, on the other hand, are gaining traction for their ability to reduce the risk of damage to delicate components, making them a preferred choice in sectors like electronics manufacturing. A study from MarketWatch shows that the demand for vacuum pick up tools has seen a significant rise, with a 15% increase noted in the last year alone, driven by advancements in technology and materials. Understanding these options allows companies to make informed decisions that align with their operational needs and enhance overall productivity.

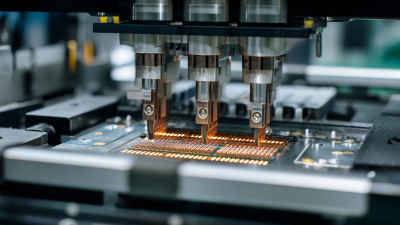

When selecting collets for your die pick up tools, the quality and features of these components can significantly impact your operational efficiency. One of the most critical aspects is the material used in the collet's construction. High-quality collets are typically made from hardened steel, which offers enhanced durability and resistance to wear. This ensures that they can withstand the repetitive motions and pressures of die pick up tasks, resulting in longer service life and lower maintenance costs.

Another key feature to consider is the clamping precision of the collets. A collet that provides a secure and stable grip on the tool is essential for accuracy during machining processes. Look for collets that boast tight tolerances and uniformity in design, as these factors contribute to minimizing vibrations and improving the overall performance of your tools. Additionally, consider the collet's compatibility with various tool sizes and shapes, as versatility can enhance your workflow and allow for smoother transitions between different operations. By focusing on these features, you can make an informed decision that enhances your die pick up capabilities.

When it comes to selecting die pick up tools and collets, compatibility with your equipment is paramount. Ensuring that the tools match your machine specifications can save time and enhance efficiency in production processes. According to a recent industry report, nearly 40% of tool-related downtime can be attributed to improper tool selection. This statistic underscores the importance of careful planning and evaluation in the tool selection process.

Tip 1: Verify the specifications. Always cross-reference the technical specifications of die pick up tools and collets with your equipment's requirements. This includes checking the size, taper, and material compatibility. A mismatch can not only delay production but lead to increased wear on your equipment.

Tip 2: Assess the application requirements. Different applications may require distinct tool features. For example, high-speed operations often necessitate collets that boast better precision and stability. Understanding the nuances of your application will guide you in choosing the most effective tools, ultimately influencing the success of your operations.

| Tip Number | Tip Description | Key Considerations | Recommended Tools |

|---|---|---|---|

| 1 | Assess compatibility with your equipment | Check specifications and requirements | Collet sets suitable for specific machines |

| 2 | Evaluate the size and shape of the dies | Ensure proper fit and function | Universal die pickup tools |

| 3 | Check the materials used in the tools | Select durable, high-quality options | Stainless steel and tool steel options |

| 4 | Consider the weight and handling of the tools | Choose tools that are easy to maneuver | Lightweight aluminum pickups |

| 5 | Review user feedback and ratings | Gain insights on performance and reliability | Customer-reviewed tools and accessories |

When it comes to selecting die pick up tools and collets, the balance between cost and quality is crucial for any craftsman. Investing wisely means looking beyond the sticker price to consider the long-term benefits of high-quality tools. While it may be tempting to choose the more affordable options, the durability and performance of premium tools often justify the investment. High-quality die pick up tools can enhance precision and efficiency, leading to faster job completion and reduced material waste.

As seen in recent evaluations of rotary tools, the market offers a range of products—both plug-in and battery-operated—that vary significantly in price and performance. Before making a decision, it's essential to assess what you need from these tools. Spending a little more upfront on a robust design can save you money over time, as quality tools will require less frequent replacement and provide better results. Prioritizing quality helps eliminate issues that are commonly associated with cheaper tools, such as lack of reliability or inadequate performance in demanding applications.

Maintaining die pick up tools and collets is crucial for ensuring their longevity and performance. One of the most effective ways to extend their lifespan is through regular cleaning. After each use, thoroughly clean the tools to remove any debris, chips, or residues. This will prevent corrosion and wear, which can significantly impact their effectiveness. Using a soft brush and a mild solvent can help maintain the integrity of the tools without causing damage.

Another essential aspect of maintenance involves proper lubrication. Applying the right lubricant can reduce friction between moving parts, which, in turn, minimizes wear and tear. Be sure to use lubricants that are suitable for the specific materials of your tools and collets. Additionally, routine inspections are necessary to identify any signs of damage or wear before they become significant issues. By addressing any potential problems promptly, you can avoid costly repairs or replacements in the future, guaranteeing the efficient operation of your die pick up tools and collets.