In the rapidly evolving landscape of semiconductor manufacturing, selecting the right wire bonders has become a critical decision for global buyers aiming to optimize production efficiency and product reliability. According to a recent report by MarketsandMarkets, the global wire bond equipment market is expected to grow from $500 million in 2021 to over $750 million by 2026, driven by increasing demand for advanced packaging technologies in electronics. As wire bonders play a pivotal role in ensuring the robustness of interconnections in integrated circuits, understanding their various types, specifications, and applications is essential. This comprehensive guide aims to equip buyers with the knowledge needed to make informed decisions when investing in wire bonders, ultimately enhancing their production capabilities and competitiveness in the marketplace.

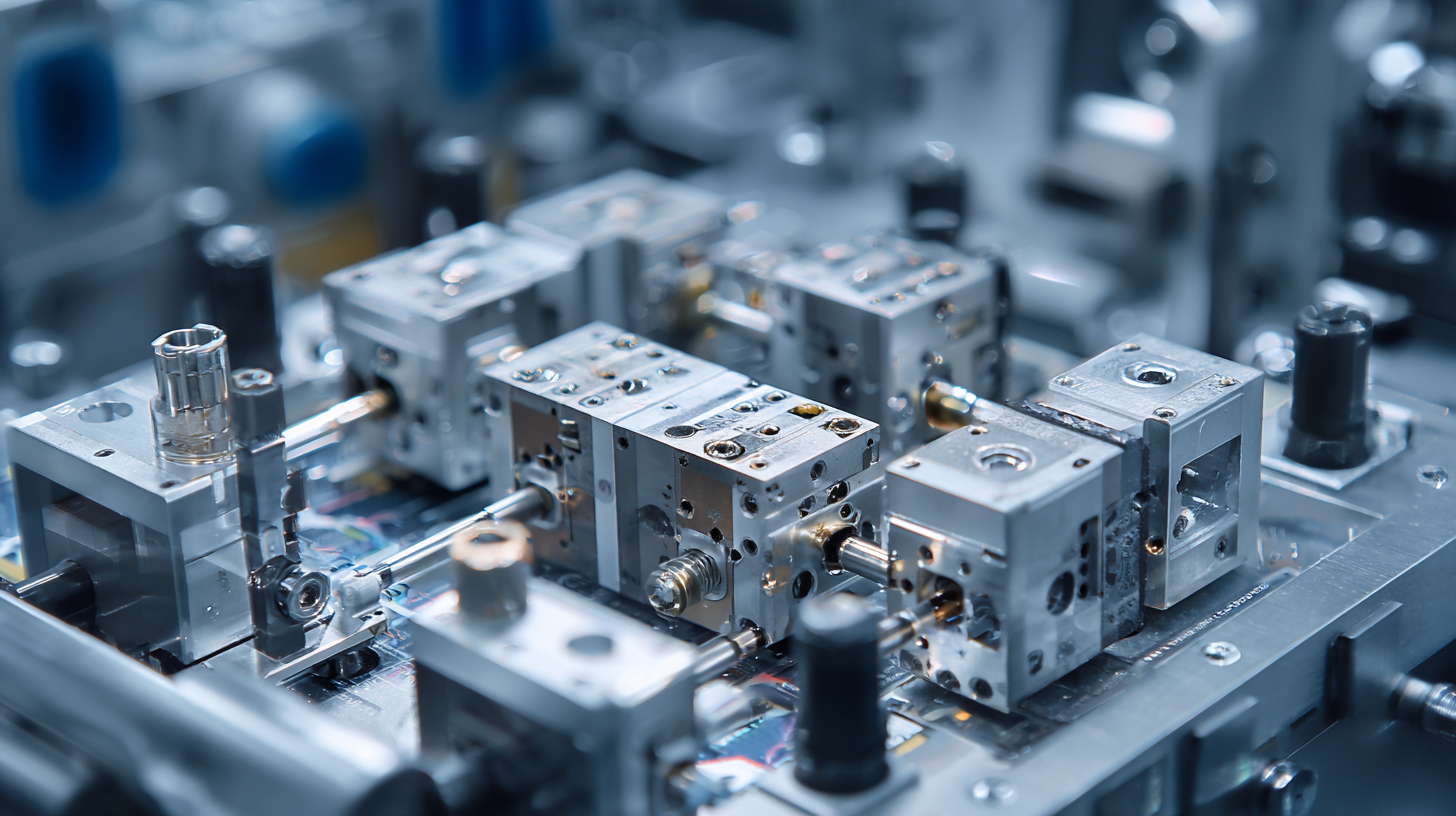

Wire bonding technologies have become a crucial aspect of modern electronics, particularly in semiconductor packaging and connectivity. With the global market for wire bonding poised for significant growth, it’s essential for buyers to understand the key types of wire bonding techniques available. Various methods such as ball bonding, wedge bonding, and ribbon bonding cater to different applications and materials, each offering unique benefits and limitations. Ball bonding, for example, is predominantly used in applications requiring high reliability and is optimal for thermocompression and ultrasonic bonding processes.

Moreover, the expanding applications of fine coaxial cables in industries such as telecommunications and broadcasting illustrate the versatility and demand for advanced bonding techniques. The trend towards increased automation and the adoption of technologies like the X-by-wire chassis in autonomous vehicles further drives the need for efficient and reliable wire bonding solutions. Understanding these technologies and their applications enables global buyers to make informed decisions that align with industry trends and technological advancements. As the market grows, staying updated on innovations in wire bonding technology will be essential for maintaining competitive advantages.

The wire bonding industry is witnessing significant growth, driven by advancements in technology and increasing applications across various sectors. The market size for wire bonding is projected to expand from $9.6784 billion in 2018 to an impressive $21.2607 billion by 2032, reflecting a compound annual growth rate (CAGR) of 5.4% during the forecast period. This trend highlights an escalating demand for efficient and reliable wire bonding solutions, strategically positioning companies to adapt to changing market dynamics.

With the rise in automation and the integration of sophisticated bonding techniques, such as laser bonding, the industry is evolving rapidly. Laser bonding technology is anticipated to play a critical role, with its application extending to various modes including conduction and deep penetration. The demand for laser welding equipment is also on the rise, with the global welding equipment market projected to grow at a CAGR of 6.3%, emphasizing the need for innovative solutions that cater to diverse welding requirements. As global buyers seek the best wire bonders, they must stay abreast of these market trends and technological advancements to make informed purchasing decisions and capitalize on future opportunities.

| Parameter | Value | Trends | Growth Projections (CAGR %) |

|---|---|---|---|

| Market Size (USD million) | 1,200 | Increase in demand for advanced packaging solutions | 5.2% |

| Key Applications | Automotive, Consumer Electronics, Telecommunications | Growth in EV and IoT sectors | 6.0% |

| Regional Market Share | Asia-Pacific (40%), North America (25%), Europe (20%) | Increasing manufacturing in Asia | 4.8% |

| Emerging Technologies | Ultrasonic Wire Bonding, Thermosonic Bonding | Shift towards microelectronics | 6.5% |

| Regulatory Trends | Environmental Regulations | Emphasis on sustainable manufacturing practices | 5.0% |

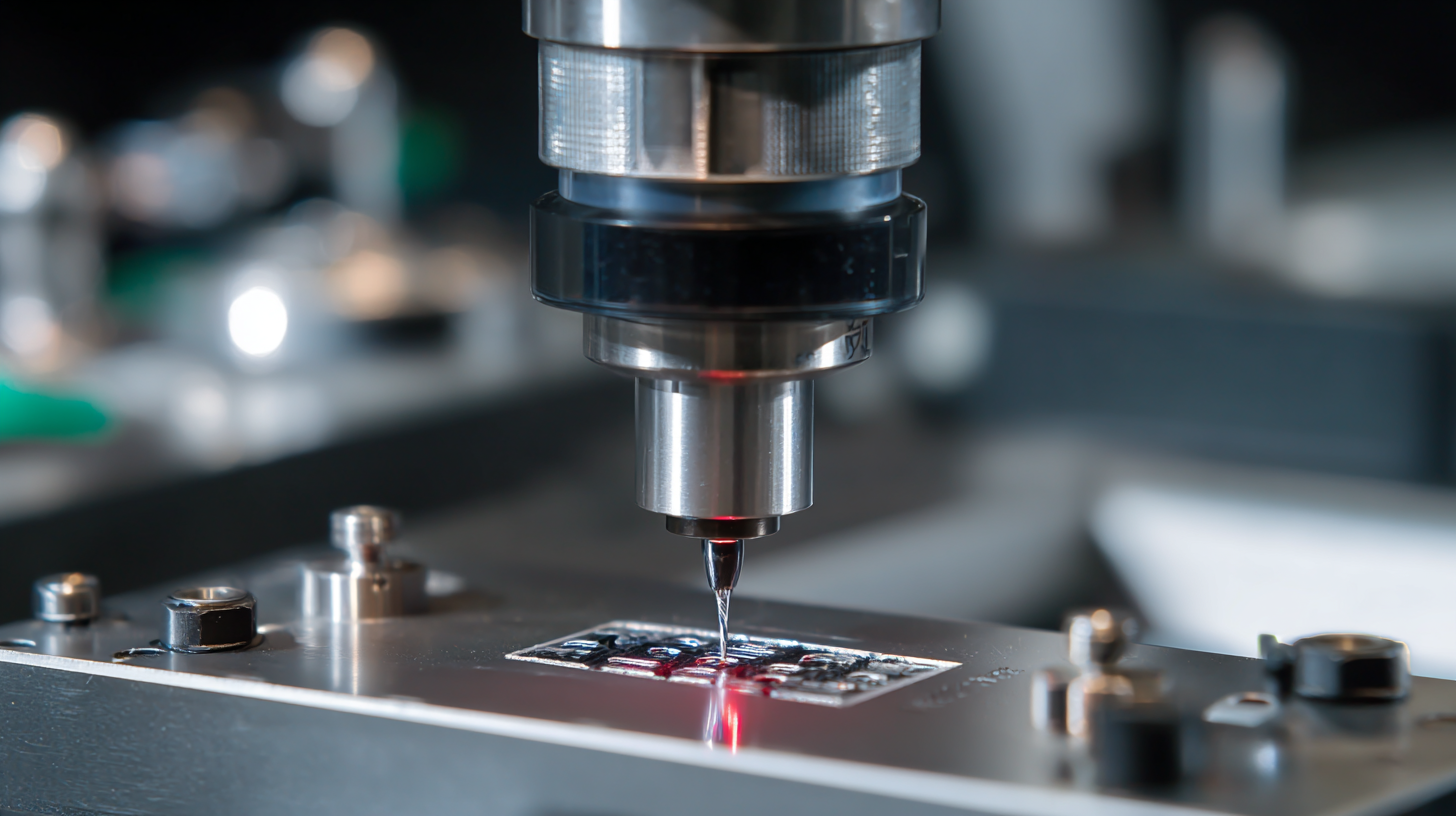

When selecting wire bonders, assessing their efficiency through performance metrics is paramount for optimal operational success. One of the key metrics to evaluate is the cycle time, which significantly affects production throughput. According to a recent report by the Semiconductor Equipment and Materials International (SEMI), advanced wire bonders are achieving cycle times as low as 0.3 seconds per bond, resulting in an increased overall throughput of up to 30% compared to traditional models. This efficiency can lead to substantial cost savings and higher output in high-volume production environments.

Another critical performance metric is bond strength, which directly correlates with the reliability of the final product. Industry studies indicate that bond strength should exceed 20 grams for a secure connection under stress conditions, ensuring minimal failure rates in end-use applications. Additionally, modern wire bonders utilize sophisticated algorithms to monitor real-time feedback, enhancing the process control and consistency of bond quality. According to Frost & Sullivan, manufacturers leveraging these technologies can reduce their defect rates by as much as 40%, making these advancements crucial for ensuring product integrity and competitiveness in the global market.

When selecting wire bonders, one critical factor to consider is the cost analysis, which requires balancing quality and price effectively. The latest advancements in hybrid bonding processes have transformed how manufacturers approach their production. Buyers must evaluate the capabilities of various wire bonders, considering not only the initial investment but also the long-term operational costs and potential savings from increased efficiency.

Tip: Always request a comprehensive demonstration of the equipment to assess its quality in real-time production scenarios. This allows you to understand better how performance aligns with your budget and production needs.

Furthermore, evaluate the support services and available training from vendors. A cheaper option might lead to higher costs down the line if support is lacking or if your team requires extensive training. Choosing a vendor that offers robust post-purchase support can enhance overall value and ensure your operations run smoothly.

Tip: Compare total cost of ownership, which includes maintenance, supplies, and potential downtime, alongside sticker price. This holistic view will help you identify the most cost-effective and reliable wire bonder for your specific applications.

The wire bonding industry is undergoing significant transformations driven by emerging technologies and innovative advancements. As new fabrication techniques and materials evolve, the demand for sophisticated wire bonding solutions is anticipated to rise. A recent market research report indicates that the global welding equipment market is expected to maintain a growth rate of 4% to 6% annually over the next few years, highlighting the increasing relevance of advanced wire bonding processes in semiconductor packaging.

As companies focus on enhancing their wire bonding capabilities, integration with revolutionary technologies becomes crucial. For instance, the shift towards automation and smart manufacturing in the semiconductor sector offers an opportunity for innovations in wire bonding equipment, aimed at increasing efficiency and precision. Reports suggest that the market for packaging equipment, particularly in power semiconductors, is on the upswing, driven by the surge in demand for high-performance devices across multiple sectors, including automotive and renewable energy. This paradigm shift not only enhances productivity but also contributes to the overall modernization of the semiconductor fabrication landscape.