In the rapidly evolving semiconductor industry, maximizing efficiency in manufacturing processes is paramount. With the global semiconductor market projected to reach over $600 billion by 2025, advancements in equipment such as the Wire Bonder Machine play a crucial role in enhancing production capabilities. According to a report by MarketsandMarkets, the demand for wire bonding technology is expected to grow significantly, driven by the increasing integration of advanced packaging solutions in various electronics applications. The Wire Bonder Machine, known for its precision and reliability in connecting semiconductor devices, offers manufacturers an opportunity to streamline their processes, reduce production costs, and improve yield rates. As competitive pressures intensify, adopting state-of-the-art wire bonding technologies is essential for companies aiming to sustain growth and achieve operational excellence in semiconductor manufacturing.

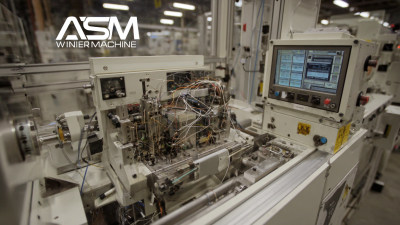

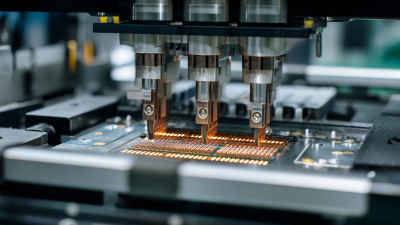

Advancements in wire bonding technology have significantly enhanced the efficiency and reliability of semiconductor manufacturing processes. Recent innovations in wire bonder machines have introduced features such as automated alignment systems and real-time feedback mechanisms. These enhancements enable precise bond formation, which is critical for the performance of semiconductor devices. The integration of advanced sensors and software algorithms allows for dynamic adjustments during the bonding process, reducing defects and improving yield rates.

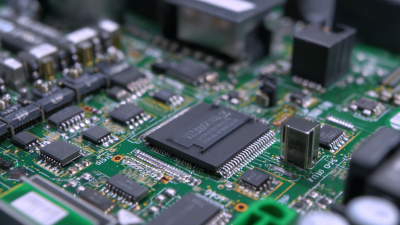

Moreover, the shift towards smaller and more complex semiconductor packages has necessitated the development of specialized wire bonding techniques. New materials, such as gold and aluminum alloys, provide better conductivity and mechanical strength, ensuring durability in various applications. Additionally, advanced techniques like thermocompression and ultrasonic bonding are becoming increasingly popular, offering superior bonding quality at reduced cycle times. As the semiconductor industry continues to demand higher throughput and lower costs, these technological advancements in wire bonder machines play a crucial role in meeting market needs while maintaining high standards of performance and reliability.

Modern wire bonder machines are pivotal in enhancing efficiency within semiconductor manufacturing. These machines have evolved significantly, incorporating advanced features that streamline production processes. For instance, the introduction of automated wire bonding systems has reduced cycle times by up to 30%, according to a report by the Semiconductor Equipment and Materials International (SEMI). This increase in speed allows manufacturers to keep up with the rising global demand for semiconductors, projected to reach a market value of $1 trillion by 2030, as highlighted by a recent McKinsey study.

Another key feature of contemporary wire bonders is their precision and adaptability. High-resolution cameras and advanced software algorithms enable real-time monitoring and adjustments, ensuring that each bond is made with impeccable accuracy. This capability minimizes defects and is vital in producing smaller, more complex semiconductor devices. The International Journal of Advanced Manufacturing Technology estimates that defects related to wire bonding can account for as much as 40% of failures in semiconductor devices. With modern machines that incorporate AI and machine learning, manufacturers can achieve bond quality rates exceeding 99%, drastically reducing waste and improving overall yield.

| Feature | Description | Importance in Manufacturing |

|---|---|---|

| High-Speed Bonding | Machines designed for rapid wire bonding to increase throughput. | Enhances production rates and efficiency of manufacturing processes. |

| Automated Alignment | Automatic alignment features to reduce manual setup and errors. | Minimizes labor costs and improves precision in bonding. |

| Flexible Configuration | Ability to adapt to various chip sizes and types. | Increases versatility in production lines to cater to different customer needs. |

| Real-Time Monitoring | Integrated systems for monitoring performance and quality during production. | Ensures consistent quality and allows for immediate corrections. |

| Environmentally Friendly | Machines designed to minimize waste and energy consumption. | Supports corporate sustainability goals and reduces operational costs. |

Automation has revolutionized the semiconductor manufacturing sector, particularly in wire bonding processes. Traditional wire bonding, which involved manual techniques, often resulted in inconsistencies and inefficiencies due to human error. With the advent of advanced wire bonder machines, the industry has embraced automation to improve accuracy and reduce cycle times. Automated machines utilize high-precision controls and sophisticated algorithms, ensuring that each bond is executed with utmost precision, thereby enhancing the overall yield of semiconductor devices.

Moreover, the impact of automation extends beyond just accuracy; it significantly boosts productivity. Automated wire bonders can operate continuously with minimal supervision, allowing manufacturers to optimize their production lines and reduce labor costs. As machines handle the repetitive tasks traditionally performed by humans, engineers can focus on more complex challenges, fostering innovation within the production process. This shift not only accelerates manufacturing timelines but also supports the development of more intricate and performant semiconductor applications, meeting the ever-evolving demands of the technology market.

The following chart illustrates the impact of automation on efficiency in semiconductor wire bonding processes. It compares manual operations versus automated systems over a three-year period.

The evolution of wire bonder machines has transformed semiconductor manufacturing, significantly enhancing efficiency and output. Traditional wire bonders, while effective, often face limitations in speed and precision, leading to bottlenecks in high-volume production environments. These machines rely on older technologies that may struggle with the demands of modern semiconductor devices, which require tighter tolerances and greater interconnect densities.

In contrast, advanced wire bonder machines incorporate cutting-edge features such as automated processes, improved bonding techniques, and real-time monitoring systems. These innovations not only streamline operations but also allow for greater adaptability to various materials and designs. The use of advanced algorithms facilitates quick adjustments to bond parameters, leading to fewer defects and reduced waste. As a result, manufacturers can achieve higher throughput and better overall yield, meeting the increasing demands for more complex semiconductor components while maintaining cost-effectiveness.

In the ever-evolving landscape of semiconductor manufacturing, advanced wire bonding techniques are becoming pivotal for enhancing production efficiency. The current projections suggest that the wire bonding equipment market will grow significantly, from an estimated $159.63 million in 2025 to $272.23 million by 2033, marking a robust compound annual growth rate of 6.9%. Such growth underscores the importance of innovation in manufacturing processes, highlighting that the future of wire bonding techniques will likely integrate smart automation and robotics to meet increasing demands.

As manufacturers grapple with challenges like labor shortages and supply chain disruptions, incorporating advanced wire bonder machines will be crucial for maintaining productivity. One promising development is the smart automotive wire binding technology, which recently received a patent. This innovation not only aims to revolutionize the welding process but also serves as a benchmark for the integration of intelligent automation in the manufacturing sector.

**Tip**: To stay ahead in the competitive semiconductor industry, consider investing in the latest technology, such as automated wire bonding machines, to streamline operations and enhance precision. Continuous training and upskilling of personnel on new machinery will also be essential to maximize efficiency and maintain quality standards.