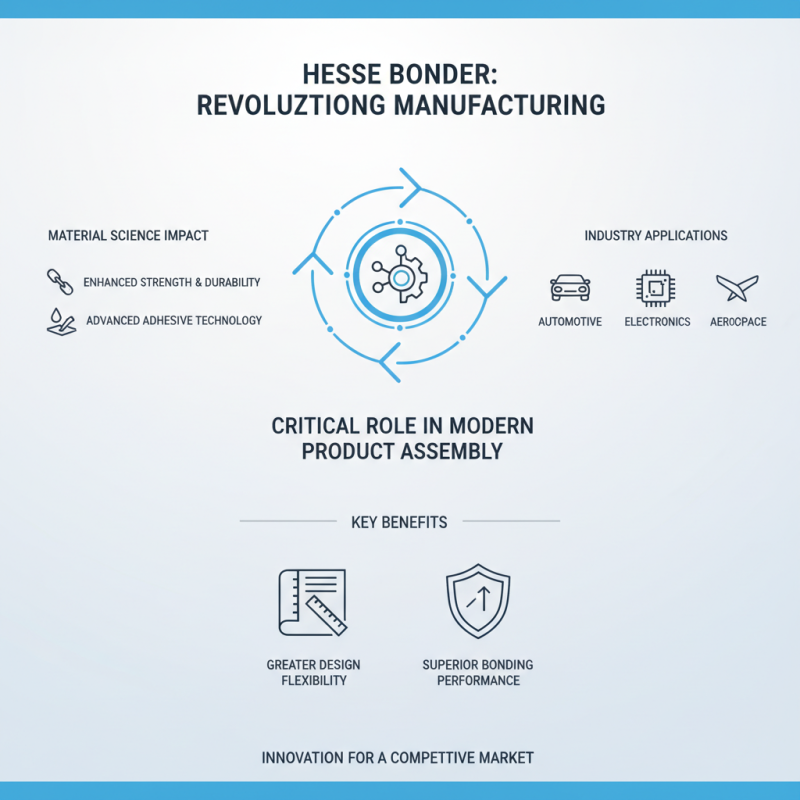

In modern manufacturing, efficiency is paramount. The Hesse Bonder emerges as a critical player in this domain. This innovative adhesive technology is vital in various industries, from automotive to electronics. A report by the Association for Manufacturing Technology indicates that advanced bonding solutions could reduce production costs by up to 30%.

Hesse Bonder offers unique features that enhance product longevity. Its bonding strength and reliability are unmatched. In the automotive sector, manufacturers reported a 15% increase in structural integrity using Hesse Bonder. However, challenges remain. Not all manufacturers are fully aware of its capabilities, which can limit adoption.

Furthermore, some may question the initial investment for implementing Hesse Bonder in their processes. While upfront costs might seem high, long-term savings highlight its value. Addressing this knowledge gap is essential for maximizing the benefits of Hesse Bonder. In an era where competition is fierce, manufacturers must embrace innovative solutions like this to thrive.

Hesse Bonder plays a critical role in modern manufacturing. Its impact on material science has been profound. This adhesive technology has revolutionized how products are assembled. Hesse Bonder enhances bonding strength and durability, making it a preferred choice for various applications. Moreover, it allows for greater design flexibility, which is vital in today's competitive market.

When considering Hesse Bonder, think about the properties it offers. For example, it provides excellent temperature resistance. This is crucial for products exposed to varying climates. Additionally, the ease of application can save time during production. Manufacturers benefit from reduced waste, making processes more efficient.

Tip: Always test bond strength before full-scale production. This ensures the adhesive meets your requirements. Organizations may overlook this, leading to costly errors. Remember that not every application is the same. Adjust your approach based on the specific materials involved. Each project may reveal new challenges that require reflection and adjustment.

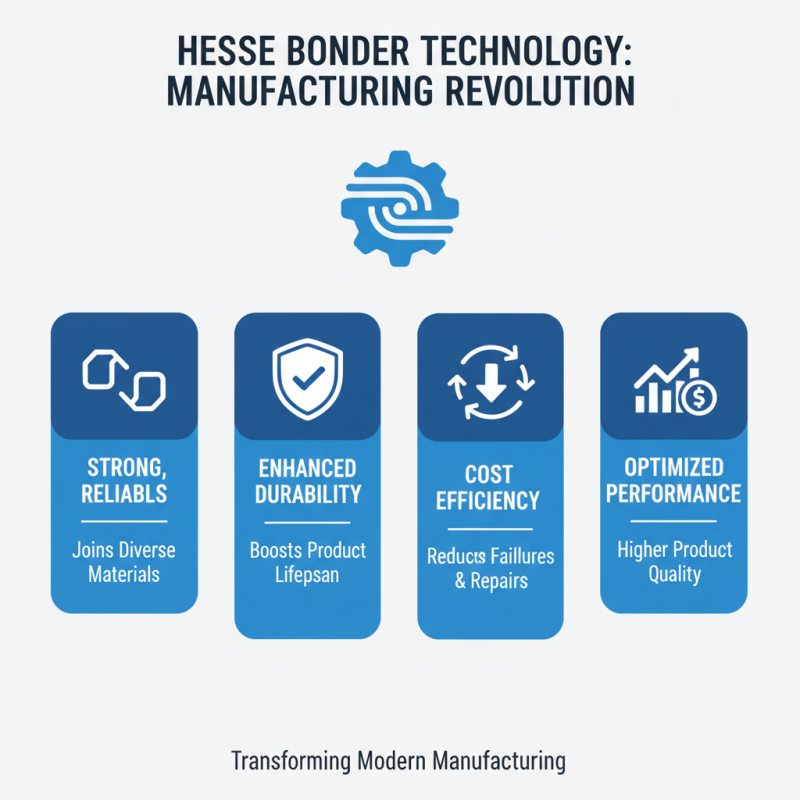

Hesse Bonder technology is transforming modern manufacturing. Its key feature lies in its ability to create strong, reliable bonds for various materials. This is crucial for durability and overall product performance. The efficiency of this technology reduces operational costs. Businesses benefit from fewer failures and repairs.

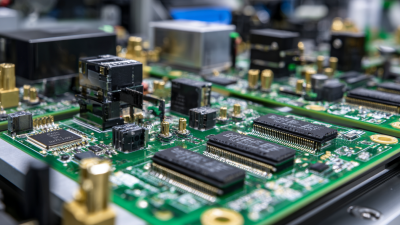

Another aspect is versatility. Hesse Bonder works well with metals, plastics, and composites. This variety meets diverse industry needs. However, using this technology requires precise control. Mistakes can lead to weak bonds, which compromise quality. Monitoring requires attention and training, which some companies may struggle with.

Additionally, this technology enhances production speed. Faster processes lead to higher output. Yet, rushing can invite errors. A balanced approach must be maintained to preserve quality. In manufacturing, the benefits are clear, but careful implementation is essential.

Hesse Bonder plays a significant role in various industries today. Its adhesive properties are remarkable. In the automotive field, for instance, it securely bonds components. This enhances vehicle durability and safety. Manufacturers appreciate its speed, which is crucial in a fast-paced environment.

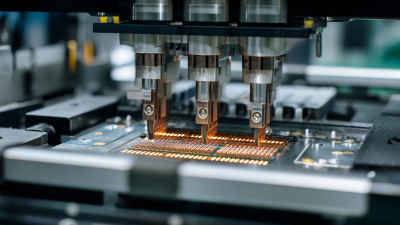

In electronics, using Hesse Bonder is common. It helps in assembling delicate parts like circuit boards. Precise application is vital here. A small error can disrupt connectivity. Yet, its consistency often impresses engineers. They rely on it for reliable performance.

Another interesting area is the medical device industry. Devices need strong, long-lasting bonds. Any weakness could compromise safety. Hesse Bonder meets these rigorous standards, yet some applications need deeper scrutiny. Companies must ensure compatibility with various materials. This demands more research and testing. It is essential to address gaps for better results.

Modern manufacturing requires efficiency and reliability. Hesse Bonder stands out in this landscape. Traditional bonding methods often involve lengthy processes. They typically rely on mechanical fasteners or adhesive that takes time to cure. This can slow down production lines significantly.

In contrast, Hesse Bonder offers faster curing times. It uses advanced technology to bond materials effectively and quickly. This innovation allows manufacturers to maintain a steady workflow. However, it's not entirely without flaws. The initial setup may require specific equipment and training. Some operators may be hesitant to change established practices due to uncertainty.

The adaptability of Hesse Bonder is notable. Its application in various industries proves beneficial. Yet, this versatility requires careful consideration of material compatibility. Not all materials react the same way with newer bonding agents. Some trials may lead to unexpected results. This unpredictability can disrupt the manufacturing process. Therefore, a thorough evaluation of each situation is essential.

In modern manufacturing, innovations in adhesive technologies are shaping the future. Hesse Bonder is at the forefront of these advancements. According to recent industry reports, the global adhesive market is projected to reach approximately $70 billion by 2026, growing at a CAGR of 4%. This growth highlights the increasing significance of high-performance adhesives in manufacturing processes.

With the rise of automation and smart manufacturing, Hesse Bonder’s innovations are critical. For instance, new formulations enhance speed and efficiency. These adhesives can cure faster and bond more effectively. In sectors like automotive and electronics, high-strength adhesives contribute to lighter, more efficient products. Yet, the challenge remains: ensuring sustainability alongside performance.

As manufacturers strive for greener practices, the need for eco-friendly adhesives is urgent. Companies must balance functionality with environmental impact. This reflection is vital, as industries cannot overlook the demand for sustainable solutions. Hesse Bonder technologies may be part of that equation, but continuous improvement is necessary. Embracing these innovations can lead to significant advancements, yet the path remains complex.

| Innovation Aspect | Description | Impact on Manufacturing | Future Trends |

|---|---|---|---|

| Advanced Adhesive Technologies | Innovative bonding solutions with enhanced strength and flexibility. | Improved product durability and performance. | Increased use in lightweight materials and composites. |

| Automated Application Processes | Integration of robotics for precise adhesive application. | Higher efficiency and reduced labor costs. | Expansion in fully automated manufacturing lines. |

| Sustainability Initiatives | Development of eco-friendly adhesive materials. | Reduction of environmental impact during production. | Growing demand for green manufacturing practices. |

| Smart Manufacturing Integration | IoT-enabled bonding systems for real-time monitoring. | Enhanced quality control and reduce waste. | Increased adoption of Industry 4.0 principles. |