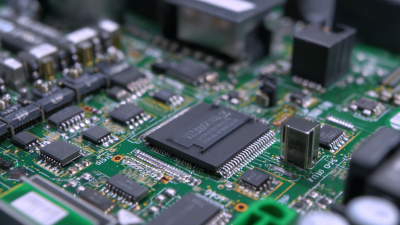

In the rapidly evolving semiconductor industry, the choice of bonding wire significantly impacts the performance and reliability of electronic devices. Heraeus Bonding Wire has solidified its position as an industry leader, thanks to its superior performance and innovative technology. According to a recent report by industry analysts, the global bonding wire market is projected to reach $3.06 billion by 2026, growing at a CAGR of 5.3%. Heraeus continues to dominate this market with its exceptional quality and a product portfolio that addresses various challenges, including wire diameter, oxidation resistance, and thermal stability. With advancements in semiconductor technology demanding increasingly precise and reliable connections, Heraeus Bonding Wire stands out for its ability to meet and exceed these evolving needs, ensuring optimal performance across diverse applications in the semiconductor sector.

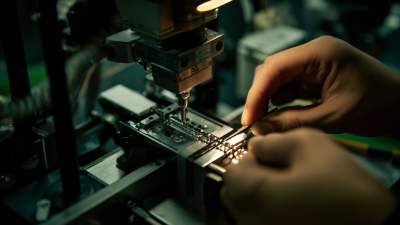

The unmatched quality of Heraeus bonding wire in semiconductor manufacturing sets it apart as an industry leader. Recently, Heraeus announced the opening of an innovative laboratory in Hsinchu, Taiwan, which marks its fifth global facility focused on semiconductor solutions. This strategic move enhances their capacity to develop cutting-edge materials that meet the rising demands of the semiconductor industry, especially in applications like memory and high-end smart cards.

One of the standout features of Heraeus bonding wire is its ability to adapt to emerging technologies, such as 5G. The introduction of innovative products like AgCoat Prime, a gold-silver alloy wire, showcases their commitment to providing sustainable and efficient alternatives to traditional gold wire. This development not only aligns with industry trends but also addresses material shortages while maximizing production efficiency.

**Tips:** When selecting bonding wire for semiconductor applications, consider factors such as thermal properties, electrical conductivity, and environmental sustainability. Always stay informed about the latest innovations in materials to ensure you are using the best solutions for your production needs. Additionally, collaborating with research facilities can provide valuable insights into the future of semiconductor manufacturing.

This chart illustrates the perceived quality factors of bonding wire used in semiconductor manufacturing.

Heraeus bonding wire continues to lead the semiconductor market, driven by innovative technologies that enhance performance in this rapidly evolving industry. The semiconductor gold bonding wire market is projected to expand significantly, from 1.2 billion USD in 2024 to 2.5 billion USD by 2033, highlighting a strong demand for advanced materials that can meet increasing performance standards. This growth is bolstered by breakthroughs in thermal management strategies for power electronics, particularly in electric vehicles, where enhanced heat dissipation is crucial for reliability and efficiency.

At upcoming industry events, Heraeus is set to showcase its latest developments, including sustainable semiconductor materials, which underline the company’s commitment to innovation and environmental responsibility. Furthermore, the introduction of vertical wire bonding innovations demonstrates Heraeus's ability to adapt to market demands, particularly for fine-pitch memory packaging solutions. These advances are expected to drive the market further, with the gold bonding wire for semiconductor packaging anticipated to grow at a CAGR of 6.3% from 2025 to 2035. Such trends illustrate the pivotal role that Heraeus plays in shaping the future of semiconductor technologies.

Heraeus bonding wire stands out as a benchmark for reliability and consistency in semiconductor applications, drawing parallels to recent trends in the financial markets, where strong demand for bonds indicates a stable economic environment. Just as the resilience of certain bond funds has been noted, Heraeus bonding wire is engineered to deliver dependable performance over time, making it the preferred choice for manufacturers seeking to minimize risks and maximize product integrity. The consistent quality of Heraeus products ensures that semiconductor devices maintain their function and durability, reinforcing trust among its users.

In an industry where precision is paramount, the reliability of Heraeus bonding wire mirrors the confidence observed in robust financial instruments. Investors are often drawn to options that promise consistency, much like semiconductor manufacturers rely on the unmatched reliability provided by Heraeus. This commitment to excellence not only enhances production efficiency but also aligns with the industry's ever-growing demand for high-performance materials, solidifying Heraeus's position at the forefront of semiconductor technology.

In the competitive landscape of semiconductor manufacturing, cost-effectiveness remains a crucial factor for high-volume production. Heraeus Bonding Wire distinguishes itself not just through quality, but also by providing solutions that optimize production expenses. By leveraging advanced materials and innovative manufacturing processes, Heraeus has developed bonding wires that minimize waste and maximize efficiency, making them an ideal choice for semiconductor applications where margins are often tight.

Furthermore, Heraeus Bonding Wire is designed to ensure minimal downtime and reduced maintenance costs. With a focus on reliability, the products withstand the rigors of high-volume production while maintaining performance consistency. This translates to fewer production interruptions, allowing manufacturers to maintain throughput and manage costs effectively. As companies seek to enhance their operational efficiency, Heraeus solutions stand out as a smart investment in the semiconductor sector, reinforcing their position as an industry leader.

Heraeus bonding wire has established itself as a frontrunner in the semiconductor industry, thanks in large part to its commitment to sustainability and environmental responsibility. In a world where technology and ecological awareness often clash, Heraeus proves that innovation can go hand in hand with protecting our planet. The company invests heavily in eco-friendly manufacturing processes and sourcing materials that minimize environmental impact, ensuring that their bonding wires not only meet performance standards but also support a sustainable future.

When choosing bonding wires, manufacturers should consider the environmental certifications associated with the materials used. Opting for products that are compliant with international environmental standards can significantly reduce the ecological footprint of semiconductor production. Additionally, evaluating the lifecycle impact of the bonding wire can help in selecting options that promote resource efficiency and waste reduction.

Furthermore, Heraeus is committed to advancing recycling initiatives within the industry. By encouraging the recycling of materials used in semiconductor applications, Heraeus not only enhances sustainability but also fosters a circular economy. Companies looking to improve their environmental responsibility can leverage Heraeus' efforts to incorporate more recyclable components in their production processes, ultimately driving the industry towards a greener future.