Gold Wire Bonding is a crucial technique in the semiconductor industry, playing a pivotal role in establishing electrical connections between the chip and its packaging. This method not only influences the overall performance of semiconductor devices but also impacts their long-term reliability. As the demand for more efficient and powerful electronic devices continues to grow, understanding the nuances of Gold Wire Bonding becomes increasingly important. This exploration delves into how variations in Gold Wire Bonding processes and materials can significantly affect parameters such as thermal conductivity, mechanical strength, and susceptibility to environmental factors. By analyzing these impacts, we aim to provide insights into optimizing Gold Wire Bonding for enhanced semiconductor performance and reliability, ultimately contributing to the advancement of technology in various applications, from consumer electronics to industrial systems.

Gold Wire Bonding is a crucial technique in the semiconductor industry, playing a pivotal role in establishing electrical connections between the chip and its packaging. This method not only influences the overall performance of semiconductor devices but also impacts their long-term reliability. As the demand for more efficient and powerful electronic devices continues to grow, understanding the nuances of Gold Wire Bonding becomes increasingly important. This exploration delves into how variations in Gold Wire Bonding processes and materials can significantly affect parameters such as thermal conductivity, mechanical strength, and susceptibility to environmental factors. By analyzing these impacts, we aim to provide insights into optimizing Gold Wire Bonding for enhanced semiconductor performance and reliability, ultimately contributing to the advancement of technology in various applications, from consumer electronics to industrial systems.

The historical context of gold wire bonding in semiconductor technology reveals its pivotal role in the evolution of electronic devices. Introduced in the 1960s, gold wire bonding quickly became a preferred method for connecting chip and package in the semiconductor industry due to its excellent reliability and performance characteristics. According to a recent report by SEMICON (2022), gold wire bonding accounted for around 60% of all bonding applications in the semiconductor sector, highlighting its dominance in the field.

Over the decades, the use of gold wire bonds has persistently evolved, adapting to advancements in semiconductor manufacturing and materials science. The thermal and electrical conductivity of gold has proven advantageous, especially in high-frequency applications. A study by Yole Développement (2021) indicated that the bond yield of gold wire connections can reach up to 99.9%, which is a testament to the technological improvements associated with this bonding technique. The integration of gold wire bonding into flip-chip packages further solidified its importance, particularly in microelectronics and automotive semiconductor applications, where performance and reliability are paramount.

This chart illustrates the impact of gold wire bonding on various performance metrics in semiconductor technology, highlighting its advantages in thermal and electrical conductivity, as well as its reliability and cost considerations.

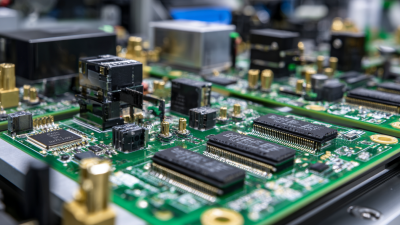

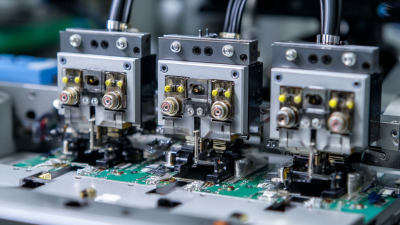

Gold wire bonding is a critical process in semiconductor manufacturing, playing a vital role in the electrical connection between the chip and its package. The mechanics of this technique involve the use of thin gold wires, typically ranging from 15 to 40 micrometers in diameter, which are thermosonically bonded to the bonding pads on the semiconductor die. The process requires precise control of parameters such as temperature, force, and ultrasonic energy to ensure that the wire maintains a strong and reliable connection while minimizing damage to the delicate semiconductor materials.

In addition to enhancing electrical connectivity, gold wire bonding significantly impacts the overall performance and reliability of semiconductor devices. The excellent conductivity and corrosion resistance of gold contribute to lower electrical resistance and improved thermal performance. However, the bonding technique must be carefully optimized to avoid issues like wire sweep and ball deformation, which can lead to increased failure rates. Understanding these mechanics is essential for engineers to develop robust bonding processes that can withstand the rigorous demands of modern electronic applications, ensuring that devices are not only efficient but also long-lasting.

| Parameter | Description | Impact on Performance | Impact on Reliability |

|---|---|---|---|

| Wire Diameter | Thickness of the gold wire used for bonding | Affects current carrying capacity | Larger diameter may improve mechanical strength |

| Bonding Temperature | Temperature at which bonding occurs | Higher temps can enhance bonding strength | Excessive heat can damage semiconductor materials |

| Bonding Time | Duration of the bonding process | Longer times improve bond quality | Risk of thermal-induced stress increases with time |

| Ultrasonic Power | Power level of ultrasonic energy used during bonding | Boosts bond hardness and stability | Excessive power can lead to material degradation |

| Environment | Physical conditions during the bonding process | Controlled environments reduce contaminants | Better environmental control leads to enhanced long-term reliability |

Gold wire bonding has long been a critical method for interconnecting semiconductor devices, playing a fundamental role in determining their electrical performance. The fine diameter of gold wires allows for effective signal transmission while minimizing parasitic inductance and capacitance. This enhanced connectivity is crucial in high-frequency applications where even minor deviations can result in significant performance deficits. Additionally, gold’s excellent conductivity ensures that the electrical paths maintain optimal operation under various conditions, leading to improved device efficiency.

Gold wire bonding has long been a critical method for interconnecting semiconductor devices, playing a fundamental role in determining their electrical performance. The fine diameter of gold wires allows for effective signal transmission while minimizing parasitic inductance and capacitance. This enhanced connectivity is crucial in high-frequency applications where even minor deviations can result in significant performance deficits. Additionally, gold’s excellent conductivity ensures that the electrical paths maintain optimal operation under various conditions, leading to improved device efficiency.

When considering gold wire bonding, it's essential to pay attention to the bonding process parameters. Proper control over temperature and pressure during bonding can significantly influence the integrity and reliability of the connections.

Tip: Always conduct thorough testing of the bonding process to ensure that the wire bonds are formed correctly and exhibit minimal resistance.

Furthermore, the choice of bonding technique—such as ball bonding versus wedge bonding—can affect the stress distribution within the semiconductor package, impacting long-term reliability. Therefore, selecting the appropriate method is vital for achieving the desired electrical performance while ensuring the durability of the semiconductor devices.

Tip: Regularly review the latest advancements in bonding technologies to make informed decisions that will enhance both performance and reliability.

Gold wire bonding has emerged as a critical process in enhancing the reliability and longevity of semiconductor devices. According to the International Roadmap for Devices and Systems (IRDS), gold wire bonding provides superior thermal and electrical conductivity, which is vital for efficient performance in advanced applications. This process demonstrates excellent fatigue resistance, making it suitable for demanding environments where devices are exposed to temperature fluctuations and mechanical stress. Recent studies show that gold wire bonds exhibit a failure rate significantly lower than that of other materials, with the failure rate for gold bonds estimated at less than 1% after 1,000 thermal cycles.

Furthermore, a report by the Semiconductor Research Corporation (SRC) highlights that gold wire bonded semiconductors retain optimal performance over extended periods, thus ensuring longer product lifespans. This longevity stems from gold's inert nature, which minimizes the risk of corrosion common in other bonding materials. The SRC also indicates that with proper bonding techniques, gold wire bonds can enhance the overall device reliability, leading to reductions in total lifecycle costs. Such findings underscore the importance of employing gold wire bonding to meet the increasing demands for reliability in semiconductor manufacturing.

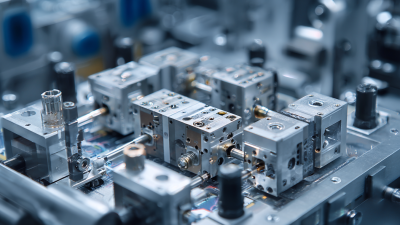

The landscape of gold wire bonding techniques is rapidly evolving, incorporating advanced approaches that improve semiconductor performance and reliability. Emerging innovations focus on enhancing the efficiency of the bonding process through the integration of automated equipment and sophisticated software. These technologies facilitate precision in wire placement and thermal management, leading to a reduction in defects and a significant increase in yield rates. As semiconductor devices become increasingly complex, the demand for high-performance bonding solutions is driving research into new gold alloys and bonding methods that can withstand harsher operating conditions.

Additionally, future trends in gold wire bonding are leaning towards sustainability and environmental responsibility. Companies are investing in research to recycle gold wire and explore alternative materials that can potentially reduce costs and environmental impact. Innovations such as ultra-thin wire bonding and novel encapsulation techniques are also being introduced, aimed at minimizing the size and improving the reliability of semiconductor packages. As the industry pushes towards miniaturization and greater performance, the ongoing advancements in gold wire bonding will play a critical role in enabling next-generation semiconductor technologies.