As we look ahead to the technological advancements shaping the future, the realm of Automatic Wire Bonder solutions stands at the forefront of innovation. These machines have revolutionized the microelectronics field, enabling seamless connections in semiconductor packaging through precise wire bonding techniques. However, as the industry evolves, there is a growing demand for alternatives that enhance efficiency, reduce costs, and improve reliability. This blog explores the innovative alternatives to traditional Automatic Wire Bonder systems, examining emerging technologies and trends that are poised to transform the way we approach wire bonding in 2025 and beyond. Join us on this journey as we delve into the possibilities and challenges that lie ahead, setting the stage for a new era in electronics manufacturing.

The automatic wire bonding market is poised for significant advancements by 2025, driven by a surge in demand for high-performance semiconductor devices. According to a report by MarketsandMarkets, the global wire bonding equipment market is projected to grow from USD 1.87 billion in 2020 to USD 2.45 billion by 2025, at a CAGR of 5.4%. This growth is fueled by innovations in bonding materials and technologies, such as the emergence of ultrasonic and thermosonic bonding methods that enhance the reliability and performance of wire bonded connections.

Additionally, the integration of artificial intelligence and machine learning into wire bonding systems is revolutionizing the industry. These technologies optimize bonding processes, improve yield rates, and reduce operational costs. A study by ResearchAndMarkets highlights that the AI-driven solutions can reduce the bonding cycle time by up to 30%, highlighting the increasing emphasis on efficiency and cost-effectiveness in the 2025 market landscape. As manufacturers continue to explore these innovative alternatives, the automatic wire bonder solutions of the future will focus on precision, speed, and adaptability, ultimately meeting the evolving requirements of the semiconductor industry.

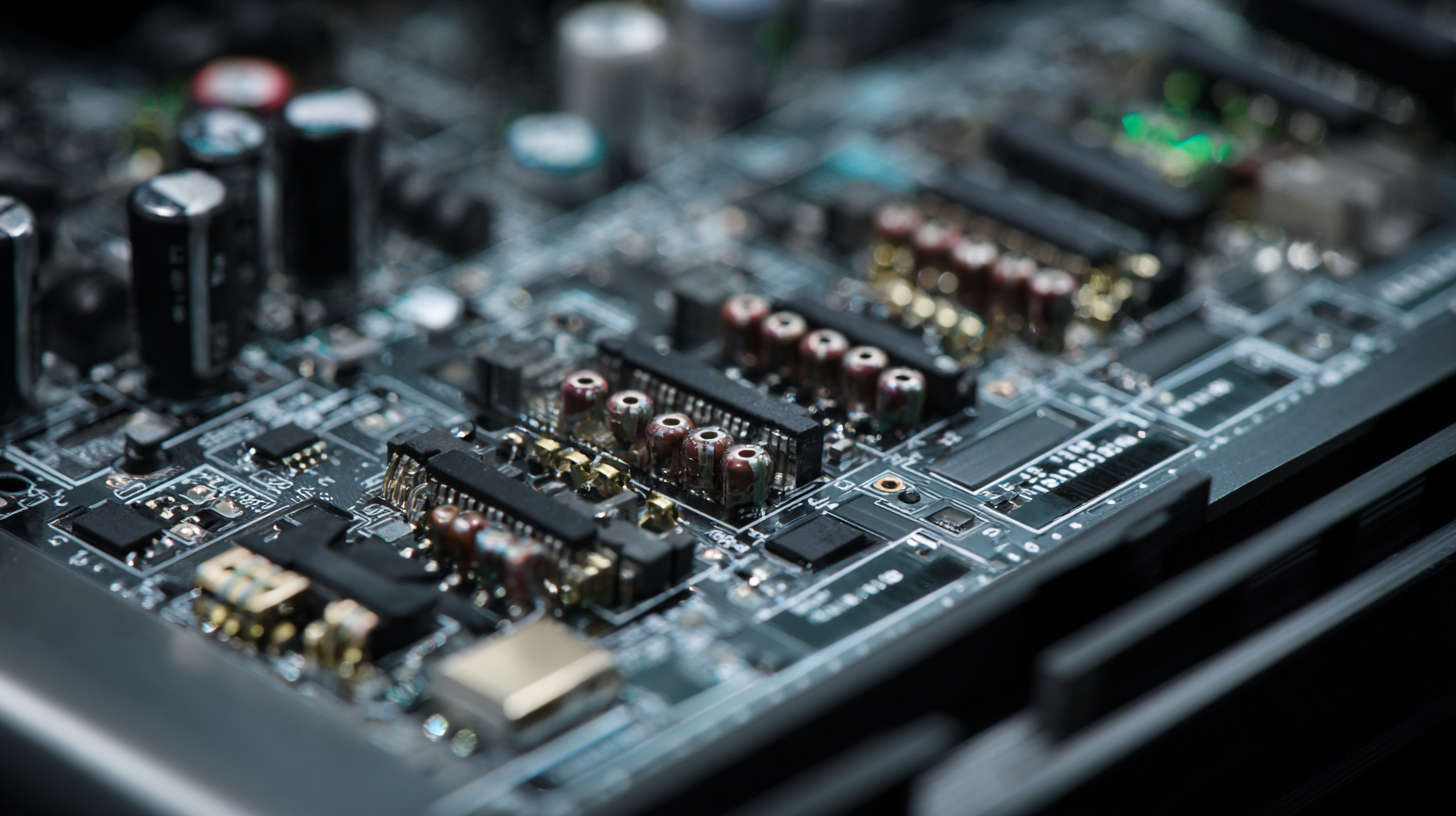

In the rapidly evolving field of semiconductor manufacturing, wire bonding is crucial for ensuring electrical connectivity in microelectronic devices. A comparative analysis of leading automatic wire bonder solutions reveals substantial variation in their unique features, each tailored to specific applications. For instance, K&S's 8020 is renowned for its versatility and precision, catering well to both gold and aluminum wire bonding. Meanwhile, the Hesse Mechatronics Alpha 500 stands out with its advanced laser technology, delivering enhanced speed and accuracy, which can significantly reduce cycle time by up to 30%, according to recent industry reports.

When selecting a wire bonder, it's crucial to consider factors such as bond type, production volume, and product lifecycle. Companies should conduct thorough assessments of their manufacturing needs to choose a solution that maximizes efficiency. **Tip:** Prioritize systems that allow easy program customization to adapt to different wire materials and bonding techniques, ensuring flexibility as your production demands change.

Additionally, the integration of Industry 4.0 capabilities in modern wire bonders presents an opportunity for continuous improvement in processes. Features like real-time monitoring and predictive maintenance not only enhance productivity but also minimize downtime. **Tip:** Invest in training for staff to leverage these advanced features effectively, optimizing the overall performance of your wire bonding solutions. This investment can lead to significant cost savings and improved quality in the long run.

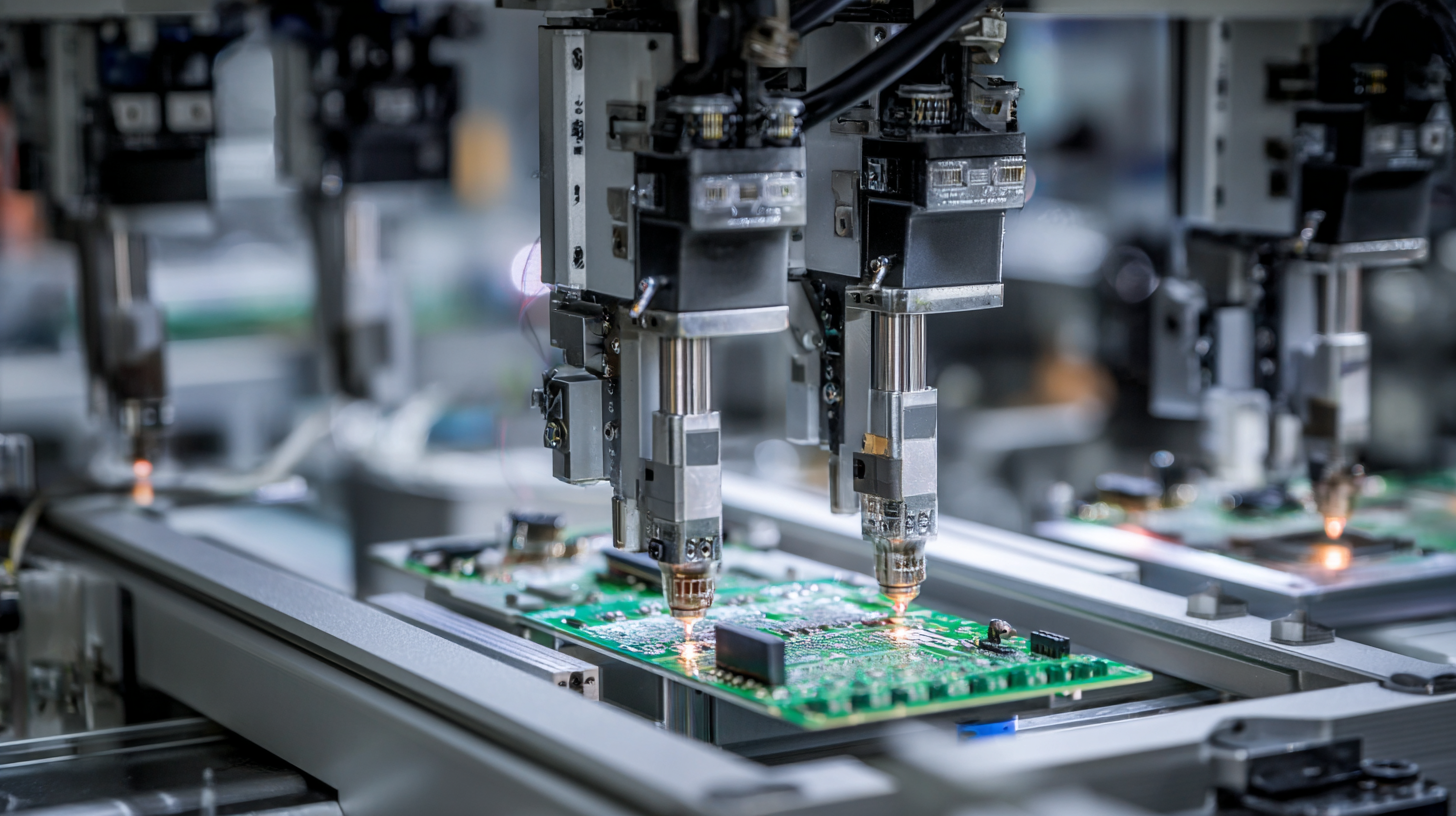

The landscape of wire bonding in electronics manufacturing is rapidly evolving, driven by emerging trends that seek to enhance efficiency and performance. One notable trend is the integration of automation and robotics into the wire bonding process. These technologies not only minimize human error but also streamline production, allowing manufacturers to keep pace with the growing demand for smaller and more complex electronic devices. By leveraging advanced algorithms and machine learning, automated wire bonders can optimize bonding parameters in real-time, which significantly improves yield rates and reduces operational costs.

Another key trend shaping the future of wire bonding is the shift towards environmentally sustainable practices. As manufacturers face increasing pressure to reduce their carbon footprint, innovations such as eco-friendly materials and energy-efficient bonding techniques are gaining traction. Additionally, the development of advanced bonding materials, including ultrathin wires and novel adhesives, is facilitating better performance while also addressing environmental concerns. These innovations promise to not only enhance the reliability and longevity of electronic products but also align with the global push for greener manufacturing solutions.

As companies innovate to overcome traditional challenges in the manufacturing sector, the exploration of alternative wire bonding methods is gaining momentum. A number of firms are redefining the landscape by experimenting with innovative techniques that not only improve efficiency but also reduce environmental impact. These pioneers are seeking to address pressing global issues, echoing a wider trend in industries such as construction, where concrete production contributes significantly to carbon emissions.

For instance, the push for sustainability in the construction industry has led to new materials and processes that prioritize lower carbon footprints. Similarly, in the wire bonding arena, companies are embracing alternative solutions that aim to cut down on the energy-intensive practices associated with conventional techniques. Success stories abound as these companies not only enhance their operational efficiency but also position themselves as leaders in the sustainability movement, proving that innovation and environmental responsibility can go hand in hand. Through collaboration and a willingness to challenge the status quo, the future of wire bonding looks promising, showcasing the potential of alternative approaches in adapting to a changing world.

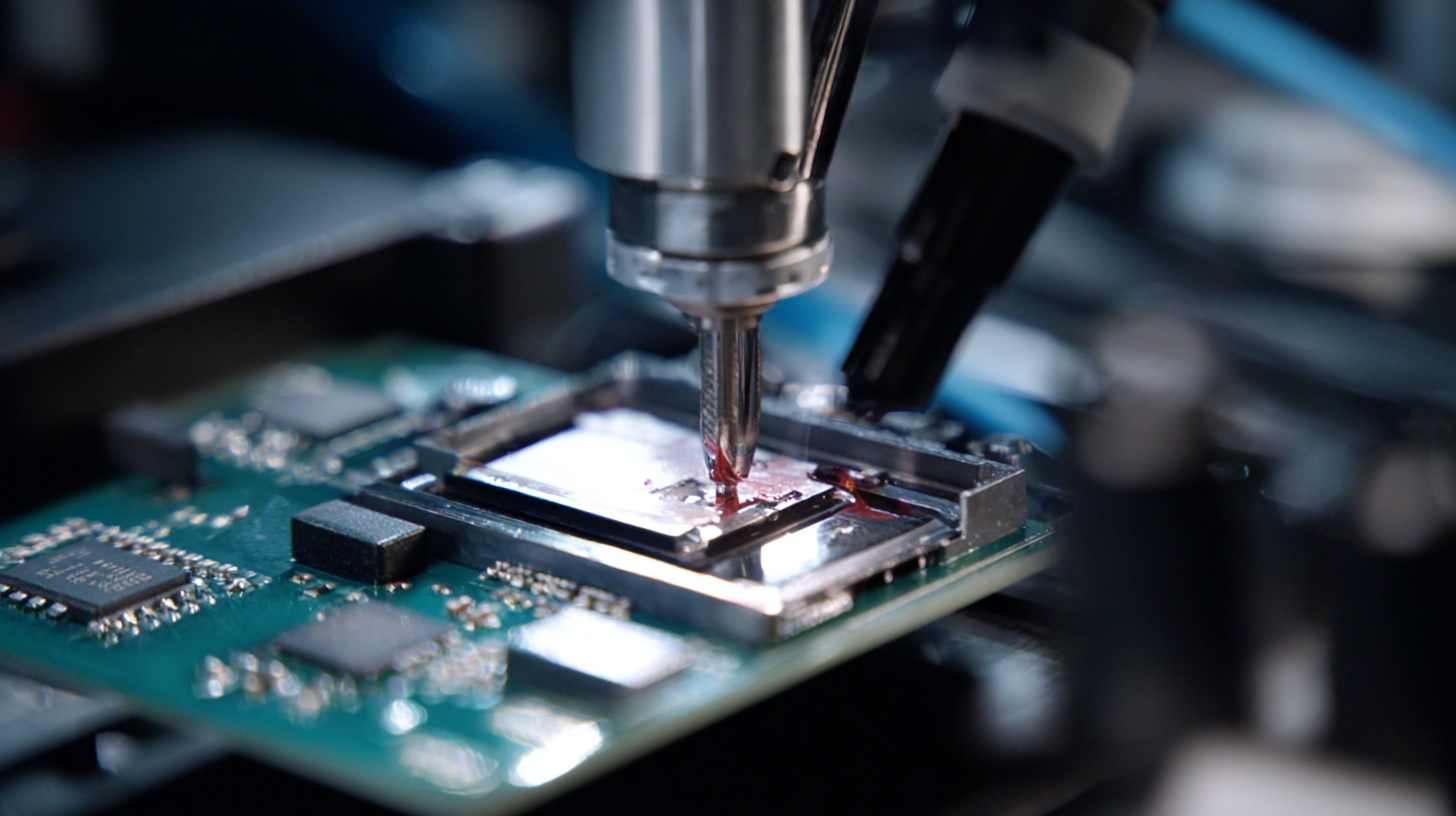

The evolution of wire bonding technologies is facing both challenges and opportunities as we explore innovative alternatives to traditional solutions. With the increasing demand for high-performance applications in sectors like telecommunications and computing, newer materials and methods are essential. Current advancements in silicon, organic, and glass interposer technologies highlight the potential for improved efficiency and functionality. For instance, silicon photonics has emerged as a pivotal technology, driven by its ability to enable faster optical communication—projected to grow at a CAGR of 23.4% from 2021 to 2028, according to industry reports.

Moreover, the shift towards 3D ICs presents unique challenges and solutions in wire bonding processes. These integrated circuits offer reduced footprint and enhanced power efficiency, critical for today’s mobile devices and IoT applications. However, they also pose challenges such as increased thermal management and packaging complexity. The development of hybrid bonding techniques, which allow for denser interconnects, underscores the transformation in wire bonding methods essential for catering to advanced packaging needs. Innovative clad metal solutions are being explored to tackle the demanding requirements of next-generation batteries, presenting a promising avenue for research and development in wire bonding technologies.