In the highly competitive landscape of manufacturing, optimizing Die Pick Up And Place operations has become crucial for enhancing productivity and reducing costs. According to a 2022 report by the International Federation of Robotics, automating pick-and-place tasks can improve efficiency by up to 30%, significantly minimizing cycle times and maximizing throughput. As demand for precision and speed rises, companies are increasingly turning to advanced technologies to streamline their workflows.

The implementation of smart robotics and AI-driven systems in die handling processes not only improves accuracy but also ensures consistent quality, critical in industries such as automotive and electronics. Mastering Die Pick Up And Place operations is therefore not just an operational necessity but a strategic advantage, empowering businesses to meet the ever-evolving demands of the market.

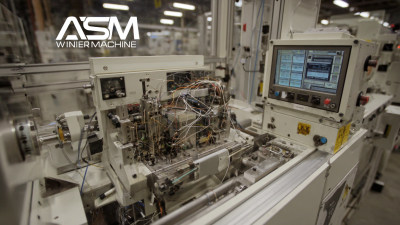

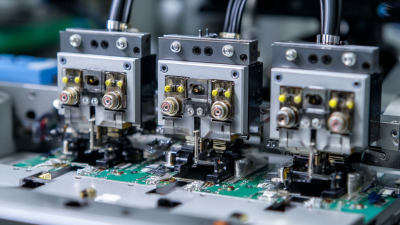

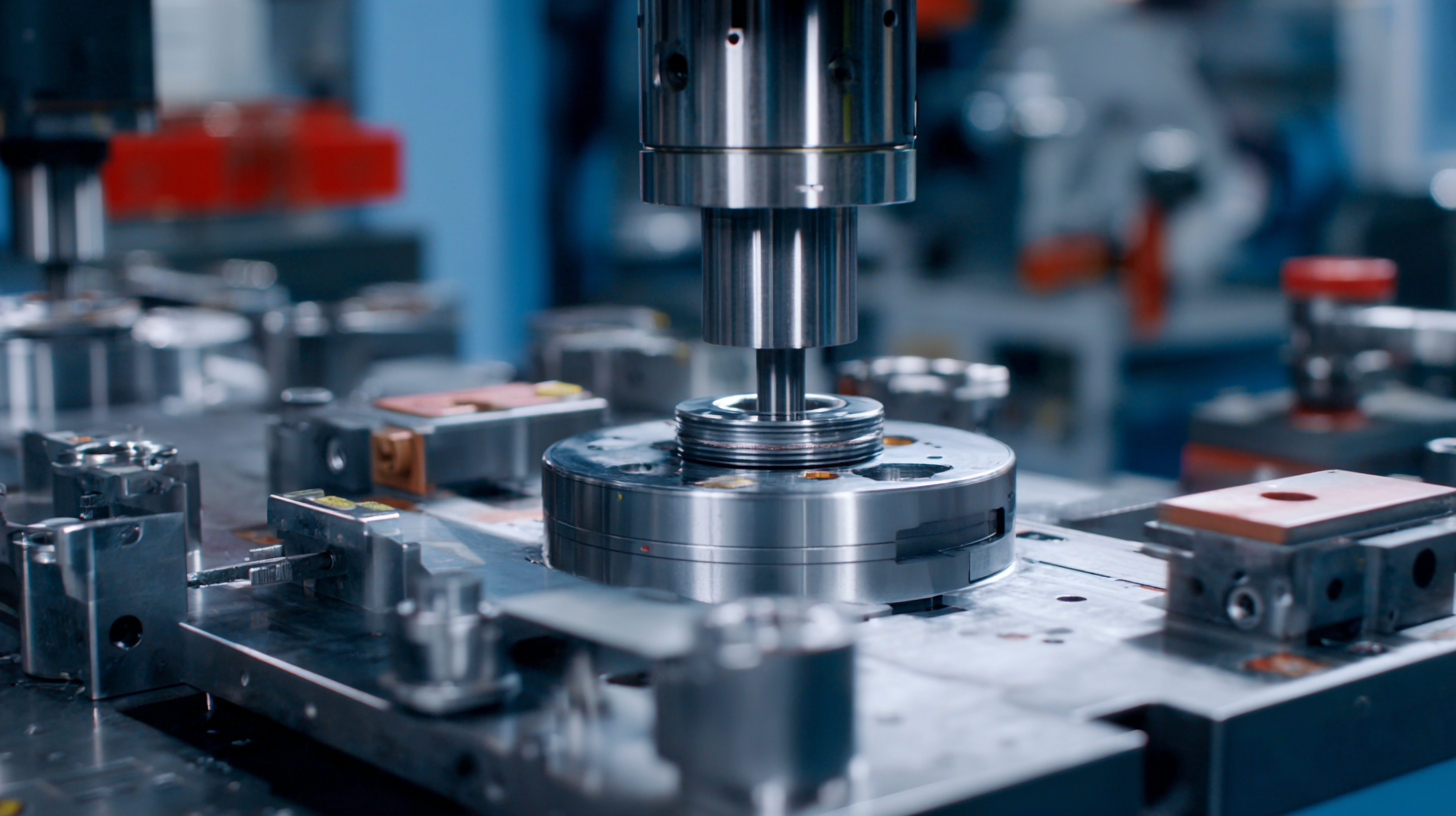

Die pick up and place operations are critical in manufacturing, particularly in the assembly of electronic components and precision instruments. Understanding the fundamentals involves recognizing the intricacies of handling delicate dies, which require both precision and care to prevent damage. The process starts with selecting the appropriate equipment, such as vacuum pick-up tools and robotic arms, which must be compatible with the size and weight of the dies being handled. This ensures effective grip and minimizes the risk of slippage during transfer.

Moreover, mastering the timing and coordination of movements during the pick and place operation is essential. Operators need to synchronize the speed of the equipment with the pace of the manufacturing line to maintain efficiency and accuracy. Additionally, training and familiarity with the tools and visual alignment techniques can greatly enhance performance. By focusing on these foundational aspects, manufacturers can streamline their operations and achieve higher quality outputs, ultimately leading to improved productivity and reduced error rates in die assembly processes.

Measuring efficiency in die pick up and place operations is crucial for improving productivity and quality in manufacturing. Key metrics to consider include cycle time, which tracks the duration from picking up the die to placing it in the intended position. A reduced cycle time often reflects a more efficient process, allowing for greater throughput without compromising quality. Additionally, analyzing the first-pass yield is essential; this metric evaluates how many parts meet quality standards without rework, thereby indicating the reliability of the pick and place system.

Another important metric is the equipment effectiveness rate. This encompasses the operational performance of the machinery involved in the process, accounting for both downtime and production speed. By monitoring equipment effectiveness, organizations can identify areas for improvement and address potential bottlenecks. Other metrics like operator performance and error rates further aid in understanding the overall efficiency of die pick up and place operations. By focusing on these key metrics, companies can optimize their processes and enhance their operational efficiency.

| Metric | Description | Example Value | Target Value |

|---|---|---|---|

| Cycle Time | Time taken to complete one pick up and place operation | 1.2 seconds | 1.0 seconds |

| First Pass Yield | Percentage of correct placements on the first attempt | 96% | 98% |

| Operational Uptime | Percentage of time the die pick and place equipment is operational | 90% | 95% |

| Throughput | Number of units processed in a given time frame | 240 units/hour | 300 units/hour |

| Error Rate | Rate of errors occurring during pick and place | 4% | 2% |

| Setup Time | Time required to prepare the equipment for operation | 15 minutes | 10 minutes |

| Maintenance Frequency | How often the equipment requires maintenance | Monthly | Every 6 weeks |

Die handling operations are critical in manufacturing processes, and reducing cycle time can significantly enhance productivity. One key strategy is to implement effective training programs for operators. Ensuring that personnel are well-versed in the techniques of die pick up and placement can minimize errors and increase efficiency. Proper training can also lead to quicker response times in adjusting to unexpected issues during the operation.

Another best practice for reducing cycle time is to invest in modern equipment that improves automation in die handling. Utilizing automated systems can streamline the pick and place processes, allowing for quicker transfer times between operations. Additionally, regular maintenance of this machinery ensures optimal performance and reduces the likelihood of downtime, thus maintaining a consistent workflow. Pairing technology with streamlined processes will contribute to a more effective die handling operation, ultimately resulting in lower cycle times and higher productivity.

In die pick up and place operations, adhering to safety standards and compliance is of paramount importance. Companies must prioritize creating a safe working environment as part of their operational practices. Effective implementation of a safety and health program involves a structured approach that includes core elements such as hazard identification, risk assessment, and training. By fostering a culture of safety, organizations can minimize risks associated with handling heavy machinery and delicate components during die operations.

Moreover, staying compliant with regulations is essential to prevent workplace accidents and ensure the well-being of employees. Facilities should conduct regular audits and inspections to maintain adherence to industry best practices and legal requirements. As seen in other sectors, such as consumer product safety regulations addressing hazardous substances, the emphasis on compliance can prevent potential health risks and enhance product integrity. Implementing these safety measures not only protects workers but also contributes to the overall efficiency and success of the pick up and place operations.

Die pick up and place operations are critical in various manufacturing processes, where precision and efficiency are paramount. Innovative technologies have emerged to enhance these operations, significantly improving accuracy and reducing cycle times. One of the foremost advancements is the integration of vision systems, which allow robotic arms to identify and align dies with remarkable precision. These systems utilize advanced algorithms and machine learning to ensure that even the most intricate components are handled correctly, minimizing the risk of errors.

Another significant technological development is the implementation of automated guided vehicles (AGVs) equipped with smart sensors. These vehicles can transport dies smoothly across workspaces, reducing human intervention and the potential for manual mistakes. Additionally, the integration of AI-driven software can optimize the pick and place workflow by analyzing production data in real time, anticipating bottlenecks, and suggesting adjustments. This level of automation not only enhances operational efficiency but also contributes to a safer working environment by reducing the chances of accidents associated with manual handling.