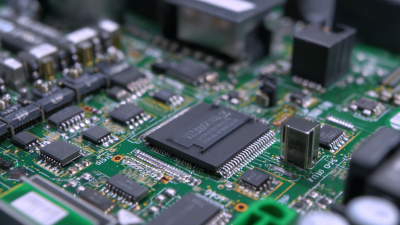

In the realm of modern manufacturing, the significance of Die Bonding Tools cannot be overstated. As the semiconductor industry continues to evolve, with projections indicating a market growth rate of over 5.9% CAGR from 2021 to 2026, the efficiency and precision provided by advanced die bonding solutions have become critical (Source: MarketsandMarkets). These tools not only enhance the reliability of electronic components but also contribute to the overall reduction of production costs. Industry research highlights that improper die bonding can lead to a failure rate of up to 30% in electronic devices, underlining the necessity for sophisticated die bonding techniques. As manufacturers strive to meet increasing demands for compact and efficient devices, understanding and utilizing the latest die bonding tools is essential for achieving optimal performance and quality in production processes.

Die bonding tools play a crucial role in enhancing manufacturing efficiency across various industries, particularly in semiconductor and electronics manufacturing. According to a report by MarketsandMarkets, the global semiconductor manufacturing equipment market is projected to reach USD 83.5 billion by 2025, with die bonding tools being a significant contributor to this growth. These tools are essential for the accurate placement of semiconductor dies onto substrates, and their effectiveness directly influences the yield and quality of the final products.

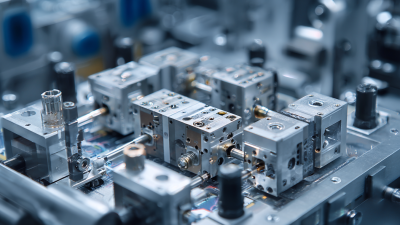

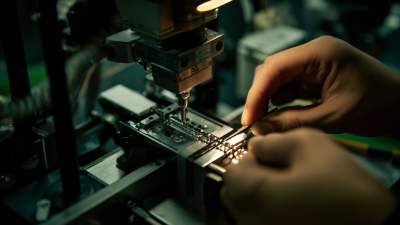

Moreover, advancements in die bonding technology have led to a marked improvement in production speed and reliability. A study published by TechInsights highlights that automated die bonding processes can reduce cycle times by up to 40%, resulting in increased throughput and lower operational costs. The integration of sophisticated die bonding tools, such as automated pick-and-place systems, ensures precision in bonding, which minimizes defects and enhances overall product performance. As industries continue to innovate, the impact of these tools on manufacturing efficiency cannot be overstated, making them indispensable in modern production environments.

The die bonding process is crucial in semiconductor manufacturing, playing a pivotal role in ensuring the reliability and performance of electronic devices. Recent advancements in key technologies have dramatically improved this process. According to a report from Market Research Future, the global die bonding equipment market is projected to grow at a CAGR of 8.5% from 2022 to 2028, indicating a robust demand for efficient bonding solutions. Innovations such as gold wire bonding, epoxy die attachment, and laser-based bonding methods are at the forefront of these improvements, significantly reducing contamination risks and enhancing thermal conductivity in packaged devices.

In this evolving landscape, manufacturers are encouraged to adopt automated die bonding systems which not only improve precision but also increase throughput, a vital factor in meeting rising production demands. For companies looking to enhance their bonding processes, it is crucial to regularly update equipment and technology. As noted in the Semiconductor Industry Association’s report, the proper selection of die bonding materials, such as high-performance adhesives and alloys, can lead to improved production yield and reduced costs.

Tips: Always ensure equipment is well-maintained to prevent unexpected downtimes. Regular training for operators on the latest bonding technologies can also yield significant improvements in both efficiency and product quality. Investing in R&D for new die bonding techniques can keep manufacturers ahead of the competition.

Choosing the right die bonding tools is crucial for optimizing manufacturing efficiency and product quality.

According to a report by the McKinsey Global Institute, the global semiconductor market is projected to reach $1 trillion by 2030, underscoring the importance of precision in this industry.

When selecting die bonding tools, manufacturers should consider factors such as bonding strength, thermal conductivity, and ease of integration into existing production lines.

Tools that offer a robust bond while minimizing thermal degradation are essential, particularly in high-performance applications.

Additionally, a recent study from SEMI indicates that automation in die bonding operations can reduce production costs by up to 25%.

This emphasizes the need for manufacturers to adopt advanced tools that not only ensure high precision and repeatability but also support automation capabilities.

Prioritizing tools that are adaptable and offer advanced features such as real-time monitoring and diagnostics can significantly enhance operational efficiency and product consistency, ultimately leading to a competitive edge in the ever-evolving manufacturing landscape.

The integration of automation into die bonding processes has become increasingly essential in modern manufacturing. As industries strive for enhanced production capabilities, automated die bonding tools enable higher precision and efficiency, addressing the complexities associated with advanced manufacturing systems. Recent advances in fault detection techniques relevant to Industry 4.0 have shown that automated systems can significantly minimize human error and optimize production workflows. For instance, research indicates that automation can reduce costs by up to 20% while improving repeatability in processes—a critical factor for maintaining quality standards in die bonding applications.

Furthermore, the evolution of technologies such as advanced inkjet printing is poised to transform manufacturing, particularly in sectors like electric motor production. Enhanced integration of automation and die bonding can streamline the assembly of e-motors, which are crucial for sustainable mobility solutions. Statistics reveal that incorporating automated processes in manufacturing can lead to a 30% increase in production speed, thereby supporting the ever-growing demand for energy-efficient systems. Manufacturers are increasingly adopting AI and robotics to facilitate heterogeneous integration, proving that the fusion of die bonding tools with automated technologies is not just a trend, but a vital strategy for future-proofing manufacturing processes.

This bar chart illustrates the efficiency improvements in modern manufacturing processes that integrate automated die bonding tools. The data reflects the percentage increase in production speed and reduction in defects over the last five years.

As the landscape of smart manufacturing evolves, die bonding tools are becoming increasingly sophisticated, integrating advanced technologies like automation and data analytics. These tools are essential for achieving high precision and efficiency, which are critical in the production of semiconductors and other electronic components. Future trends suggest a shift towards more intelligent die bonding solutions that not only improve operational capabilities but also enhance the overall quality of manufactured products.

Tips for implementing die bonding tools in smart manufacturing include investing in automation technologies that can streamline the bonding process and reduce human error. Additionally, consider utilizing predictive maintenance techniques to minimize downtime and ensure that equipment runs at optimal performance. Regular training for personnel on the latest technologies can also foster a culture of innovation and adaptability within the workforce.

Moreover, the integration of artificial intelligence (AI) in die bonding tools is predicted to optimize the process further by enabling real-time monitoring and adjustments. This capability will allow manufacturers to respond faster to production challenges and enhance the overall agility of their operations. Embracing these advancements will be key to maintaining a competitive edge in the rapidly changing manufacturing sector.