As we move closer to 2025, the landscape of semiconductor manufacturing is poised for significant transformation, particularly in the domain of Automatic Wire Bonding. This sophisticated process has long been a cornerstone in the assembly of integrated circuits, ensuring both reliability and performance. However, emerging trends suggest that advancements in technology and evolving market demands are paving the way for new approaches and innovative solutions that could redefine the future of Automatic Wire Bonders. From enhanced automation and artificial intelligence integration to alternative bonding techniques, industries are exploring diverse options that promise to optimize efficiency and reduce costs. In this blog, we will delve into these emerging trends, examining how they are shaping the future of Automatic Wire Bonding and the potential solutions that can meet the challenges of tomorrow's semiconductor landscape.

As we move into 2025, automatic wire bonding is on the brink of a technological revolution, driven by several emerging technologies. One of the most significant advancements is the integration of artificial intelligence and machine learning into the bonding process. These technologies enhance precision and efficiency by enabling real-time monitoring and adjustments, thus minimizing defects and reducing material waste. The application of AI allows for iterative learning from production data, optimizing parameters such as bonding time and pressure to ensure superior quality.

Additionally, advances in materials science are bringing forth alternative bonding solutions that challenge traditional methods. Innovative materials such as ultra-thin bonding wires and new adhesive systems are being developed, resulting in lighter, more reliable connections that can support the increasing demands of miniaturized electronic components. The trend towards higher-frequency applications in communication devices also necessitates these alternatives, as they can provide lower inductance and improved thermal performance. This fusion of AI-driven processes with new materials underscores a pivotal shift in how the industry approaches wire bonding, setting the stage for smarter, more sustainable manufacturing practices in the near future.

As we approach 2025, the integration of artificial intelligence (AI) in the wire bonding industry is poised to revolutionize efficiency and precision. According to a recent market analysis by Research and Markets, the global wire bonding equipment market is expected to grow from $1.9 billion in 2022 to $2.7 billion by 2026, with AI-driven technologies being a significant contributor to this rise. The ability of AI to analyze vast datasets in real-time allows for optimized bonding processes, reducing errors and improving yield rates.

AI systems equipped with machine learning algorithms can predict equipment failures and adjust parameters on the fly, enhancing operational reliability. For instance, a study by Deloitte indicates that manufacturers employing AI in their production lines could see up to a 20% improvement in efficiency. By utilizing advanced imaging and sensor technologies, AI can also ensure the accuracy of bond placement, which is critical in reducing the failure rates of semiconductor devices. This trend highlights a transformative shift wherein AI is not merely an add-on but a core component driving the future of automatic wire bonding solutions.

This chart illustrates the projected efficiency and precision improvements in automatic wire bonding processes due to the integration of artificial intelligence solutions. The data highlights the trend towards enhanced performance metrics from 2023 to 2025.

As we approach 2025, the landscape of automatic wire bonding and its alternatives is poised for significant transformation. Market growth projections indicate a substantial rise in demand for innovative bonding solutions driven by the increasing complexity of electronic devices and the need for improved performance. Industries such as automotive, telecommunications, and consumer electronics are fueling this growth as they seek more efficient methods of interconnecting components while enhancing reliability and reducing costs.

Emerging technologies such as hybrid bonding and advanced adhesive solutions are gaining traction as viable alternatives to traditional wire bonding. These alternatives not only offer enhanced flexibility and scalability but also present opportunities for miniaturization and integration of more intricate designs. As manufacturers prioritize efficiency and sustainability, the evolution of bonding techniques is set to redefine electronic assembly processes, leading to more robust and compact products tailored for the next generation of applications.

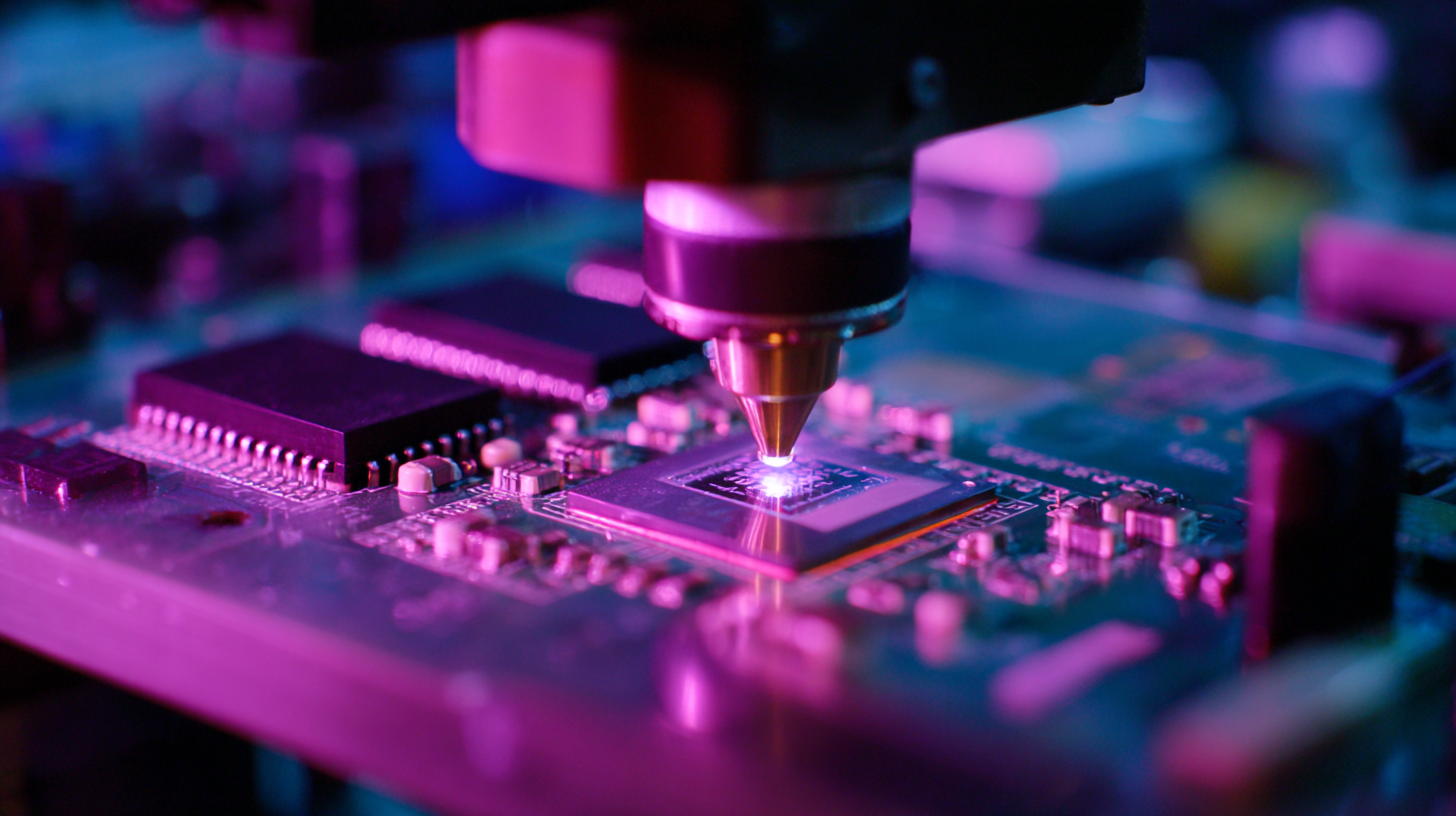

As we look towards 2025, the landscape of automatic wire bonding continues to evolve, driven by innovative techniques that enhance both efficiency and quality. In China, several case studies illustrate the successful implementation of these emerging wire bonding technologies. For instance, a leading semiconductor manufacturer recently adopted laser-based wire bonding, which not only reduced cycle time but also minimized thermal stress on delicate components. This innovative approach has set a new standard for reliability and performance in the market.

Another compelling example comes from a burgeoning startup in Shenzhen that integrated advanced ultrasonic bonding techniques into their assembly line. By leveraging these cutting-edge methods, the company significantly improved bond strength and reduced material costs. The results have been promising, demonstrating how alternative solutions can lead to superior outcomes without compromising on quality. These case studies highlight the transformative potential of new bonding technologies in China, showcasing a commitment to advancing the semiconductor industry while addressing the growing demand for efficient production processes.

| Case Study | Technology Used | Outcome | Region | Year Implemented |

|---|---|---|---|---|

| Case Study 1 | Advanced Ultrasound Bonding | Increased bond reliability by 30% | Eastern China | 2024 |

| Case Study 2 | Laser Bonding Technology | Reduced production time by 20% | Southern China | 2023 |

| Case Study 3 | Plasma Treatment Technology | Enhanced adhesive performance | Northern China | 2025 |

| Case Study 4 | Hybrid Bonding Techniques | Cost savings of 15% | Western China | 2022 |

As the landscape of manufacturing evolves, the focus on cost-effectiveness in bonding technologies becomes increasingly critical. In 2025, traditional automatic wire bonding methods are facing stiff competition from innovative alternatives. This comparative analysis highlights the distinct advantages offered by newer bonding techniques not only in terms of cost savings but also in enhancing performance and sustainability. For instance, utilizing atmospheric plasma activation (APA) has shown promising results in surface treatment, significantly improving bond quality—an aspect traditional methods struggle to achieve efficiently.

Additionally, the market is seeing a rise in demand for sustainable practices. Alternative bonding methods, which incorporate eco-friendly materials and processes, align with the growing emphasis on sustainability within the industry. While traditional wire bonding has been a reliable mainstay, its limitations in flexibility and adaptability pave the way for advanced solutions that promise better results and lower environmental impact. Thus, navigating these emerging trends is vital for manufacturers aiming to maintain competitive advantage while also catering to a more environmentally conscious consumer base.