In the realm of semiconductor manufacturing, the technique of "Die Pick Up and Place" plays a crucial role in ensuring precision and efficiency during the assembly process. As industry expert Dr. Emily Carter, a leading figure in automation technologies, aptly stated, "The accuracy of Die Pick Up and Place operations can significantly enhance the overall yield and reliability of semiconductor devices." This statement underscores the importance of advanced methods utilized in the handling and placement of delicate semiconductor dies.

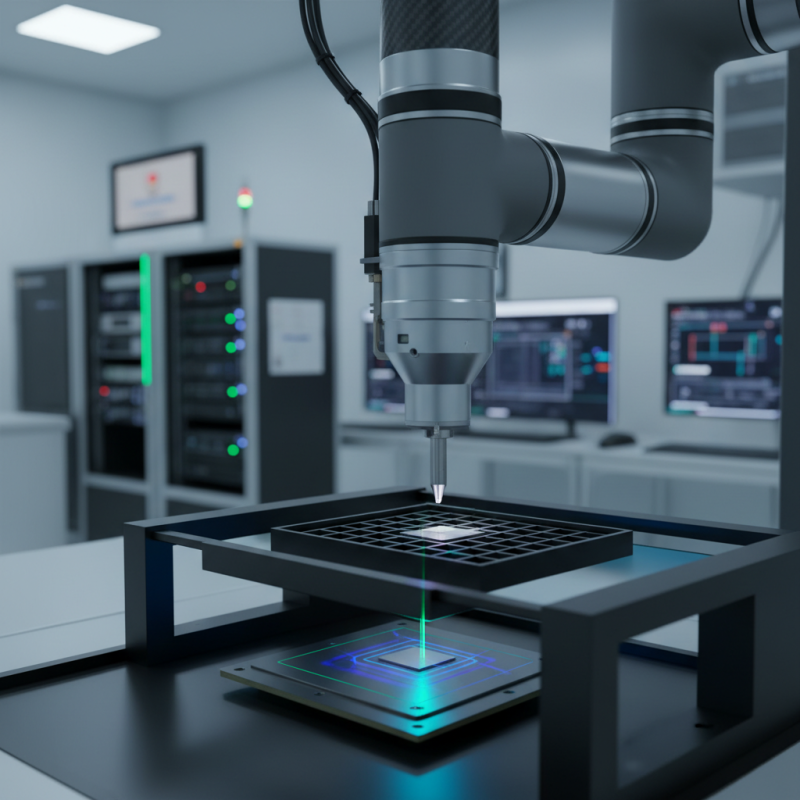

Die Pick Up and Place not only streamlines production but also integrates sophisticated automation and robotics, resulting in higher throughput and reduced human error. Companies continuously seek innovative solutions in this domain, unlocking benefits that extend beyond mere operational efficiency. By harnessing cutting-edge technologies, the Die Pick Up and Place process has transformed from a manual task to a highly specialized automated function, integral to modern manufacturing strategies.

Furthermore, the applications of Die Pick Up and Place are vast and varied, spanning numerous sectors within electronics and beyond. From automotive components to consumer electronics, understanding the nuances of this technique is essential for overcoming contemporary manufacturing challenges. As we delve deeper into the techniques, benefits, and diverse applications of Die Pick Up and Place, the significance of this operation becomes even more apparent in shaping the future of assembly processes.

Die pick up and place is an essential process in various manufacturing settings, particularly in the electronics and semiconductor industries. This technique involves the precise handling and placement of dies, which are small pieces of semiconductor material. Several methods are commonly employed in die pick up and place operations, including robotic automation, manual handling, and advanced vision systems. According to a report by the International Robotics Federation, the use of robotic systems in semiconductor manufacturing has seen an annual growth rate of approximately 15%, reflecting the increasing demand for efficiency and precision in the industry.

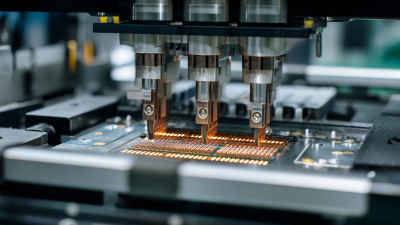

Advanced techniques such as vacuum-based pick-up and machine vision integration significantly enhance the reliability and speed of die placement. For example, vacuum pick-up systems utilize suction to securely hold and maneuver dies, ensuring minimal damage during transfer. Additionally, machine vision technology allows for real-time quality inspection and alignment verification, reducing error rates and increasing productivity. A comprehensive study from the Semiconductor Equipment and Materials International (SEMI) revealed that integrating machine vision systems in manufacturing processes can lead to a 20% improvement in overall process efficiency and a 30% reduction in defects.

The benefits of employing these die pick up and place techniques extend beyond operational efficiency. By enhancing precision and reliability, companies can reduce material waste and lower production costs. According to market analysis conducted by MarketsandMarkets, the global market for die attach equipment is projected to reach $1.72 billion by 2025, driven by the growing demand for miniaturized electronics and innovative packaging solutions. This signifies a shift in the industry towards technologies that optimize die handling processes, ensuring higher performance and profitability in semiconductor manufacturing.

Die pick up and place systems are increasingly essential in the manufacturing and assembly industries, offering several key advantages that enhance production efficiency and reduce operational costs. According to a recent industry report by Research and Markets, the global market for automation solutions, including die pick up and place systems, is projected to reach $200 billion by 2025. This growth is largely driven by the demand for higher precision and faster production speeds, which these systems can deliver.

One of the primary benefits of these systems is their ability to minimize human error. With automation technology, tasks that require precise placement of components can be executed with millimeter accuracy. A 2023 study highlighted that factories utilizing die pick up and place systems reduced assembly errors by up to 30%, leading to substantial savings in rework and material costs. Furthermore, the implementation of these systems allows manufacturers to reallocate human resources to more complex tasks, thereby enhancing overall productivity.

Additionally, die pick up and place systems contribute to greater scalability in production lines. As companies adapt to fluctuating market demands, the ability to integrate or upgrade automated systems quickly becomes paramount. The International Federation of Robotics reports that companies employing flexible manufacturing solutions, including pick and place technologies, have seen a 20% increase in output during peak production times without compromising quality. These key advantages make die pick up and place systems not just a valuable asset, but a vital component in maintaining competitive advantage in today’s fast-paced manufacturing landscape.

Die pick up and place is a critical technique used across various industries, particularly in the manufacturing and electronics sectors. One of the most common applications of this method is in the assembly of microelectronic components. The precise placement of dies onto substrates is essential for ensuring the functionality and reliability of electronic devices. Automated systems equipped with advanced vision technologies can efficiently locate and manipulate these delicate components, minimizing the risk of damage during the process.

Another notable application is in the automotive industry, where die pick up and place is employed for assembling sensors and circuit boards that are integral to modern vehicles. These systems enhance production speed and consistency, allowing manufacturers to meet the high demand for advanced automotive technologies. Additionally, in the semiconductor industry, this technique supports the production of integrated circuits by enabling the accurate and rapid placement of various dies during the fabrication process, ensuring optimal performance and yield rates in the final products.

In the realm of semiconductor manufacturing, the method of die placement is critical for ensuring product quality and efficiency. When comparing die pick up and manual placement methods, it's essential to recognize the strengths and weaknesses of each. Die pick up techniques, typically automated, enhance speed and precision by utilizing advanced machinery that can accurately position dies with minimal human intervention. This results in reduced risk of error and higher throughput, making it ideal for high-volume production environments.

On the other hand, manual placement methods offer higher flexibility and control, particularly in low-volume or prototype manufacturing scenarios. Operators can quickly adjust their approach based on individual die characteristics or unique assembly requirements. However, this method can be labor-intensive and prone to inconsistencies, particularly as production scales up.

As the semiconductor industry evolves, so does the technology behind die pick up and place. Future trends indicate a shift towards greater automation and integration of advanced materials, enhancing efficiency and precision. These innovations are expected to reduce cycle times while improving yields, thereby pushing the boundaries of miniaturization and functionality of electronic devices. The adoption of artificial intelligence in these systems is also on the rise, allowing for real-time adjustments and quality control during the die assembly process.

Tips: When considering die pick up and place systems, focus on automation capabilities that can adapt to varying production sizes. Additionally, investing in training for staff on the latest technologies can significantly enhance operational effectiveness.

Moreover, the application of machine learning algorithms for predictive maintenance is gaining traction. This proactive approach minimizes downtimes by anticipating potential failures and scheduling maintenance, thereby ensuring continuous production flow. Emphasizing sustainability, the industry is also moving towards environmentally friendly materials and processes, promoting a greener approach to die assembly.

Tips: Stay informed about emerging technologies and methodologies in die handling. Engage with industry experts and attend conferences to keep abreast of best practices and innovations.

This chart demonstrates the trends in the efficiency of die pick up and place technologies over the past few years, showcasing the improvement in speed and accuracy.