When it comes to maximizing efficiency and precision in electronic manufacturing, selecting the right Tpt Wire Bonder is crucial. According to a recent report by Markets and Markets, the global wire bonding market is projected to reach USD 5.3 billion by 2025, driven by the increasing demand for miniaturized devices and advanced interconnect technology. Tpt Wire Bonders play a pivotal role in ensuring reliable connections in semiconductor packaging, making it essential for production managers to consider critical factors such as bond quality, speed, and versatility. As manufacturers strive to enhance production capabilities and minimize downtime, a well-informed choice of a Tpt Wire Bonder can lead to significant improvements in operational efficiency and product quality. In this blog, we will provide a comprehensive checklist for evaluating the best Tpt Wire Bonder tailored to your production needs.

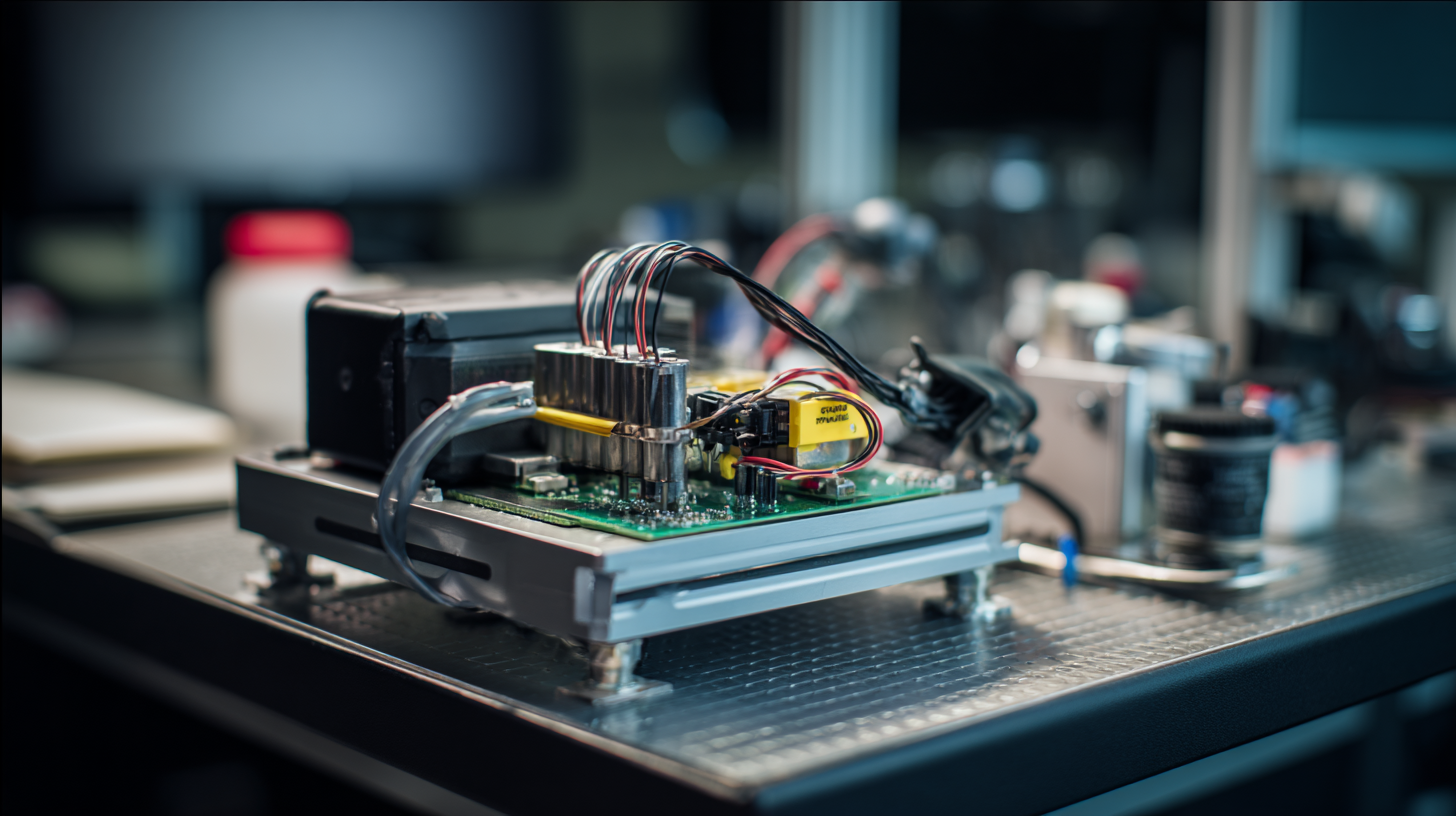

Selecting the right Tpt wire bonder requires an understanding of the various types available in the market. Primarily, there are two categories of wire bonders: thermosonic and thermocompression. Thermosonic bonders use heat and ultrasonic energy to create strong connections, making them ideal for applications requiring precision and reliability, such as in semiconductor packaging. On the other hand, thermocompression bonders rely solely on heat and pressure to achieve bonding, which is often suitable for materials sensitive to ultrasonic energy.

When choosing a Tpt wire bonder, consider the type of materials you will be working with. Some materials, like gold or aluminum, pair better with specific bonding technologies. Additionally, assess your production volume. If high-throughput is essential, automated bonders with higher speed and efficiency may be your best bet.

Tip: Always opt for a bonder that offers adaptability in wire size and bonding parameters to cater to future production needs. Regularly review technological advancements in bonding technologies to ensure you are making the most informed decision. It's also beneficial to seek out customer reviews and expert recommendations to narrow down suitable options as you navigate the market.

When selecting a Tpt wire bonder for your production needs, it’s crucial to consider key features that can significantly impact your manufacturing efficiency and product quality. One of the first elements to evaluate is the bonding technology employed by the wire bonder. According to a report by Gartner, automated wire bonding technologies can improve production throughput by up to 30%, making it essential to assess whether the bonder utilizes thermosonic, wedge, or ball bonding techniques, based on your specific requirements.

Additionally, reliability and flexibility are paramount. A study published in the Journal of Semiconductor Technology examined various bonders and found that those with programmable settings for different production runs saw a 25% reduction in downtime. Look for models that offer adaptive bonding capabilities, which allow you to switch easily between different wire types and bond configurations. These features not only enhance overall productivity but also contribute to lower operational costs, aligning perfectly with modern production demands.

Choosing the right Tpt wire bonder is crucial for optimizing your production processes. A well-suited wire bonder can significantly enhance productivity by ensuring consistent performance and high-quality bonding. Different models come with unique features tailored for specific applications, allowing manufacturers to meet varying demands efficiently. Understanding your production needs, whether you require speed, flexibility, or precision, is essential in evaluating the benefits of a particular wire bonder.

Moreover, selecting a Tpt wire bonder with the right capabilities can lead to cost savings in the long run. By investing in a machine that aligns with your production goals, you minimize the risk of downtime and defects, boosting overall efficiency. Furthermore, the right wire bonder can streamline training and integration within your existing workflow, facilitating a smoother transition and faster ramp-up time. The benefits of making the right choice resonate through improved quality and reduced operational costs, solidifying your production line's success.

When selecting a Tpt wire bonder, balancing cost with quality is crucial for optimizing production efficiency. Current industry trends indicate that companies are increasingly moving towards automated solutions, which, while initially more expensive, can result in long-term savings. According to a recent report, investing in high-quality bonding equipment can reduce defect rates by up to 30%, significantly impacting overall production costs.

Tips: Before making a purchase, consider the total cost of ownership (TCO), which includes maintenance, operation, and potential downtime costs. It's essential to evaluate not just the sticker price of the bonder but also how it will perform over time in your specific application.

Additionally, be mindful of the technology advancements in wire bonding machines. The latest models incorporate enhanced features like real-time monitoring and adaptive control, allowing for greater flexibility and higher throughput, potentially offsetting initial capital outlay.

Tips: Seek equipment that offers scalability to meet future production demands. This foresight can prevent costly upgrades in the near term, ensuring that your investment remains viable as market needs evolve.

When it comes to wire bonding, ensuring the longevity of your Tpt Wire Bonder is crucial for maintaining production efficiency and minimizing downtime. Regular maintenance is essential, as it prevents wear and tear on the equipment. Establish a routine cleaning schedule to remove any debris or dust that may affect performance. Use appropriate cleaning materials that do not damage the components, and pay particular attention to the bond head and ultrasonic stack, which are vital for optimal function.

In addition to cleaning, it's important to stay on top of software updates and technical support. Many manufacturers offer regular updates that enhance the bonding process and improve machine stability. Leverage these updates and ensure your staff is trained to understand the new features they bring. Don't hesitate to reach out to the manufacturer for support; they can provide valuable insights to troubleshoot issues and improve performance.

Lastly, keep a watchful eye on wear parts and replace them proactively. Components, such as capillaries and bonds, can significantly affect the quality of your work. By implementing a system to monitor their condition, you can prevent unexpected failures. Regularly reviewing and updating your maintenance protocol will help sustain your Tpt Wire Bonder in top condition, ensuring you meet your production needs effectively.