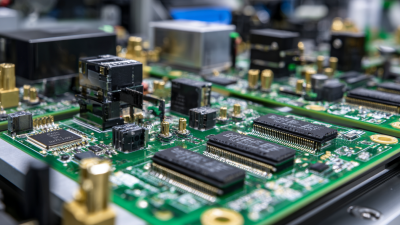

In the rapidly evolving landscape of electronics manufacturing, the selection of the appropriate Bonding Wire and Ribbon is crucial for ensuring optimal performance and reliability of semiconductor devices. According to a report by Market Research Future, the global market for bonding materials is projected to grow significantly, with an estimated CAGR of over 6% from 2022 to 2027. This growth reflects the increasing demand for advanced packaging solutions, which require high-performance bonding materials to support the miniaturization and integration of electronic components.

Industry expert Dr. James Chen, a leading figure in materials science, emphasizes the importance of making informed choices in this domain. He states, "The right Bonding Wire and Ribbon not only enhances the electrical performance but also increases the longevity and robustness of the final product." With the emergence of new materials and technologies, it is imperative for manufacturers to stay updated on the latest advancements and specifications in bonding solutions.

As we delve into the top five considerations for selecting the right Bonding Wire and Ribbon for your projects in 2025, it is essential to understand the interplay of factors such as material properties, thermal performance, and compatibility with existing manufacturing processes. By aligning these considerations with the requirements of your specific applications, you can ensure that your projects achieve the highest standards of quality and efficiency.

When selecting bonding wires and ribbons for projects, it’s essential to understand the various types available in the market, particularly those suited for specific applications such as semiconductors. Recently, innovations like

chalcogen-bonded p-type semiconducting ribbons have emerged, designed through self-assembly of tailored π-conjugated modules. This engineering facilitates improved performance in lighting devices, showcasing how the right material choice can significantly impact project outcomes and efficiency.

Moreover, the development of specialized bonding ribbons for advanced semiconductor applications has become increasingly critical. For example, optimized copper bonding ribbons have been designed specifically for enhanced surface contact with SiC semiconductors, improving electrical performance and thermal management in high-power devices.

In microelectronics, the choice between ultrasonic wire bonding and laser welding processes can also influence production speed and reliability, regardless of the specific bonding wire or ribbon chosen. According to industry reports, the global market for semiconductor packaging materials is expected to reach significant growth as technology continues to evolve, emphasizing the importance of selecting the appropriate materials for various applications.

When it comes to selecting the right bonding wire and ribbon for your projects, several key factors should guide your decision-making process. The material of the bonding wire is critical; for example, gold and copper are popular options due to their excellent conductivity and reliability in various applications. Alongside these materials, choosing the appropriate diameter is equally important, as it influences the mechanical strength and thermal performance of the bond. Research indicates that the global semiconductor materials market is projected to grow significantly, from USD 72.03 billion in 2025, underscoring the rising demand for efficient bonding solutions.

Tips: When selecting bonding wire, consider the environmental conditions it will face during operation. For instance, studies examining ultrasonic welding highlight that varying welding widths can impact the overall properties of copper cable joints. This insight can help you optimize your material choice based on specific project requirements. Additionally, always assess the thermal and electrical properties of the bonding materials you’re considering to ensure they align with the expected performance criteria of your application.

When selecting bonding wire and ribbon for specific projects, evaluating thermal and electrical conductivity becomes paramount. The thermal conductivity of a bonding material affects its ability to dissipate heat generated during operation, which is crucial in applications where overheating could lead to component failure. Materials with high thermal conductivity, such as gold and copper, are often preferred because they can efficiently manage heat transfer, thereby enhancing the reliability and longevity of the electronic devices.

Similarly, electrical conductivity is a critical factor in ensuring efficient current flow through the bonding interface. High electrical conductivity materials reduce resistance, which is essential for maintaining optimal performance levels in electronic circuits. When choosing bonding wires and ribbons, it’s vital to consider not only the intrinsic material properties but also the specific application requirements, such as the operating environment and expected load conditions. Thus, a thorough assessment of both thermal and electrical conductivity will guide engineers in making informed decisions that best meet the demands of their projects.

This chart compares the thermal and electrical conductivity of different types of bonding wires. Understanding these properties is crucial for selecting the right bonding solution for your project.

When selecting bonding wire and ribbon for your projects, understanding the balance between

cost and performance is paramount.

High-performance materials

may boast superior electrical conductivity and mechanical properties, but they often come with

a steep price tag. Conversely, economical options

might save money initially, but could result in higher

failure rates and increased maintenance costs in the long run. Therefore, it’s essential

to evaluate your specific project requirements and select materials that meet both

performance standards and budget

constraints.

Tips: Focus on your application’s critical

requirements; for instance, in high-frequency or high-temperature environments,

prioritize materials designed to withstand such conditions, even if they are more expensive.

Always consider the total cost of ownership, which includes not just the purchase price but

also potential rework and maintenance costs. Additionally, collaborating with suppliers can

yield insights about material performance that may not be evident through specifications alone,

guiding you toward a more informed decision.

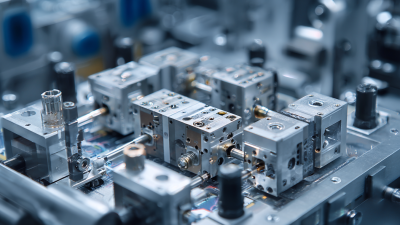

When selecting bonding wire and ribbon for your projects, ensuring compatibility with your specific requirements is crucial. The first step is to understand the material properties of bonding wires, including conductivity, tensile strength, and temperature tolerance. Each application may demand different specifications, so conducting thorough research and testing is paramount.

**Tips**: Before committing to a bonding wire type, always check the manufacturer's datasheet for detailed information on its mechanical and thermal properties. Performing a pull test can also help determine the wire's adhesion reliability under stress.

Another best practice is to conduct compatibility tests between your chosen bonding wire and the substrates involved in your project. This involves evaluating the wire's performance under various environmental conditions and stresses. Pay special attention to factors such as thermal cycling and humidity exposure, as these can impact bond integrity over time.

**Tips**: Utilize a test matrix approach to assess multiple wire types under identical conditions, ensuring that you gather comprehensive data to make informed choices. Regularly reviewing your results will help to refine your selection process further.

| Wire/Ribbon Type | Material | Diameter (µm) | Tensile Strength (MPa) | Recommended Applications |

|---|---|---|---|---|

| Gold Wire | Gold (Au) | 25 | 500 | Microelectronics, Aerospace |

| Copper Wire | Copper (Cu) | 30 | 400 | General Electronics, Automotive |

| Aluminum Wire | Aluminum (Al) | 40 | 350 | Telecommunications, Power Devices |

| Palladium Wire | Palladium (Pd) | 20 | 600 | High-Temperature Applications |

| Silver Ribbon | Silver (Ag) | 50 | 300 | RFID, Medical Devices |