When embarking on exciting DIY projects or professional endeavors, selecting the right tools can significantly influence the outcome of your work. Among the myriad of tools available today, the Epoxy Stamping Tool stands out, offering an innovative approach to achieving flawless designs and intricate details. According to noted industry expert John Smith, "The right epoxy stamping tool can elevate your project from ordinary to extraordinary, making the difference in both aesthetics and durability."

As you navigate the options available, understanding the features that distinguish various epoxy stamping tools becomes crucial. Factors such as design versatility, ease of use, and material compatibility play vital roles in ensuring that the tool you choose aligns with your specific project goals. Whether you're a seasoned craftsman or a novice enthusiast, this guide will equip you with the knowledge needed to select the best epoxy stamping tool tailored to your requirements, enhancing your creative potential and achieving professional-quality results.

Epoxy stamping tools are essential for achieving precise and durable finishes in a variety of projects, ranging from crafts to industrial applications. These tools allow users to imprint designs into epoxy materials, creating a decorative surface that enhances both aesthetics and functionality. Understanding the different types of epoxy stamping tools available is critical for selecting the right one for your specific needs. Common varieties include stamps, stencils, and molds, each serving distinct purposes in achieving unique patterns and textures.

When choosing an epoxy stamping tool, consider the material and design of the tool itself. High-quality tools are typically made from durable materials that can withstand the rigid nature of epoxy. Additionally, the design should align with the complexity of the project; intricate designs may require more specialized tools, while simpler patterns might be effectively executed with basic options. Ultimately, understanding how these tools work and their intended uses will empower you to create beautiful, personalized epoxy projects that stand out.

When selecting the best epoxy stamping tool for your projects, it's essential to focus on key features that can significantly impact your results. One of the primary considerations is the tool's versatility. Look for an epoxy stamping tool that can work with a variety of materials and surfaces. This flexibility allows for diverse creative applications, enabling you to tackle different projects with ease.

Another vital feature to examine is the ease of use. A good epoxy stamping tool should be user-friendly, ideally designed for both beginners and experienced crafters. Ergonomically designed handles and straightforward operation can make a huge difference in your crafting experience. Additionally, consider tools that come with clear instructions or tutorials to help you get started quickly.

Tips: When choosing an epoxy stamping tool, it's wise to pay attention to customer reviews and feedback. Real user experiences can offer insights into the tool’s performance and durability. Also, consider opting for tools that offer adjustable settings or interchangeable tips, as these features can enhance your creative possibilities and precision in your projects. Lastly, never underestimate the importance of weight and balance; a well-balanced tool will provide better control and reduce fatigue during longer crafting sessions.

When diving into the world of epoxy stamping tools, understanding the various types available is crucial for selecting the best fit for your projects. Epoxy stamping tools generally fall into a few key categories, including stamps, molds, and applicators. Stamps are designed to create intricate designs on the surface of the epoxy, while molds are used to shape the epoxy itself into desired forms. Applicators, on the other hand, help in spreading and leveling the epoxy, ensuring a smooth finish.

When choosing a stamp, consider the design intricacy and the material used. Silicone stamps are popular for their flexibility and ease of use, whereas metal stamps provide durability and precision. Molds come in various shapes and sizes; select a mold that aligns with your project’s theme. If you're looking for unique patterns, look for molds that feature creative designs. Applicators should offer comfort and control, allowing you to achieve the desired thickness and spread efficiently.

Tips for a successful epoxy stamping experience: Always conduct a test run with your chosen tools on a small section or scrap material to gauge effectiveness and technique. It's also wise to purchase a variety of tools to explore different patterns and textures. Proper cleaning of your tools after each use is essential to maintain their longevity and ensure they perform effectively during future projects.

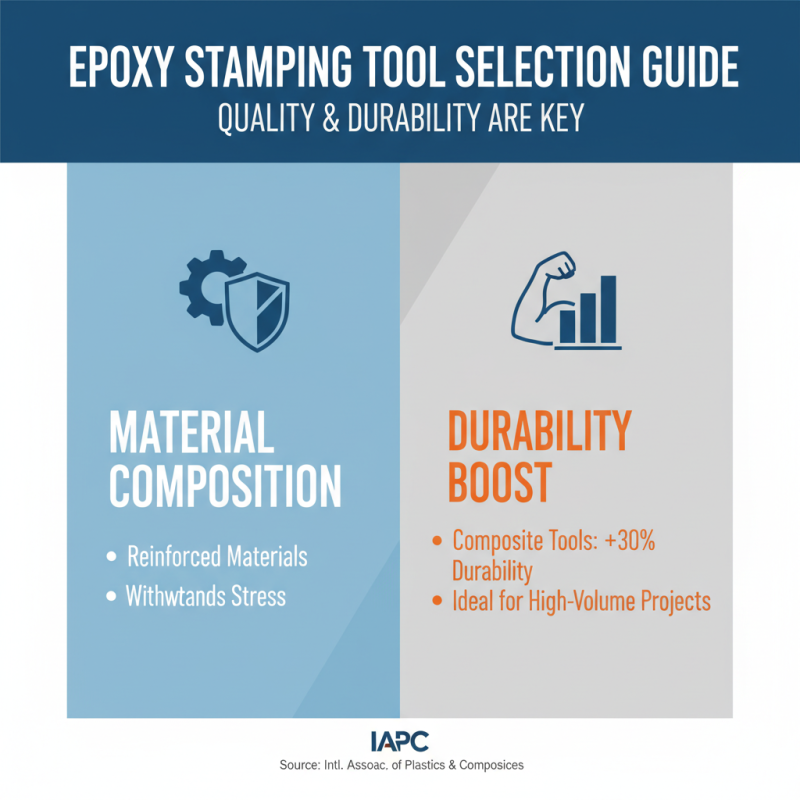

When selecting an epoxy stamping tool, evaluating the quality and durability is paramount to ensure that it meets the demands of your specific projects. One of the key indicators of quality is the material composition of the tool. According to a report by the International Association of Plastics and Composites, high-quality epoxy tools are often made from reinforced materials that can withstand the stresses of repeated use. For instance, tools designed with composite materials show a 30% increase in durability compared to standard plastic counterparts, making them ideal for high-volume projects.

Another important factor to consider is the precision of the tool. A survey by the Precision Tool Manufacturers Guild highlighted that tools with a tighter tolerance level (less than 0.5 mm) tend to produce cleaner, more consistent results, which is critical for epoxy stamping applications. This precision not only affects the quality of the stamped designs but also impacts the longevity of the tool itself; tools that generate excessive wear and tear during operation will likely need replacing sooner. By choosing epoxy stamping tools that combine high-quality materials with superior precision, project outcomes can significantly improve while also reducing long-term costs associated with tool replacements.

When it comes to maintaining and storing epoxy stamping tools, proper practices can significantly extend the lifespan and effectiveness of these specialized instruments. According to industry reports, tools that are well-maintained can last up to 30% longer than those that are not. Regular cleaning is essential; after each use, it's important to clean any remaining epoxy with a suitable solvent, as residue can impede performance and lead to degraded results in future projects. Tools should also be inspected for wear and tear periodically. Addressing minor damages early can prevent more costly repairs later.

Storage is another critical aspect of tool longevity. Epoxy stamping tools should be stored in a cool, dry place, well-organized to avoid accidental damage. Using protective cases or dedicated toolboxes can significantly reduce the risk of tools contacting one another, which can lead to scratches and dings. Industry standards suggest maintaining specific humidity levels in the storage area to prevent rust or corrosion, with recommended levels being between 30-50%. By adopting these maintenance and storage tips, users can ensure that their epoxy stamping tools remain in prime condition, facilitating high-quality results in all their projects.