Selecting the right die pick up tools and collets for your projects can be challenging. These components play a crucial role in achieving precision in machining applications. Understanding their features is essential for optimal results.

Die pick up tools and collets come in various types and sizes. Each type serves a specific purpose. For instance, collets hold tools securely, while pick up tools help in easy retrieval and adjustment. Misunderstanding these tools can lead to project delays.

Consider the materials and designs that suit your work. High-quality options may come at a higher cost. However, investing in reliable tools often pays off. Ensuring compatibility with your setup is also vital. Take the time to research and reflect on your needs. This will significantly improve your project outcomes.

Die pick up tools play a crucial role in manufacturing. These tools directly impact the precision and efficiency of production processes. According to a recent industry report, approximately 70% of companies reported that using advanced die pick up tools increased their overall manufacturing efficiency by over 20%. This highlights the importance of choosing the right tools for your specific projects.

In addition to efficiency, the quality of die pick up tools affects the final product's quality. Some reports suggest that about 30% of manufacturing defects can be traced back to inadequate tool selection. Poor performance can result in additional costs and delays. Manufacturers must evaluate their specific needs carefully when selecting collets and pick up tools. It's not just about availability but also about compatibility with the existing machinery.

Many manufacturers overlook these factors. They often choose based on price rather than quality or performance. It's essential to consider the long-term effects of these decisions. Investing in reliable tools may seem costly upfront but could save money and time in the long run. A careful approach can lead to better productivity and, ultimately, superior products.

When selecting die pick up tools, understanding their types and applications is crucial. Traditionally, there are three main types: hand tools, electric tools, and pneumatic tools. Hand tools include manual picks and tweezers, suitable for small tasks. They provide excellent control but can be tiring for larger projects. Electric tools are faster and more efficient. They are ideal for larger volumes of work but require a power source. Pneumatic tools are powerful and suited for heavy-duty applications but can be cumbersome and more expensive.

Tips: Always consider the size of your project. If it's small, choose hand tools for precision. For larger projects, electric tools save time. Remember, the right tool enhances productivity.

Another important aspect is the collet selection. Collets grip the dies firmly, ensuring accuracy. Look for collets made from durable materials that can withstand pressure. Some collets offer quick-change capabilities, which significantly reduce downtime. However, they may require more frequent adjustments.

Tips: Test different collets to find the perfect fit. Consider the weight and size of the dies you are using. Proper grip is critical for successful outcomes.

Selecting the right collets for your projects is crucial. Key specifications can greatly affect your work's precision and efficiency. Consider the collet type first. There are various types, including ER, 5C, and R8, each serving different applications. According to industry reports, using the proper collet can increase tool retention by up to 30%, which directly impacts machining accuracy.

Next, pay attention to the collet's material. Typically, high-carbon steel or stainless steel are used. These materials offer strength and durability. Inappropriate materials may lead to premature wear. The size range is another vital specification. Ensure the collet can accommodate the tools you plan to use. A mismatch here can cause issues like tool slippage.

Lastly, think about the collet's clamping force. Too much force can damage your tools while too little can compromise your work quality. A well-calibrated collet not only secures the tool but also enhances the machining process. Small errors in selection can lead to significant setbacks. Always review your choices to avoid pitfalls in your project efforts.

When selecting die pick up tools, material choice is critical. Various materials offer distinct performance characteristics. For instance, steel tools often provide durability but can lack some flexibility. On the other hand, materials like aluminum are lightweight but might wear down more quickly. A report by the Industry Research Center highlighted that tools made from high-speed steel (HSS) exhibit a 30% longer lifespan compared to standard steel options.

In contrast, there are also composite materials that blend properties of metals and plastics. These can offer a balance of strength and weight. However, their performance can vary significantly based on their composition and manufacturing process. For example, a study from the Manufacturing Technology Review indicated that some composites can resist deformation under higher loads better than traditional materials, providing more reliable results during usage.

One common issue is the choice made based on initial cost rather than long-term value. Many buyers overlook that while cheaper options seem appealing, they may require more frequent replacements. In fact, using higher-quality materials can lead to a decrease in overall project costs due to prolonged tool life. Decisions made in material selection reveal a lot about project priorities and the importance of evaluating both immediate benefits and long-term results.

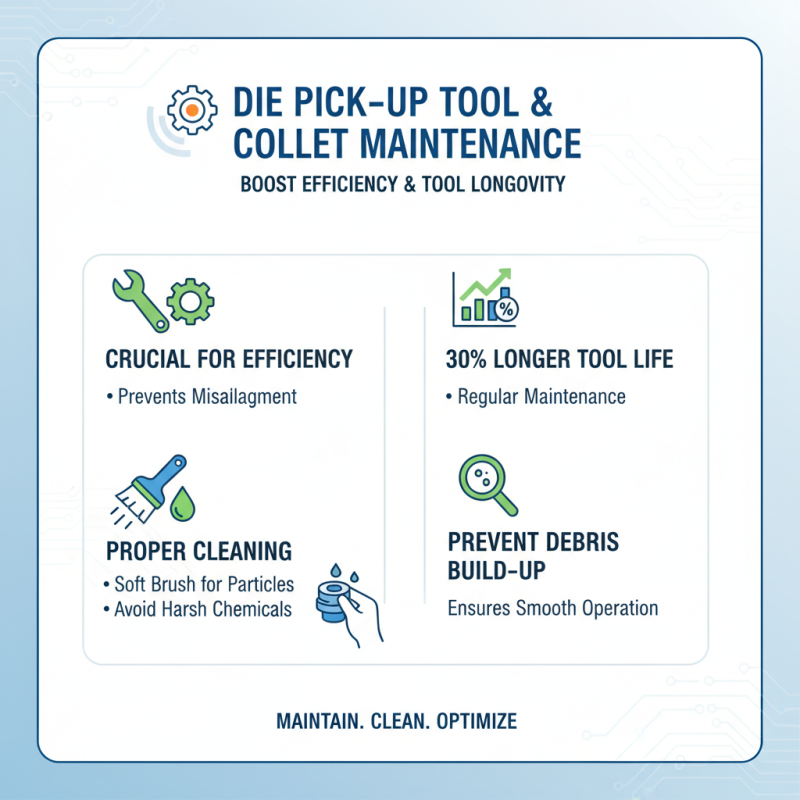

Maintaining die pick up tools and collets is crucial for efficiency. Regular maintenance can lead to a 30% increase in tool lifespan. Proper cleaning is essential. Accumulated debris can cause misalignment during operation. Use a soft brush to remove particles. Avoid harsh chemicals that can damage surfaces.

Inspecting collets regularly is vital. A small crack can lead to tool failure. Replace collets every 6 to 12 months, depending on usage. Greasing moving parts is important too. Under-lubricated components can increase wear rates by 20%. Always check for corrosion and rust. A visual inspection takes just minutes but can save costly repairs.

Training staff on maintenance is often overlooked. It can reduce errors significantly. A 2019 industry report indicated that 25% of tool failures result from improper handling. Engage team members in preventive practices. It fosters a culture of care. Enhanced vigilance can lead to higher productivity.