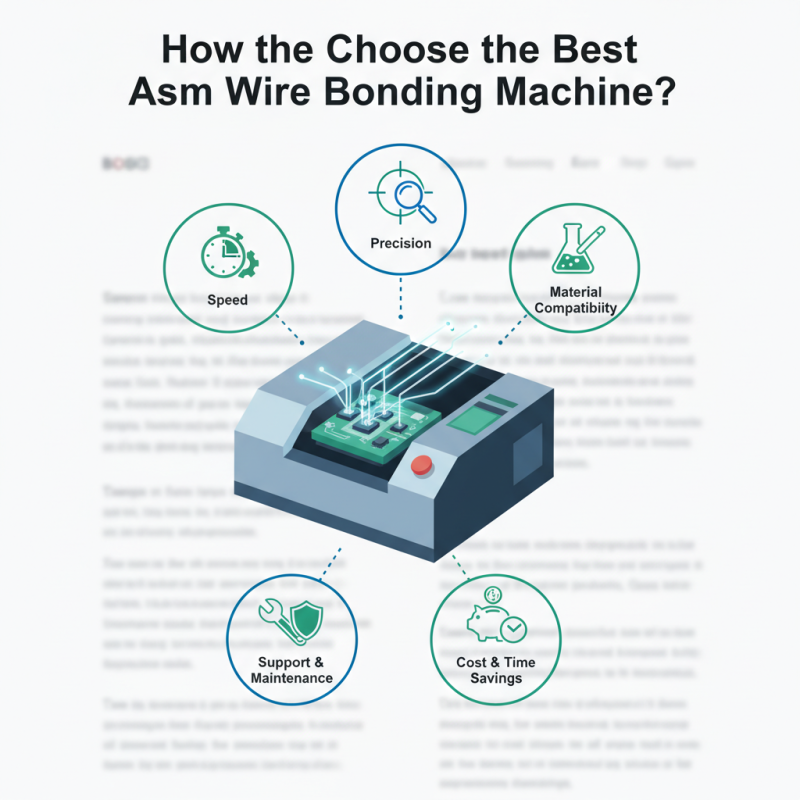

Choosing the right Asm Wire Bonding Machine is crucial for efficiency in electronic manufacturing. This machine plays a significant role in the assembly process. Its effectiveness impacts product reliability and overall quality.

When selecting an Asm Wire Bonding Machine, it’s essential to consider various specifications. Speed, precision, and material compatibility are vital. Many manufacturers focus solely on speed, overlooking precision. This can lead to costly errors.

Another factor to think about is support and maintenance. Machines may require occasional repairs or updates. If the manufacturer lacks a solid support system, you might face challenges later. Reflecting on these aspects can help in making a well-informed choice. The right selection saves time and resources in the production process.

When selecting an ASM wire bonding machine, it is crucial to understand the fundamentals behind their operation. Wire bonding is a method used to connect semiconductor chips to their packaging. This process requires precision and consistency. The choice of machine affects product quality and overall efficiency.

Tips: Consider the machine's bonding speed and accuracy. Faster machines might seem appealing, but they can compromise on precision. A balance between these aspects is essential. Also, explore the machine's adaptability to different wire types. Not all projects require the same materials.

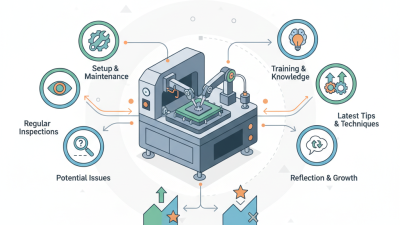

Machine features matter. Look for easy maintenance options. Complex machines may lead to long downtimes. Simplicity in operation often translates to lower operational errors. Users should reflect on their team’s skill level when selecting machinery. A complex machine may confuse operators, leading to mistakes. Aim for a user-friendly interface.

Evaluating these factors will guide a more informed decision. Seek machines that can grow with your needs. The right choice can significantly impact production workflows.

This chart compares the performance metrics of various wire bonding machines in terms of speed, precision, and cost. Understanding these fundamentals will guide you in selecting the best ASM wire bonding machine for your needs.

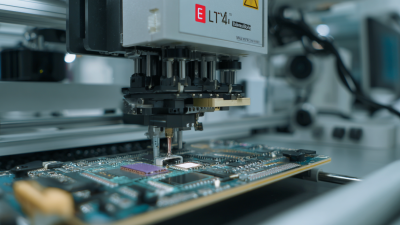

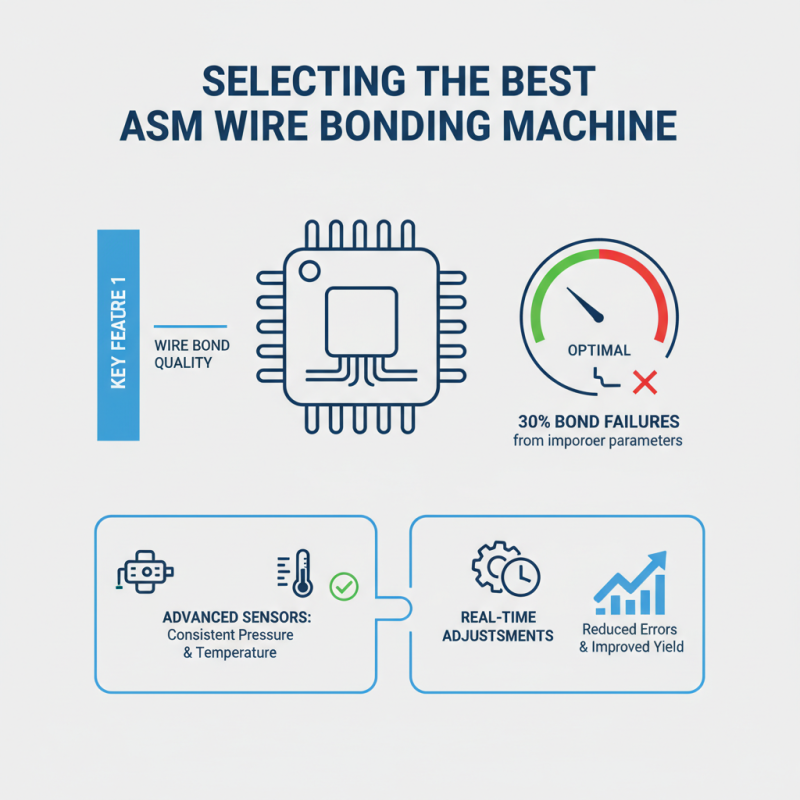

When selecting the best ASM wire bonding machine, it's crucial to evaluate key features. One significant feature is the wire bond quality. According to industry reports, nearly 30% of bond failures are due to improper bonding parameters. Look for machines with advanced sensors that ensure consistent pressure and temperature during the bonding process. The ability to adjust bond parameters in real time can reduce errors and improve yield rates.

Another important aspect is the machine’s versatility. Many applications now require different wire types and sizes. A report from a leading semiconductor research firm indicates that machines with multi-mode capabilities can handle various wire configurations. This adaptability not only saves time but also reduces the need for multiple machines in production lines. However, it is essential to assess whether the added complexity offers tangible benefits.

Lastly, consider the automation features. Automation can increase efficiency but may also lead to reliance on technology. According to recent studies, 40% of operators struggle with fully automated systems due to programming complexities. Balancing automation with operator skill is vital. Finding a machine that enhances productivity without overwhelming users can often be challenging. This balance is where many companies need to reflect on their choices.

When selecting a wire bonding machine, it's crucial to compare the technologies available. Each technology has distinct advantages. For instance, ultrasonic wire bonding delivers strong bonds with minimal thermal damage. On the other hand, thermosonic bonding combines heat and ultrasonic waves, enhancing bond reliability. Understanding these differences can lead to better decisions.

Tip: Always assess the material compatibility of the bonding method. Some materials react differently to heat or sound. If you’re uncertain, consult with experts.

Another significant consideration is the machine's ease of operation. Complex interfaces can lead to errors. Simpler controls may improve productivity. Look for machines with user-friendly designs. They save time and reduce learning curves.

Tip: Consider automation options. While they may cost more upfront, they can enhance efficiency long term. Evaluate if the current setup can adapt to automated solutions easily.

In the end, a well-informed choice matters. Reflect on your production needs and the potential growth of your projects. It may take time to find the perfect fit. Be patient and thorough in your research.

| Technology | Bonding Type | Wire Diameter (μm) | Cycle Time (ms) | Application |

|---|---|---|---|---|

| Ultrasonic Bonding | Ball Bonding | 15 - 50 | 100 - 200 | Microelectronics |

| Thermosonic Bonding | Ball Bonding | 15 - 25 | 80 - 150 | RFID, MEMS |

| Wedge Bonding | Wedge Bonding | 25 - 75 | 120 - 240 | Power Devices |

| Laser Bonding | Ball Bonding | 20 - 50 | 150 - 300 | High-Power Applications |

| Gold Wire Bonding | Ball/Wedge Bonding | 12 - 30 | 100 - 250 | High-Precision Devices |

When assessing wire bonding equipment, the cost-benefit ratio is key. A detailed analysis reveals that quality machines can range from $50,000 to over $250,000. Factors affecting these costs include speed, accuracy, and long-term reliability. In a recent industry report, up to 22% of production costs can be related to inferior bonding processes. Investing wisely can lead to substantial savings and increased efficiency.

Tips: Always analyze your production volume. A higher upfront cost can be justified with increased throughput. Look for machines that offer dual modes: manual and automatic. This flexibility can optimize both small and large runs effectively.

Not all machines offer the same return on investment. Some may cost less, but they could lead to higher scrap rates. A machine with a 95% yield is far better than one at 80%. Over time, these differences compound. It's essential to weigh initial costs against potential long-term savings. Therefore, consider total cost assessments, including maintenance and potential downtime.

The wire bonding machine market has seen significant growth in recent years. A report from TechNavio reveals that this market is expected to grow by over 5% annually until 2025. Demand is driven by the increasing need for compact electronic devices and advanced semiconductor packaging. Manufacturers are focusing on boosting production efficiency and improving quality.

Top manufacturers specialize in various bonding technologies. Their machines vary in speed, precision, and functionality. The choice may depend on specific application requirements. For instance, some machines excel in thermosonic wire bonding, while others specialize in ultrasonic bonding. Each process has distinct advantages and limitations.

Market analysis shows that innovation is crucial. Some manufacturers struggle to keep pace with technological advancements. This often leads to a gap in product reliability and performance. Failing to adapt could result in missed opportunities. Investing in the wrong equipment might also hinder production efficiency. Balancing cost with quality becomes essential for manufacturers navigating this competitive landscape.