In the fast-evolving world of electronics, the Wire Bonding Machine stands as a crucial tool. These machines connect semiconductor chips to their packaging. Reliability is key to ensuring optimal performance. As demand grows for advanced technology, the need for high-quality wire bonding solutions intensifies.

The 2026 market promises significant advancements in wire bonding technology. However, not all machines meet the rigorous standards required. It is essential to evaluate performance, speed, and versatility. Users must consider machine specifications and real-world reliability. The success of a device largely depends on the quality of its wire bonding process.

While many choices exist, finding the best machine can be challenging. It's important to reflect on individual needs and factory conditions. Some machines may not perform well under all circumstances. An imperfect machine can lead to costly failures. Therefore, careful analysis ensures a better decision. Embracing innovation while scrutinizing flaws is vital in this journey.

Wire bonding technology plays a crucial role in modern manufacturing. It connects semiconductor chips to their packages, ensuring reliable performance. A bond that fails can lead to significant issues. Therefore, understanding the technology behind this process is essential.

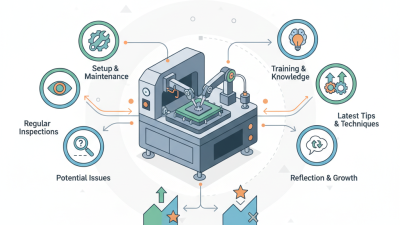

Choosing the right equipment impacts production quality. A good wire bonding machine can enhance efficiency. However, it also requires regular maintenance. Neglecting upkeep can result in more breakdowns and costly delays. Inadequate training for operators can further exacerbate these problems. Proper training ensures that operators understand the machine’s complexities.

Manufacturers must continuously evaluate their wire bonding processes. Sometimes, outdated methods linger longer than they should. New techniques can offer better performance and reliability. Yet, implementing changes can be challenging. Resistance to new technologies may arise. Addressing these issues requires open communication and ongoing education in the workforce.

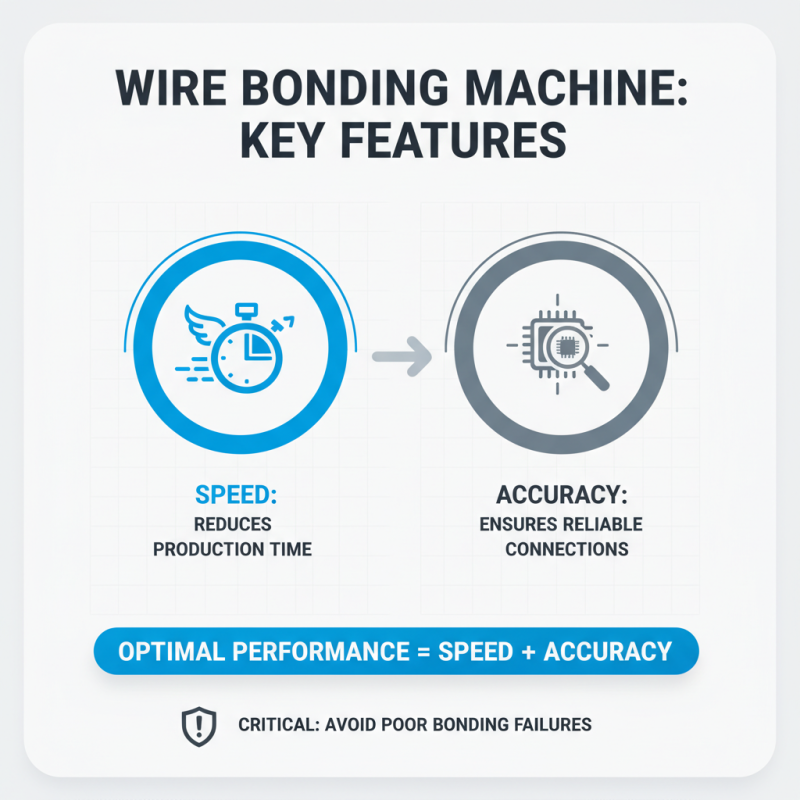

When selecting a wire bonding machine, certain key features can greatly enhance performance. Speed and accuracy top the list. A machine that can operate quickly reduces production time. Yet, it’s vital that speed does not compromise precision. After all, poor bonding can lead to failures. Precision is critical in ensuring reliable connections in electronic devices.

Temperature control is another essential feature. Consistent temperature helps maintain bonding quality. Machines with adjustable settings cater to different materials. This flexibility can be invaluable during production adjustments. Moreover, intuitive user interfaces streamline operations. An easy-to-navigate control panel reduces training time for operators. However, overly complicated systems can hinder quick troubleshooting.

Lastly, durability and maintenance are worth considering. A sturdy build ensures longevity, yet some machines may require frequent repairs. Routine maintenance can be tedious but is essential for optimal performance. It’s important to find a balance between robustness and maintenance needs. Investing in a machine that balances these aspects can yield better productivity and reliability in the long run.

The wire bonding machine market is evolving rapidly. According to industry analyses, the global market is expected to reach $1.8 billion by 2026. This growth is driven by the rising demand for efficient bonding solutions in semiconductor manufacturing.

In 2026, key players in the wire bonding machine market will focus on improving reliability and performance. Advances in technology are pushing for greater precision in bonding processes. However, many manufacturers still face challenges in achieving consistent quality. Variability in wire materials can lead to defective bonds. This issue is critical as it can affect overall production yield.

Energy-efficient designs are becoming a priority as well. Reports indicate that machines that minimize energy consumption are gaining traction. Still, some companies struggle to balance cost and performance. Investing in state-of-the-art technology can be costly. Yet, those who adapt may see long-term benefits. The market will continue to fluctuate as new technologies emerge. Manufacturers will need to stay agile and responsive to succeed.

| Machine Model | Max Bonding Speed (Bonds/sec) | Bonding Type | Yield Rate (%) | Price Range (USD) |

|---|---|---|---|---|

| Model A | 300 | Ultrasonic | 98 | $15,000 - $20,000 |

| Model B | 250 | Thermosonic | 95 | $12,000 - $18,000 |

| Model C | 200 | Wedge | 97 | $10,000 - $15,000 |

| Model D | 350 | Ball | 99 | $20,000 - $25,000 |

When evaluating wire bonding machines, examining performance metrics is essential. These machines serve critical roles in electronics manufacturing. Factors such as speed, accuracy, and reliability play significant roles in choosing the right equipment. Advanced bonding techniques can improve overall performance, but they may also increase complexity.

Tips: Always consider the specific requirements of your project. Performance metrics may vary significantly based on the application. Focus on machines that demonstrate consistent reliability in various conditions.

Another important metric is ease of use. Some machines come with user-friendly interfaces, while others may require extensive training. This can influence your production schedule. The balance between advanced features and usability should be carefully assessed.

Tips: Pay attention to customer support and training options. A well-supported machine can save time and enhance productivity. Reflect on the operation environment. It’s crucial to select a machine that fits seamlessly into your existing setup.

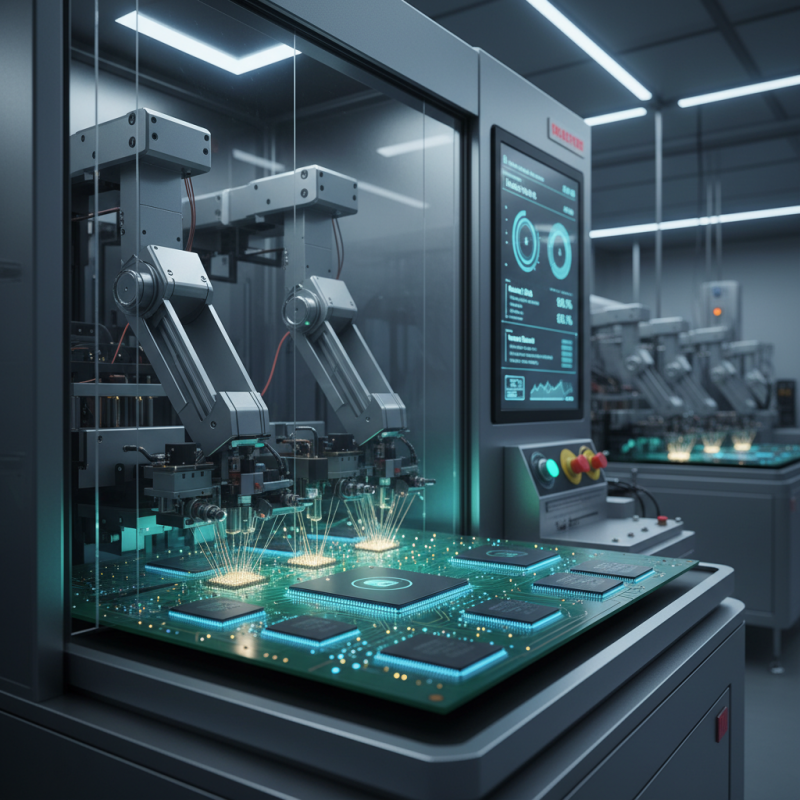

The wire bonding machine market is evolving at a rapid pace. Innovations are driving efficiency and accuracy. Future designs may incorporate advanced automation, making the bonding process smoother. With robotics, the precision of wire placement can significantly improve. This will lead to higher quality outputs. However, challenges remain.

Some machines struggle with varying materials. Different wire types can affect performance. Manufacturers will need to address these inconsistencies. Another area for innovation is software integration. Enhanced software can provide real-time monitoring. This can help detect issues early and guide operators. Yet, systems may sometimes be too complex, leading to user errors. Designers must ensure that machines are user-friendly while still being highly functional.

Sustainability is becoming important too. Future machines should consider energy efficiency. This could help reduce operational costs. However, using eco-friendly materials may complicate the manufacturing process. Balancing performance and environmental impact will be crucial for future developments in wire bonding technology. Each step forward must reflect on these intricate challenges.