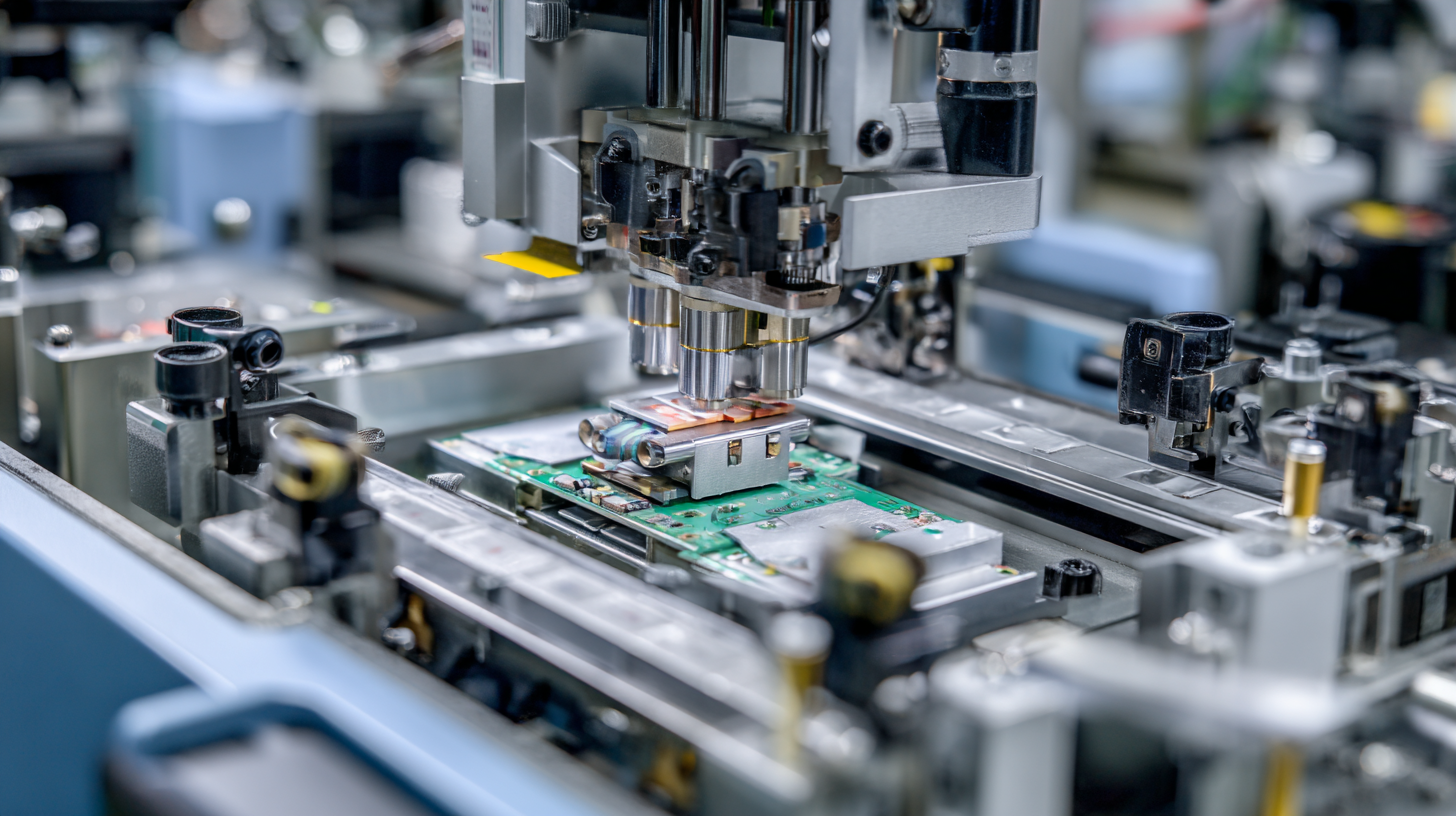

In the fast-paced world of high-volume production, selecting the right equipment can significantly impact efficiency and quality. Among the myriad of tools essential for semiconductor and electronic assembly, wire bonders stand out as critical devices that ensure reliable connections in integrated circuits. As we step into 2023, the advancements in wire bonding technology have led to a plethora of options in the market, making the decision on which wire bonder to choose more challenging yet crucial for manufacturers aiming to enhance their production capabilities. This blog will guide you through the key considerations and features to evaluate when selecting the best wire bonders for your high-volume production needs, ensuring you make an informed choice that aligns with your operational goals and technological requirements.

When selecting wire bonders for high-volume production in 2023, several key features must be considered to ensure optimal performance and efficiency. The advancements in semiconductor manufacturing technology, including innovations in hybrid bonding and enhanced inspection solutions, underscore the importance of selecting wire bonders that align with the latest industry standards. To address the increasing complexity of packaging, manufacturers should prioritize bonders that support advanced processes, such as TCB (Thermal Compression Bonding) and other hybrid bonding techniques, which are projected to significantly expand the market, reaching approximately $1.3 billion by 2030.

Moreover, the importance of precision in wire bonding cannot be overstated. Recent developments in inspection technologies have introduced solutions that utilize advanced capacitive structures to accurately evaluate bond quality. With the semiconductor manufacturing equipment market anticipated to grow to $109.24 billion in 2024, choosing the right wire bonder must also consider factors such as integration capabilities with modern inspection systems, which can enhance production efficiency and yield. Ultimately, adapting to the evolving demands of the semiconductor landscape will ensure that manufacturers can remain competitive in high-volume production environments.

This chart illustrates the performance ratings of key features to consider when selecting wire bonders for high volume production in 2023. Higher ratings indicate better performance in each feature category, helping you make an informed choice for optimal production efficiency.

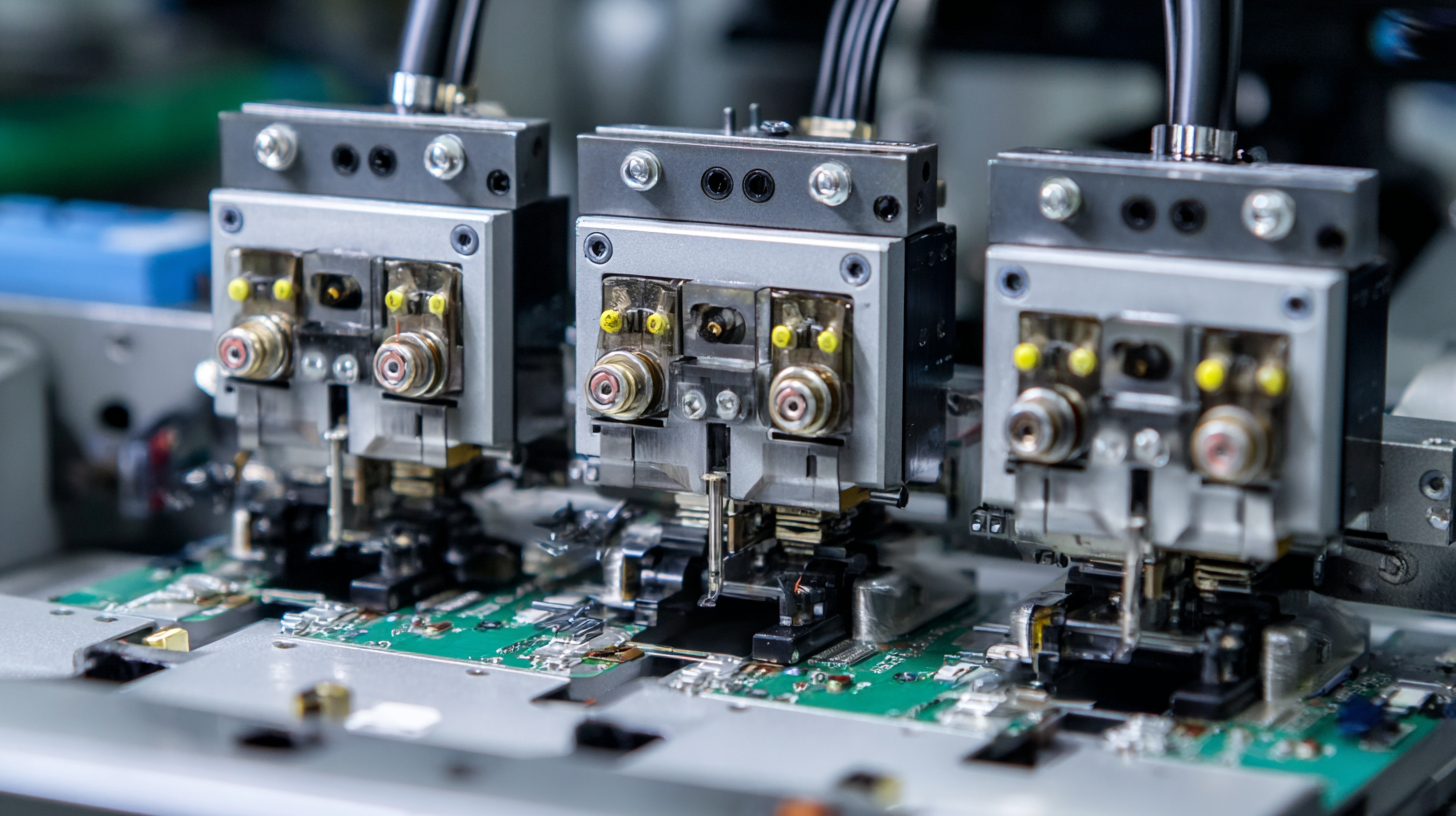

When selecting wire bonders for high-volume production, understanding

the different types available and their specific applications is crucial. Wire bonders typically fall into two

main categories: manual and automated systems.

Manual wire bonders provide flexibility and are suitable for low-volume or prototyping scenarios.

In contrast, automated wire bonders are designed for high-speed production

lines and can significantly enhance throughput. As the demand for semiconductor devices continues to grow,

so does the need for efficient and reliable wire bonding solutions.

Manual wire bonders provide flexibility and are suitable for low-volume or prototyping scenarios.

In contrast, automated wire bonders are designed for high-speed production

lines and can significantly enhance throughput. As the demand for semiconductor devices continues to grow,

so does the need for efficient and reliable wire bonding solutions.

The wire bonding market is projected to see substantial growth in the coming years, with estimates suggesting a reach of USD 7.82 billion by 2034. This growth is driven by advancements in technology, including the development of new bonding methods and improvements in existing materials. Additionally, various applications such as consumer electronics, automotive components, and telecommunications are pushing the boundaries of wire bonding technology. Understanding these applications helps manufacturers choose the right type of wire bonder that aligns with their production needs, ensuring both efficiency and quality in their processes.

When selecting wire bonders for high-volume production, evaluating their performance metrics is crucial. Speed is often the first parameter to consider, as faster bonding can significantly boost production efficiency. The capabilities of the bonder should align with your production demands; look for machines that offer rapid bonding cycles without compromising the quality of the bond. The specified cycle time should cater to your throughput requirements, while automation features can further enhance productivity.

Accuracy is another essential factor that directly impacts the reliability of your products. In the world of microelectronics, precision in wire bonding ensures optimal electrical and thermal performance. Check for bond strength specifications and consider machines that provide real-time monitoring and correction features. Additionally, ensure that the bonder can handle the specific materials and sizes of wires you require, as this will play a vital role in maintaining consistent manufacturing quality.

Reliability is the third performance metric to prioritize. High-volume production demands equipment that can withstand rigorous operation without frequent failures. Investigate vendors' histories regarding uptime and maintenance requirements, and seek models known for their durability. It's advisable to explore customer reviews and warranty offerings, as these can provide insight into the long-term performance of the wire bonders you are considering.

When investing in wire bonders for high volume production, balancing cost and quality is critical. A lower price point might be tempting, but it can lead to hidden costs in the long run, such as increased maintenance and downtimes due to inferior performance. It’s essential to consider not just the initial purchase price but the total cost of ownership, which includes factors like reliability, support services, and the longevity of the equipment. Investing in quality equipment may pave the way for higher efficiency and less waste during production.

On the other hand, choosing the most expensive option isn't always a guarantee of top performance. Evaluating the specifications and capabilities of each wire bonder is crucial. Look for models that offer optimal features aligned with your production needs, whether it’s speed, precision, or the ability to handle various materials. Additionally, assess the manufacturer's reputation and customer support, as these can significantly affect the performance of your investment—ensuring that your production line remains efficient and effective over time. Balancing these factors is key to making an informed decision that supports both your budget and production goals.

In 2023, the landscape of wire bonding technology is evolving rapidly, driven by the demand for enhanced production efficiency in high volume settings. One of the key trends is the integration of automation and artificial intelligence into wire bonding systems. These technologies not only streamline the bonding processes but also improve precision and consistency, ensuring higher yield rates and reduced operational costs.

When selecting wire bonders, consider the machine's adaptability to future technologies. Look for models that support modular upgrades, allowing adjustments as needs evolve. Additionally, evaluate the compatibility with Industry 4.0 frameworks, which enable machines to communicate data in real-time, facilitating predictive maintenance and reducing downtime.

Another important trend is the increased focus on eco-friendly materials and processes. As sustainability becomes a priority, choosing wire bonders that utilize greener bonding materials can significantly impact your production's environmental footprint. Look for systems that boast energy-efficient operations and minimal waste production, which align with both regulatory requirements and corporate sustainability goals.

| Feature | Description | Future Trends | Efficiency Impact |

|---|---|---|---|

| Automation | Increased automation in wire bonding processes. | Integration of AI and robotics for enhanced automation. | Higher throughput and reduced labor costs. |

| Material Innovation | Use of advanced materials for wire bonding. | Development of next-gen bonding wires. | Improved reliability and performance. |

| Speed | Faster bonding cycles through improved techniques. | Emergence of high-speed wire bonders. | Significantly increased production output. |

| Quality Control | Enhanced monitoring systems for quality assurance. | Real-time data analytics for quality control. | Reduction in defects and rework rates. |

| Flexibility | Adaptation to a range of product types. | Modular designs for diverse applications. | Improved compatibility with various production lines. |