In today's rapidly evolving semiconductor industry, the demand for reliable and high-quality wire bonding equipment has never been greater. The Westbond Wire Bonder, manufactured by China's leading production enterprises, stands out as a prime solution for achieving unmatched bonding precision and efficiency. According to a recent report by Allied Market Research, the global wire bonding market is projected to reach $4.2 billion by 2027, with a compound annual growth rate (CAGR) of 5.1% from 2020 to 2027. This growth underscores the necessity for advanced wire bonders that not only deliver superior performance but also offer exceptional after-sales service and lower maintenance costs. By choosing Westbond Wire Bonder, businesses can leverage these services and achieve cost-effective operations, ultimately enhancing their profitability and competitiveness in the market.

In today's fast-evolving technology landscape, the need for innovative solutions in wire bonding has never been more apparent. Westbond, a prominent manufacturer in the industry, has made significant strides in offering alternatives to traditional wire bonders. Their innovative designs focus on enhancing efficiency while reducing waste, aligning with the growing need for sustainability across various manufacturing sectors.

As industries like pulp and paper undergo transformation to mitigate climate impacts, Westbond's approach to wire bonding can play a vital role. By integrating advanced technologies, manufacturers can optimize their production processes, leading to reduced emissions and a minimized environmental footprint. This is especially relevant in sectors where traditional methods have been less eco-friendly.

Tips for manufacturers include: First, consider implementing automated systems that align with advanced semiconductor packaging techniques, allowing for greater precision and reduced error rates. Second, stay informed about emerging technologies and processes that can streamline production while adhering to environmental standards. By adopting these methods, businesses not only enhance their operational efficiency but also contribute to a more sustainable future.

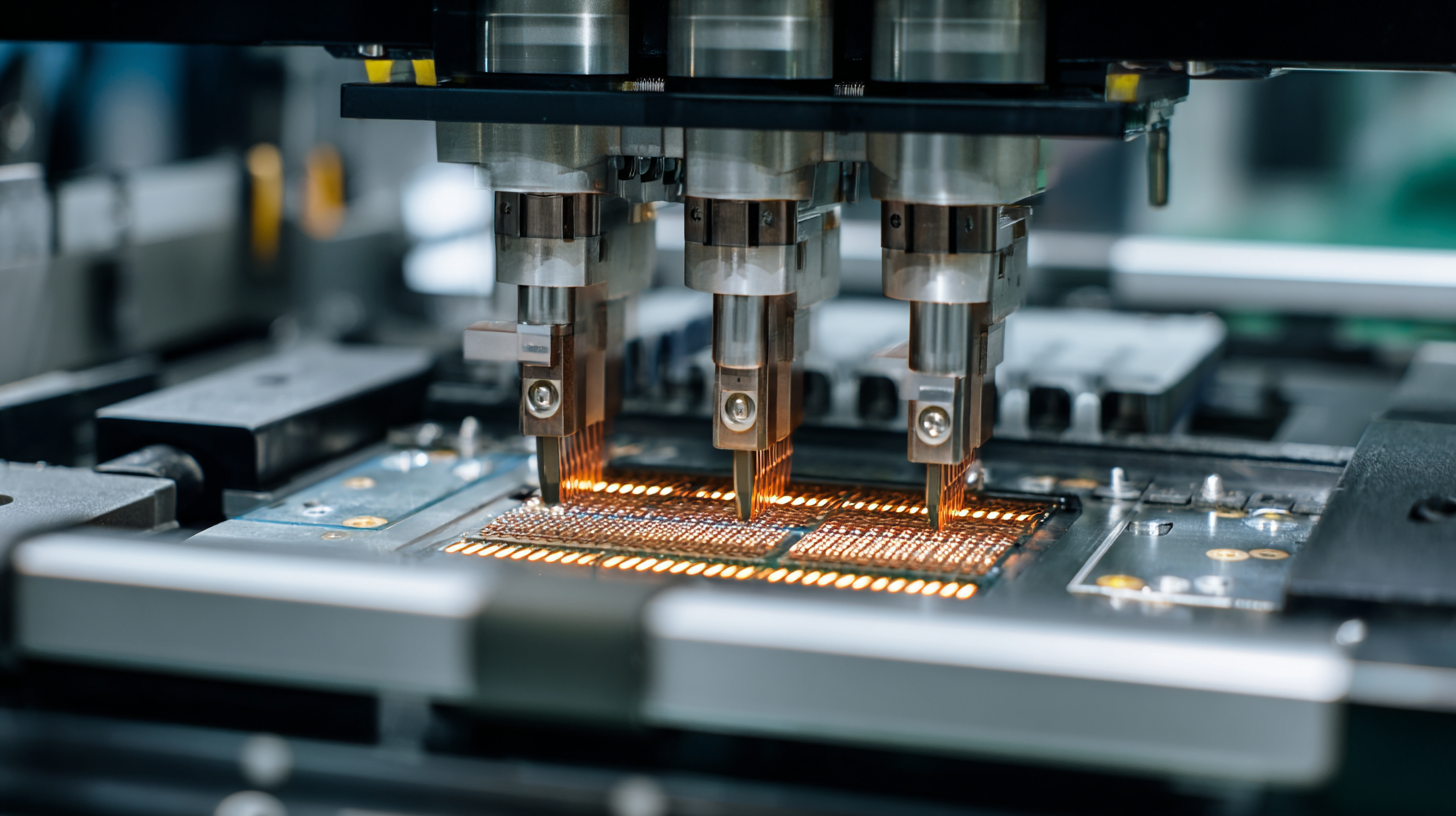

When it comes to wire bonding in the semiconductor industry, Westbond stands out as a premier choice, thanks to its innovative designs and exceptional manufacturing processes. One of the key features that set Westbond wire bonders apart is their advanced bonding technology, which ensures consistent, high-quality connections. This technology minimizes the risk of bond failures and provides greater reliability in high-performance applications. With precision engineering, Westbond wire bonders can handle a variety of wire types and materials, catering to diverse needs in the manufacturing sector.

When it comes to wire bonding in the semiconductor industry, Westbond stands out as a premier choice, thanks to its innovative designs and exceptional manufacturing processes. One of the key features that set Westbond wire bonders apart is their advanced bonding technology, which ensures consistent, high-quality connections. This technology minimizes the risk of bond failures and provides greater reliability in high-performance applications. With precision engineering, Westbond wire bonders can handle a variety of wire types and materials, catering to diverse needs in the manufacturing sector.

Another distinguishing factor of Westbond wire bonders is their user-friendly interface and automation capabilities. Operators can quickly adapt to the system, significantly reducing training time and improving overall efficiency. This user-centric design not only enhances productivity but also integrates seamlessly with existing production lines. Additionally, Westbond offers custom solutions tailored to specific customer requirements, reinforcing their commitment to quality and service. Together, these features make Westbond’s wire bonders an unparalleled choice for businesses seeking reliability and performance in their manufacturing processes.

The Westbond Wire Bonder has emerged as a game-changer in the realm of microelectronic assembly, especially considering its affordability coupled with exceptional quality. As industries continually seek to optimize their manufacturing processes, the economic advantages of utilizing Westbond products cannot be overstated. These machines provide robust performance and reliability, reducing operational downtime and maintenance costs. This efficiency not only enhances productivity but also contributes to a significant return on investment for businesses of all sizes.

Moreover, the value of the Westbond Wire Bonder lies in its technology and precision engineering. Designed by China’s premier manufacturer, these bonders utilize advanced features that streamline workflows while maintaining a high standard of output. By incorporating state-of-the-art technology and materials into their construction, Westbond ensures that users receive a product that stands up to rigorous demands without breaking the bank. For companies looking to balance cost and quality in their production lines, the Westbond Wire Bonder represents an intelligent investment that guarantees long-term benefits in performance and reliability.

Discover how Westbond wire bonders have transformed the manufacturing landscape through real-world applications. Customers across various industries have reported remarkable improvements in efficiency and reliability after incorporating Westbond technology into their production processes. From semiconductor packaging to medical device assembly, these bonders have proven essential in delivering unmatched quality, ensuring products meet the highest standards.

Discover how Westbond wire bonders have transformed the manufacturing landscape through real-world applications. Customers across various industries have reported remarkable improvements in efficiency and reliability after incorporating Westbond technology into their production processes. From semiconductor packaging to medical device assembly, these bonders have proven essential in delivering unmatched quality, ensuring products meet the highest standards.

One success story involves a leading semiconductor company that experienced a 30% increase in production output after integrating Westbond wire bonders. By leveraging advanced automation features, they reduced manual errors and improved precision, leading to higher yields and lower costs. Another customer in the medical field highlighted reduced lead times, enabling them to bring life-saving products to market faster.

Tip: When selecting a wire bonder, consider the specific needs of your application. Evaluate parameters like bond quality, speed, and compatibility with materials to ensure you choose the right equipment.

Tip: Ensure proper training for your operators on the Westbond technology to maximize its capabilities. A well-informed team can handle advanced features, leading to more efficient production processes and better overall results.

The wire bonding industry is on the cusp of significant transformation as technology evolves. With Westbond leading the charge, we can expect innovations that enhance efficiency and precision. The introduction of advanced materials and automation will streamline the bonding process, reducing production times and costs while improving the reliability of connections. As manufacturers explore nano-scale applications, the demand for high-quality bonding solutions will escalate, placing Westbond at the forefront of these developments.

Moreover, sustainability is becoming a critical focus within the wire bonding sector. Westbond is actively integrating eco-friendly practices in their manufacturing processes, aligning with global trends towards greener technology. As the industry adapts to these changes, customers will be able to benefit from products that not only meet high-performance standards but also adhere to environmental regulations. The next few years promise exciting advancements in wire bonding, making it an ideal time for organizations to partner with reputable manufacturers like Westbond.

This chart illustrates the projected market growth percentage for the wire bonding industry from 2021 to 2025. It reflects the continuous demand and technological advancements that are expected to drive growth in this sector.