In the rapidly advancing semiconductor industry, efficiency and performance are paramount, making the choice of tools critical for success. The

Kns Wire Bonder has emerged as a frontrunner in this landscape, recognized for its potential to enhance device performance and reliability. According to a report by

MarketsandMarkets, the wire bonding equipment market is expected to grow from $3.2 billion in 2023 to

$4.5 billion by 2028, reflecting an increasing demand for high-precision assembly tools that the

Kns Wire Bonder epitomizes. With its advanced technical specifications, this wire bonder not only meets but often exceeds the rigorous demands of modern semiconductor manufacturing,

ensuring optimal connections critical for device functionality. By unlocking the potential of the

Kns Wire Bonder, manufacturers can significantly enhance their production efficiency, driving innovation and

competitiveness in an industry characterized by continuous technological evolution.

In the rapidly advancing semiconductor industry, efficiency and performance are paramount, making the choice of tools critical for success. The

Kns Wire Bonder has emerged as a frontrunner in this landscape, recognized for its potential to enhance device performance and reliability. According to a report by

MarketsandMarkets, the wire bonding equipment market is expected to grow from $3.2 billion in 2023 to

$4.5 billion by 2028, reflecting an increasing demand for high-precision assembly tools that the

Kns Wire Bonder epitomizes. With its advanced technical specifications, this wire bonder not only meets but often exceeds the rigorous demands of modern semiconductor manufacturing,

ensuring optimal connections critical for device functionality. By unlocking the potential of the

Kns Wire Bonder, manufacturers can significantly enhance their production efficiency, driving innovation and

competitiveness in an industry characterized by continuous technological evolution.

As the semiconductor industry continues to evolve, the demand for more efficient and reliable wire bonding processes takes center stage. The choice of a Kns wire bonder can significantly impact the performance of semiconductor devices, especially in the face of emerging technologies in 2025. When selecting the right wire bonder, key features such as precision, speed, and adaptability to different materials become critical considerations.

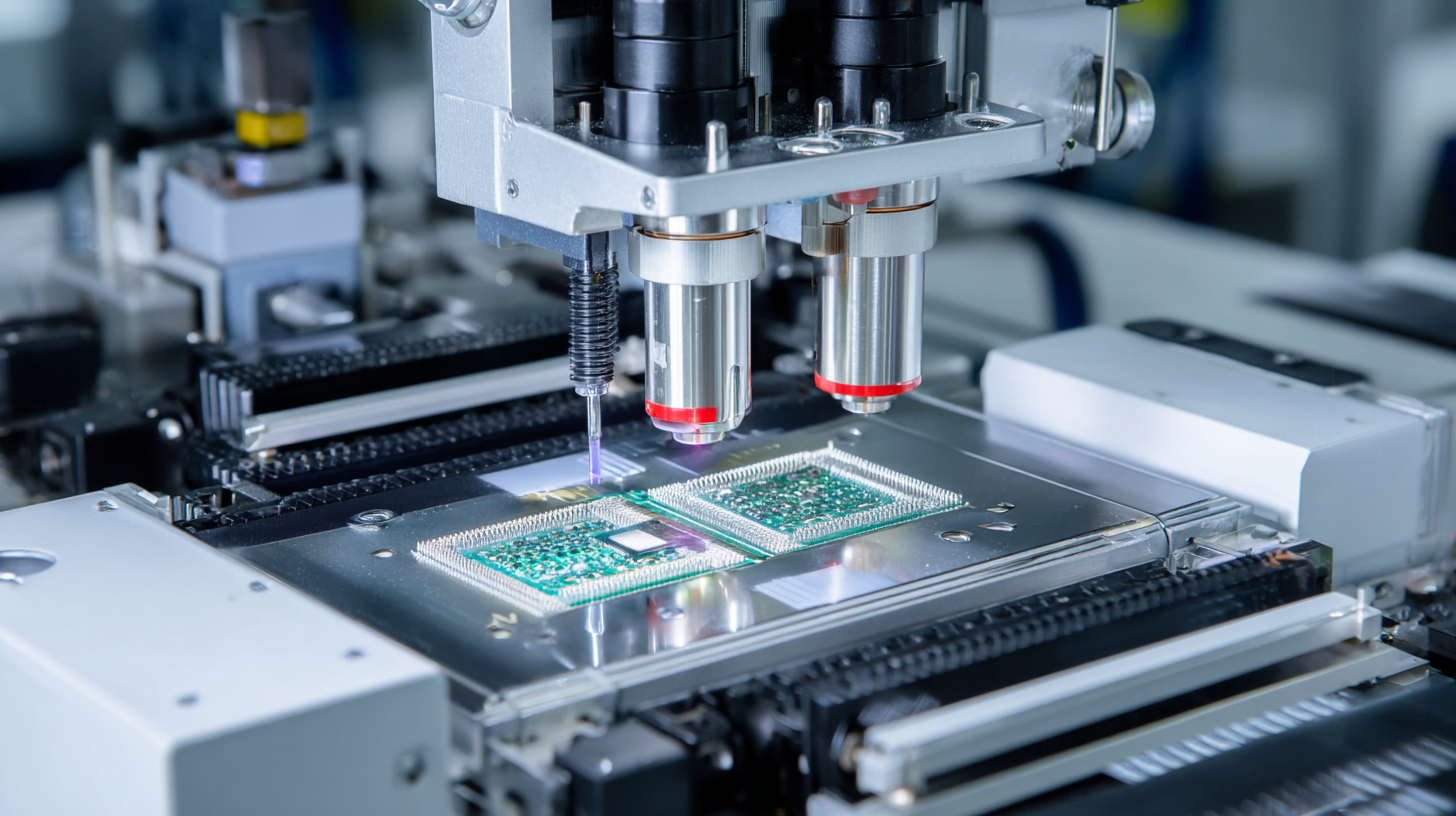

Precision is paramount in wire bonding to ensure minimal defects and high yield rates. The best Kns wire bonders incorporate advanced imaging systems that allow for real-time monitoring and adjustments during the bonding process. Additionally, speed is essential for meeting the increasing production demands; thus, models that integrate automation and high-speed bonding capabilities provide a competitive edge. Furthermore, compatibility with a range of wire and substrate materials will enable manufacturers to innovate and experiment with new designs, ensuring their processes remain at the forefront of semiconductor technology.

As we look towards future innovations, investing in a Kns wire bonder that combines these features will be pivotal in unlocking new levels of efficiency and performance in semiconductor manufacturing. Understanding these key elements will guide manufacturers in making informed choices that align with the fast-paced advancements in the industry.

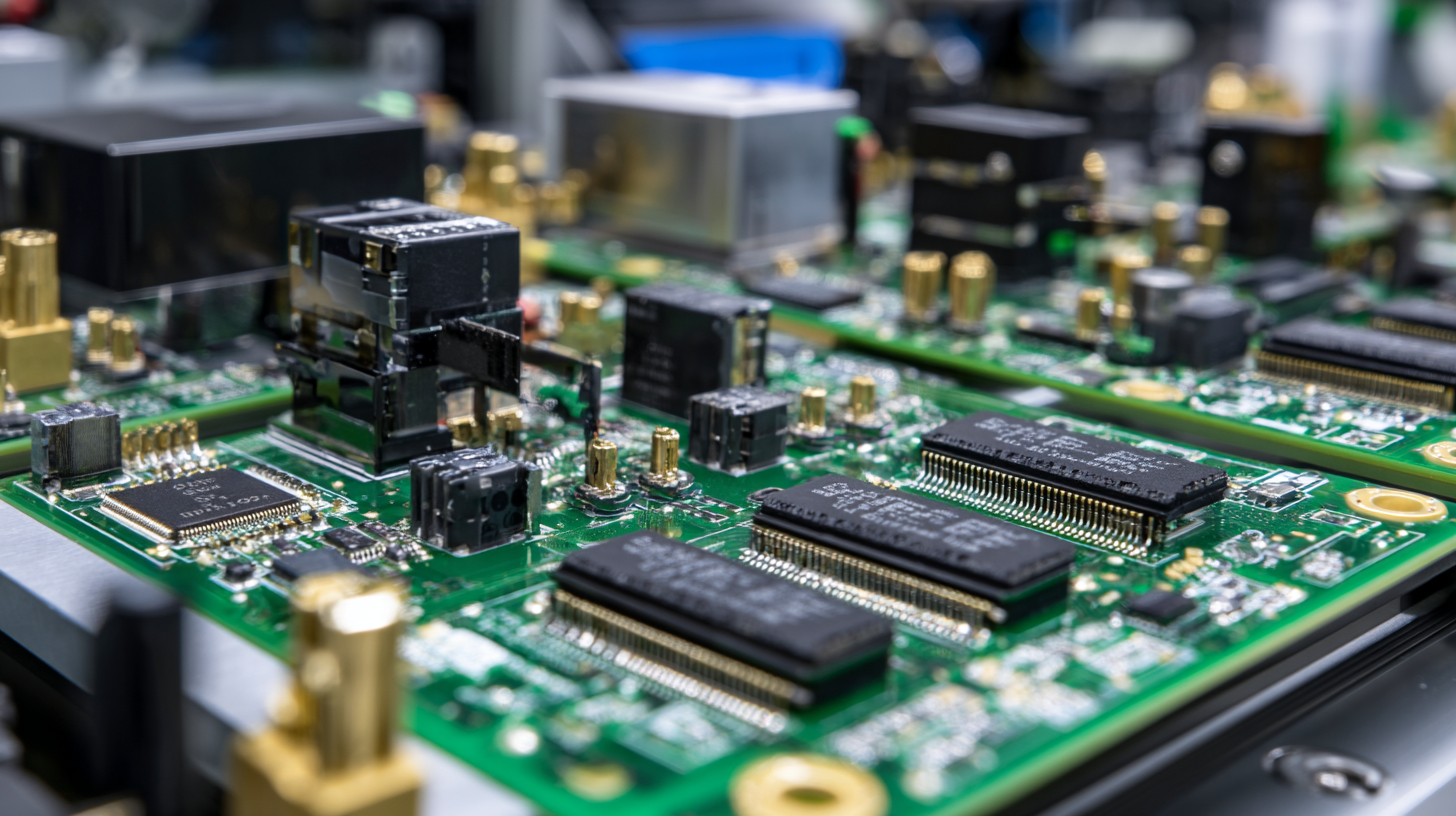

In the rapidly evolving semiconductor industry, advanced wire bonding techniques play a crucial role in enhancing both efficiency and longevity of semiconductor devices. Wire bonding is the process of connecting the semiconductor chip to its package or substrate, and its effectiveness significantly impacts device performance. By utilizing the best Kns wire bonder, manufacturers can achieve superior bond quality and reliability. These advanced machines not only provide precise control over bond parameters but also enable the use of innovative materials that enhance thermal and electrical conductivity.

Moreover, the implementation of sophisticated techniques in wire bonding, such as thermocompression and ultrasonic bonding, contributes to improved performance metrics. These techniques minimize the risk of defects while maximizing interconnection strength, which is essential for high-performance applications. As semiconductor devices become smaller and more complex, ensuring robust connections becomes paramount. By adopting cutting-edge wire bonding technologies, companies can not only boost the operational efficiency of their products but also extend their lifespan, leading to lower failure rates and increased customer satisfaction.

| Bonding Technique | Efficiency Improvement (%) | Impact on Longevity (Years) | Typical Application |

|---|---|---|---|

| Gold Wire Bonding | 15 | 10 | High-frequency RF devices |

| Aluminum Wire Bonding | 10 | 8 | Cost-sensitive applications |

| Copper Wire Bonding | 20 | 12 | High-performance computing |

| Ultrasonic Bonding | 18 | 9 | Power modules |

| Laser Bonding | 22 | 15 | Aerospace components |

The semiconductor industry is witnessing a remarkable transformation with the projected growth of wire bonding equipment. According to a report by MarketsandMarkets, the global market for wire bonding technology is anticipated to reach approximately $4.5 billion by 2025, growing at a CAGR of 6.2% from 2020. This surge is primarily driven by the increasing demand for advanced packaging solutions and the growing complexity of semiconductor devices, which necessitate more efficient and reliable wire bonding methods.

As manufacturers strive for higher performance and miniaturization of semiconductor components, the need for state-of-the-art wire bonders becomes more critical. Companies are investing in innovative technologies, including automated wire bonding systems, to enhance productivity and reduce operational costs. The latest data from SEMI indicates that the adoption of wire bonders in emerging markets, particularly in Asia-Pacific, is expected to propel the industry forward as semiconductor fabs look to upgrade their production capabilities. This trend reflects a broader movement towards integrated solutions that bolster efficiency in semiconductor manufacturing.

In the semiconductor industry, thermal management plays a crucial role in enhancing the performance of electronic devices. Recent advancements in Kns wire bonders have significantly improved thermal dissipation, ensuring that components operate efficiently even under demanding conditions. According to a report by Research and Markets, the global semiconductor market is projected to reach $1 trillion by 2030, primarily driven by innovations in manufacturing and assembly processes. Kns wire bonders have adapted to this demand by integrating advanced thermal management techniques, which help in minimizing thermal resistance and improving reliability.

Tip: When selecting a Kns wire bonder, consider models with integrated thermal measurement capabilities to better monitor and manage heat during the bonding process. This can lead to higher yield rates and reduced failures in the final products.

Moreover, the latest Kns wire bonders feature upgraded materials and design structures that enhance heat dissipation. A study published in the Journal of Semiconductor Technology and Science indicates that by utilizing high-conductivity materials, manufacturers can reduce device temperature by up to 25%, which directly correlates with increased performance and lifespan of semiconductor devices. This technological leap is vital as the industry moves towards miniaturization and higher power densities.

Tip: Stay updated on the latest Kns wire bonder features and consider investing in tools that allow for real-time thermal analysis, enabling timely adjustments during the production process to ensure optimal performance.

This chart illustrates the improvement in semiconductor performance metrics following enhancements in Kns wire bonders over the past five years. The data reflects advancements in thermal management and overall efficiency.

In the fast-paced world of semiconductor manufacturing, companies are continually seeking ways to improve efficiency and performance. Case studies illustrate how leading firms have successfully implemented advanced wire bonding technologies, resulting in significant enhancements in operational output. For instance, Firm A adopted a next-generation Kns wire bonder, which optimized their production line by reducing cycle times and increasing yield rates. This transition not only improved the reliability of their semiconductor devices but also lowered material costs.

Similarly, Firm B's integration of a state-of-the-art wire bonding solution led to a remarkable boost in production efficiency. By leveraging automated processes and real-time monitoring capabilities, they were able to minimize defects and streamline workflows. The results were evident in their quarterly performance metrics, showcasing a substantial decrease in rework and an increase in customer satisfaction. These case studies exemplify the remarkable benefits that can be achieved through the adoption of advanced wire bonding technologies, solidifying their importance in driving semiconductor innovation.