In the rapidly evolving landscape of modern manufacturing, the integration of advanced technologies and equipment is paramount for maintaining competitive edge and ensuring product quality. The Westbond Wire Bonder stands out as a crucial tool in this paradigm, particularly in sectors such as electronics, where the global market is projected to reach USD 1.9 trillion by 2025, according to a report by Market Research Future. This impressive growth is driven by the increasing demand for reliable interconnect solutions that are both efficient and durable. By employing Westbond Wire Bonders, manufacturers can benefit from high precision and enhanced bonding capabilities, leading to significant reductions in production time and costs. As the emphasis on "Made in China" continues to dominate global supply chains, the adoption of premium wire bonding technology, such as that offered by Westbond, is essential for companies aspiring to deliver quality products on a worldwide scale.

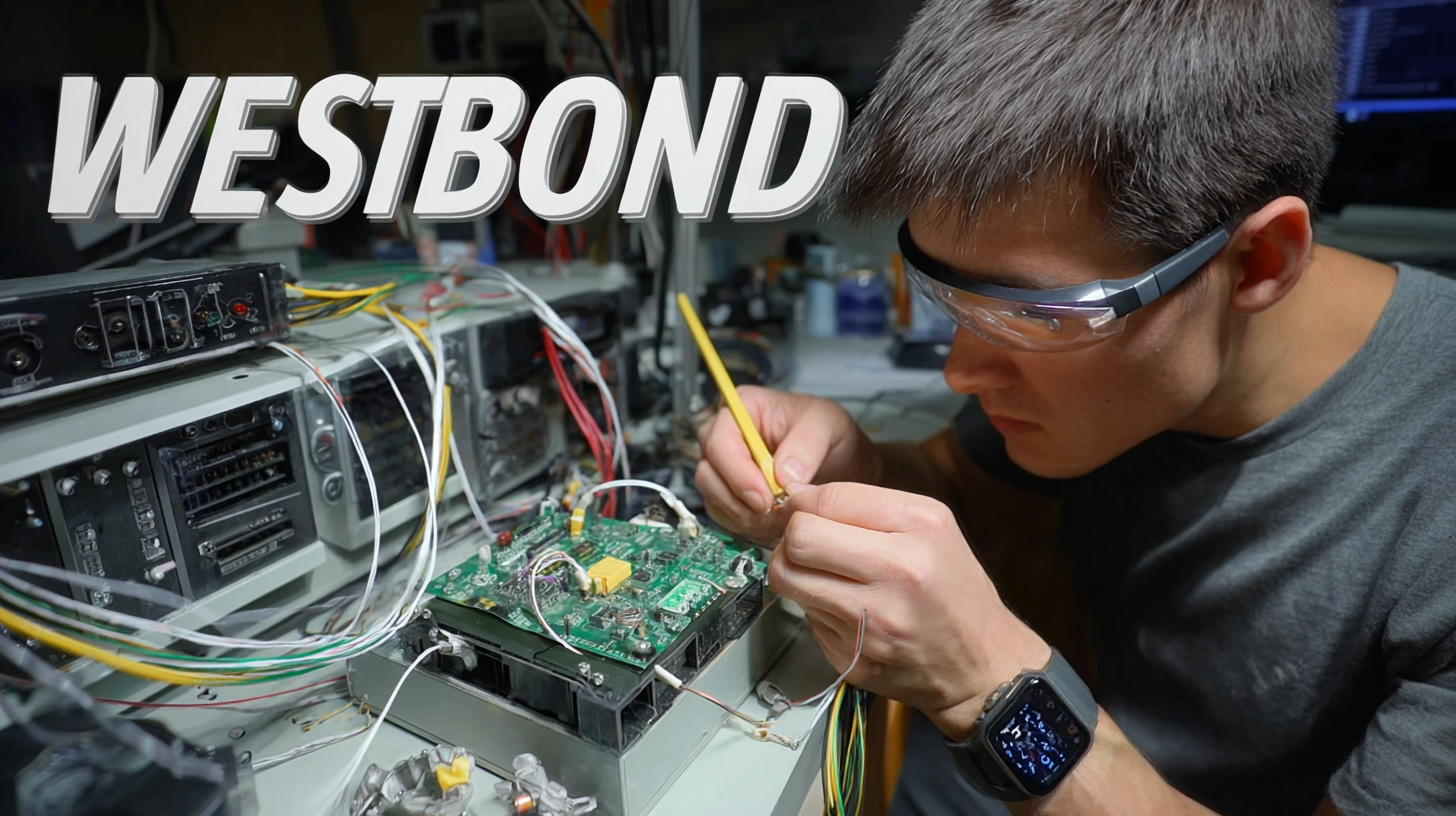

In today's fast-paced manufacturing landscape, precision is paramount, and the Westbond wire bonder stands out as a game-changer in wire bonding techniques. Enhanced precision not only ensures robust electrical connections but also optimizes the overall performance of electronic devices.

The Westbond wire bonder employs advanced technologies that minimize variances in wire placement, leading to improved reliability and fewer defects during the production process. This level of accuracy is critical, especially in industries where the smallest error can lead to significant failures or inefficiencies.

The Westbond wire bonder employs advanced technologies that minimize variances in wire placement, leading to improved reliability and fewer defects during the production process. This level of accuracy is critical, especially in industries where the smallest error can lead to significant failures or inefficiencies.

Moreover, the precision offered by the best Westbond wire bonders contributes to increased yield rates. Manufacturers can achieve tighter tolerances, meaning that more products meet quality standards during the initial production phase. This efficiency not only reduces waste but also accelerates time-to-market for new products. As industries continue to evolve, leveraging such advanced wire bonding techniques becomes essential for companies looking to maintain a competitive edge, ensuring they meet the high performance and quality expectations of their customers.

The modern manufacturing landscape is increasingly reliant on advanced technologies that enhance both production efficiency and quality. One of the standout innovations in this realm is the Westbond Wire Bonder. By utilizing state-of-the-art bonding techniques, this device significantly improves the quality of wire connections, ensuring a more robust electrical structure. As the demand for precision in semiconductor manufacturing rises, the Westbond Wire Bonder has become essential in delivering high-quality, defect-free bonds that meet industry standards.

Recent advancements in wire bonding detection solutions emphasize the importance of precise testing in quality assurance. The ability to identify subtle defects, such as wire sagging or near shorts, underscores the necessity of integrating efficient testing methodologies like advanced capacitance measurement. By implementing these solutions alongside the Westbond Wire Bonder, manufacturers can enhance their production processes, ensuring a thorough evaluation of bonding integrity and reducing the likelihood of production faults. This dual approach not only streamlines operations but also reinforces product reliability in a competitive market.

In modern manufacturing, leveraging advanced wire bonding solutions like the Westbond Wire Bonder significantly contributes to cost savings and operational efficiency. According to a 2021 report by Semiconductor Engineering, manufacturers incorporating optimized wire bonding techniques can reduce material waste by up to 20%. This not only lowers production costs but also enhances sustainability efforts, allowing businesses to minimize their environmental footprint while maintaining profitability.

Moreover, advanced wire bonding systems can expedite production times by automating processes that were once labor-intensive. The 2022 Manufacturing Technology Report highlights that companies utilizing automated bonding solutions have experienced a reduction in cycle times by up to 30%, leading to an overall increase in throughput. By streamlining these processes, manufacturers can meet market demands more efficiently, ultimately boosting their competitive edge. Investing in the best wire bonding technology not only enhances product reliability but also translates directly to significant economic benefits, making it a strategic choice in today's fast-paced manufacturing landscape.

In the ever-evolving landscape of modern manufacturing, Westbond technology stands out as a pivotal force in achieving industry standards. With its precision and reliability, the best Westbond wire bonder ensures that manufacturers can produce high-quality products consistently. This technology not only accelerates production processes but also improves interconnect reliability, which is crucial in industries such as electronics and automotive. By utilizing advanced features like programmable bonding parameters, manufacturers can fine-tune their processes to meet stringent quality controls and standards.

**Tip:** When considering a wire bonder, assess its compatibility with your existing production equipment. A seamless integration will help enhance efficiency and minimize downtime.

Moreover, Westbond technology addresses the growing demand for sustainability in manufacturing. It offers solutions that reduce material waste and energy consumption, aligning with corporate responsibility goals. As manufacturers strive to meet regulatory requirements and consumer expectations, investing in technology that adheres to these standards is essential for long-term success.

**Tip:** Regularly update your manufacturing protocols to align with the latest advancements in Westbond technology. This ongoing commitment can ensure compliance with evolving industry standards and contribute to a more sustainable operation.

| Feature | Description | Benefits | Impact on Industry Standards |

|---|---|---|---|

| High Precision | Advanced alignment systems ensure accurate bonding. | Reduces errors and improves product reliability. | Helps meet tight tolerances in electronic manufacturing. |

| Enhanced Speed | Operates at higher speeds compared to traditional bonders. | Increases output and reduces production time. | Facilitates just-in-time manufacturing practices. |

| Versatility | Supports various wire and bond types. | Flexible production for different products. | Aligns with diverse market demands and industries. |

| User-Friendly Interface | Intuitive controls and touchscreen operations. | Reduces training time and enhances operational efficiency. | Improves overall workforce productivity. |

| Sustainability Features | Energy-efficient designs and materials. | Lowers operational costs and promotes eco-friendliness. | Helps companies adhere to environmental regulations. |

In modern manufacturing, the implementation of advanced technologies is paramount for achieving efficiency and precision. Several factories have reported significant improvements after integrating Westbond Wire Bonders into their production lines. For instance, a case study from a leading electronics manufacturer demonstrated that after switching to Westbond wire bonding systems, they achieved a 30% reduction in cycle time and a 25% increase in overall productivity. This highlights the effectiveness of these machines in enhancing throughput while maintaining high-quality standards.

Another compelling example comes from a semiconductor facility that faced challenges with yield rates and operator errors. By adopting the Westbond Wire Bonder, they experienced a notable improvement in first-pass yields, jumping from 85% to over 95% within just three months of implementation. This data aligns with industry reports indicating that the use of precision wire bonding equipment can lead to yield enhancements of up to 15%. The combination of increased efficiency and improved yield not only maximizes profitability but also positions manufacturers to better meet the demands of an ever-evolving market.