In the rapidly evolving landscape of automation, the significance of effective pick up and place techniques cannot be overstated. As industries strive to enhance efficiency and productivity, mastering the art of "Die Pick Up And Place" has become paramount. This strategic approach not only streamlines operations but also reduces the margin for error, thereby fostering greater accuracy in manufacturing and distribution processes.

The year 2025 promises to usher in a new era of technological advancements that will redefine how businesses implement pick up and place automation techniques. Organizations are increasingly turning to innovative solutions that integrate sophisticated robotics and artificial intelligence to fulfill their operational demands. Understanding these emerging strategies is crucial for businesses aiming to thrive in a competitive market while ensuring sustainability and scalability.

In this guide, we will explore the top strategies for effective pick up and place automation techniques, focusing on the latest trends and technologies set to transform the industry. By delving into these strategies, companies can not only enhance their operational workflows but also achieve significant cost savings and improved service delivery. The future of automation is bright, and mastering "Die Pick Up And Place" techniques will be key to unlocking its full potential.

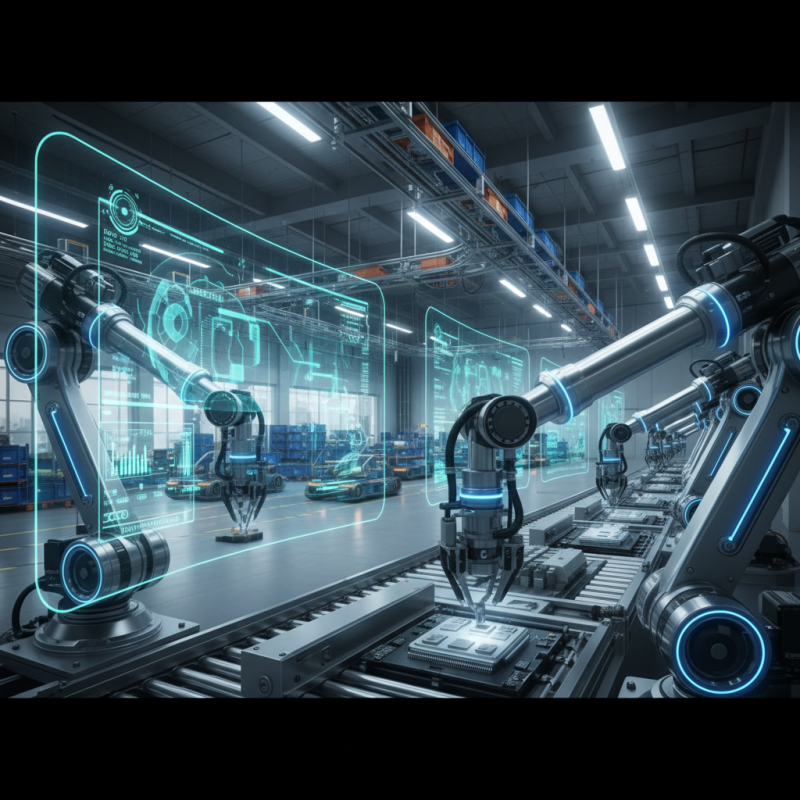

As we move into 2025, the landscape of robotic pick up and place automation is becoming increasingly sophisticated and essential for industries seeking efficiency and accuracy in their operations. According to a recent report by the International Federation of Robotics, the global market for robotics is projected to reach over $83 billion by 2025, underscoring the growing need for advanced automation solutions. To successfully implement these technologies, companies must focus on key strategies that enhance both operational performance and ROI.

One of the most effective strategies is to conduct a thorough assessment of existing processes to identify areas where automation can significantly elevate performance. This involves mapping out workflows and pinpointing bottlenecks that automation could alleviate. For instance, integrating machine learning algorithms can help robots adapt to various tasks, improving their efficiency over time. Furthermore, utilizing simulation software during the planning phase allows businesses to visualize the capabilities and requirements of their automation setup before actual deployment.

**Tip:** Ensure that training programs are in place for staff to adapt to new automation technologies. Engaging employees not only eases the transition but also fosters a culture of innovation. Another critical aspect is maintaining regular updates and support for robotic systems to keep them functioning at optimal levels and to quickly address any issues that may arise.

Ultimately, the future of robotic pick up and place automation lies in continuous improvement and adaptability. By prioritizing these strategies and maintaining a commitment to technology enhancement, organizations can ensure they remain competitive in the rapidly evolving market of 2025 and beyond.

| Strategy | Description | Key Benefits | Expected Impact (2025) |

|---|---|---|---|

| AI-Driven Vision Systems | Utilizing advanced algorithms to enhance object recognition and sorting capabilities. | Increased accuracy, reduced error rates. | Higher throughput and efficiency in logistics. |

| Flexible Robotic Arms | Implementing adaptable arms that can handle various product shapes and sizes. | Versatility in operations, reduced downtime for reconfiguration. | Improved handling of diverse inventory without additional costs. |

| Collaborative Robots (Cobots) | Robots designed to work alongside human workers safely. | Enhanced productivity, improved worker safety. | Higher job satisfaction and operational efficiency. |

| Predictive Analytics | Using data analytics to forecast inventory needs and optimize flow. | Reduced waste, improved inventory management. | Streamlined supply chain processes and cost savings. |

| Real-Time Monitoring Systems | Integrating IoT devices to monitor operational performance in real-time. | Immediate troubleshooting, increased reliability. | Enhanced overall equipment effectiveness (OEE). |

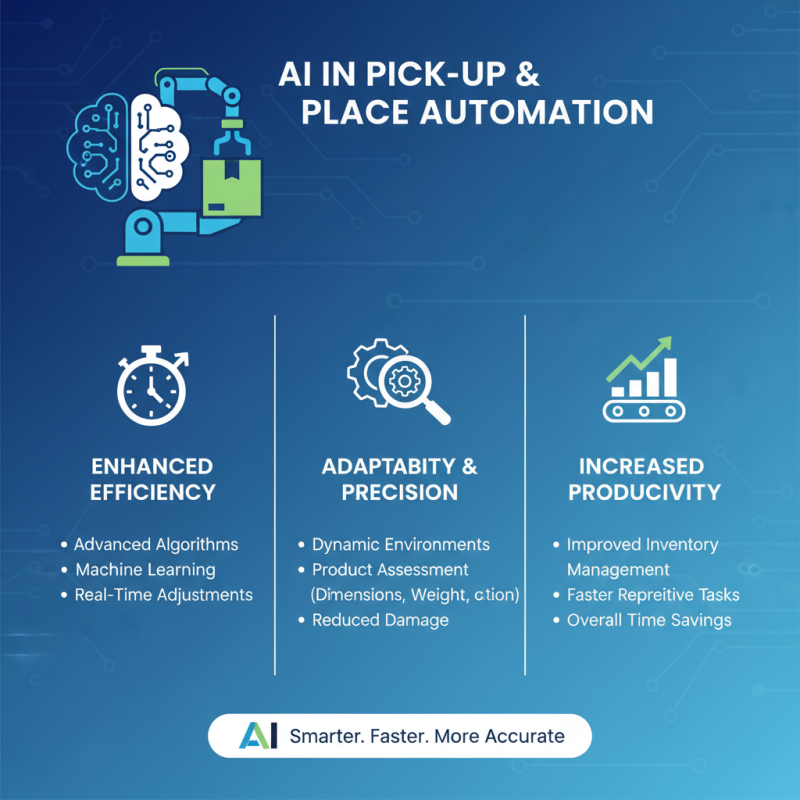

The integration of artificial intelligence (AI) into pick up and place automation systems has significantly enhanced operational efficiency across various industries. By employing advanced algorithms and machine learning techniques, AI empowers robotic systems to adapt to dynamic environments, making real-time adjustments that enhance precision and speed. This adaptability allows for improvements in inventory management and reduces the time spent on repetitive tasks, thereby increasing overall productivity. For instance, AI-driven systems can intelligently assess product dimensions, weight, and orientation, leading to more effective handling and reduced damage during transport.

Moreover, the implementation of AI in automation not only optimizes physical processes but also streamlines data collection and analysis. As these systems gather vast amounts of operational data, AI algorithms can analyze performance metrics and predict maintenance needs, preventing costly downtimes. This data-driven approach enables organizations to refine their workflow continuously and respond promptly to fluctuating demands. Ultimately, leveraging AI in pick up and place automation not only enhances efficiency but also provides a strategic edge in an increasingly competitive market, as businesses are better equipped to meet customer expectations and adapt to changing conditions.

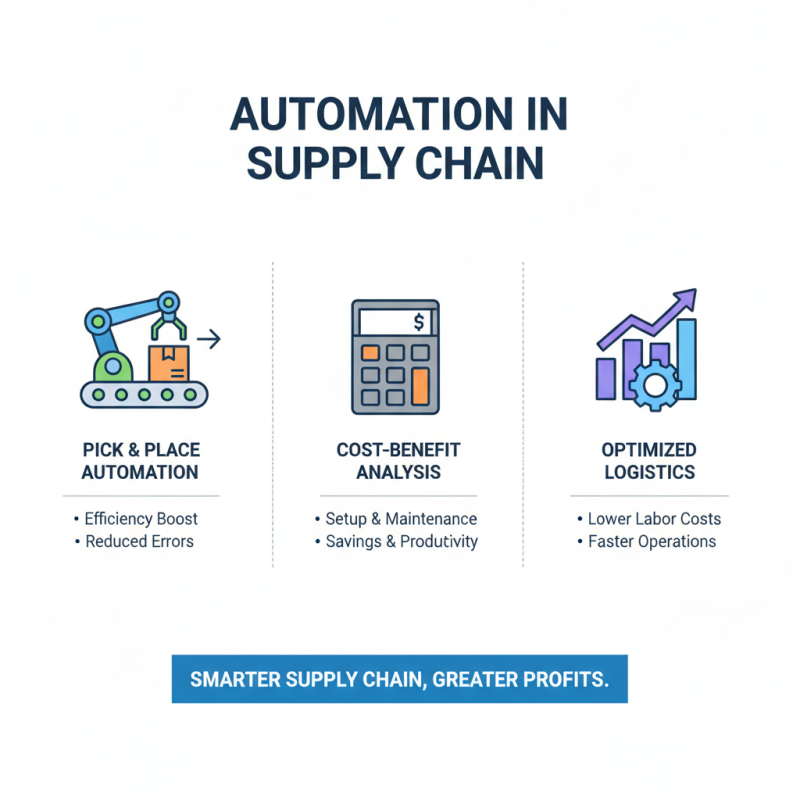

The integration of automation techniques in supply chain management presents a compelling opportunity for organizations to enhance operational efficiency. By employing pick-up and place automation, businesses can streamline their logistics processes, minimize labor costs, and reduce human error. However, a thorough cost-benefit analysis is essential to ascertain the financial viability of such technological investments. This analysis typically includes examining initial setup costs, ongoing maintenance expenses, and potential savings from increased productivity and reduced operational delays.

Furthermore, the economic impact of automation techniques can be profound. Companies often find that the upfront investment in automated systems is quickly offset by significant reductions in labor costs and improved accuracy in order fulfillment. This translates to better customer satisfaction and, ultimately, higher profits. Evaluating these factors allows businesses to make informed decisions, ensuring that they not only enhance their efficiency but also align with their broader strategic goals while optimizing their return on investment in automation.

The integration of machine learning (ML) into pick and place automation techniques is revolutionizing the manufacturing landscape. According to a report by Research and Markets, the global market for machine learning in manufacturing is projected to reach $15.72 billion by 2027, reflecting a compound annual growth rate (CAGR) of 42%. This rapid growth highlights the increasing reliance on data-driven technologies to enhance operational efficiency. By incorporating advanced algorithms and real-time data analysis, companies can optimize their pick and place automation processes to achieve remarkable precision, reducing the margin for error.

Machine learning enables systems to learn from vast datasets, continuously improving their performance. This ability is especially crucial in environments where precision is paramount, such as in semiconductor manufacturing or pharmaceutical packaging. A study published in the Journal of Manufacturing Science and Engineering found that implementing machine learning-driven automation can improve picking accuracy by up to 30%. Furthermore, the predictive analytics capabilities of ML can anticipate system failures and maintenance needs, thereby reducing downtime and ensuring seamless workflow. As industries seek to adapt to the demands of rapid production cycles and customized solutions, the integration of machine learning in automation processes will undoubtedly lead the way forward.

The field of robotics is rapidly evolving, and by 2025, we can expect significant advancements in pick-up and place automation techniques. One of the most notable trends is the integration of artificial intelligence and machine learning algorithms into robotic systems. These technologies enable robots to learn from their environments, improving their handling of a variety of objects with different shapes, sizes, and weights. This adaptive capability can substantially enhance the efficiency and accuracy of industrial automation processes, allowing for more versatile applications across diverse sectors.

Moreover, advancements in sensor technology will play a crucial role in the future of pick-up and place robotics. Enhanced sensors will enable robots to better perceive their surroundings, making real-time adjustments to handle dynamic environments. This capability will be crucial for applications in warehousing, manufacturing, and even healthcare. As robots become more adept at navigating complex spaces and interacting safely with human workers, we can anticipate a surge in their deployment for collaborative tasks, leading to more streamlined operations and heightened productivity in various industries.