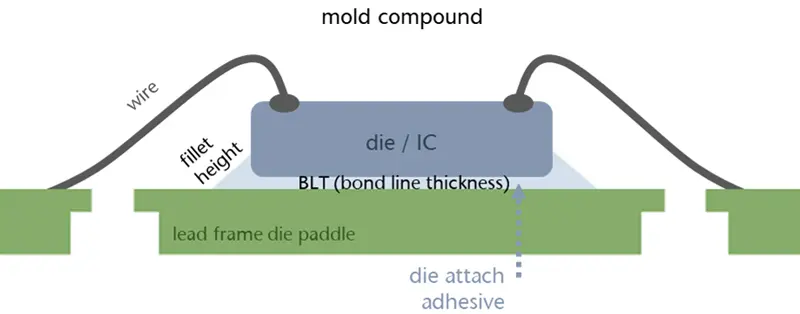

The process of die bonding or chip bonding involves attaching components to a PCB, wafer, or base plate of an application. Initially, adhesive or epoxy is administered to the preferred spot on the application, which can be accomplished using a dispenser or stamping tool. Subsequently, the component, known as a "die" or microchip, is selected using vacuum and positioned on the designated adhesive area. The application of suitable downforce strength and duration guarantees a stable and consistent outcome. This entire process is commonly referred to as "pick & place" and generally occurs as the final step before wire bonding.

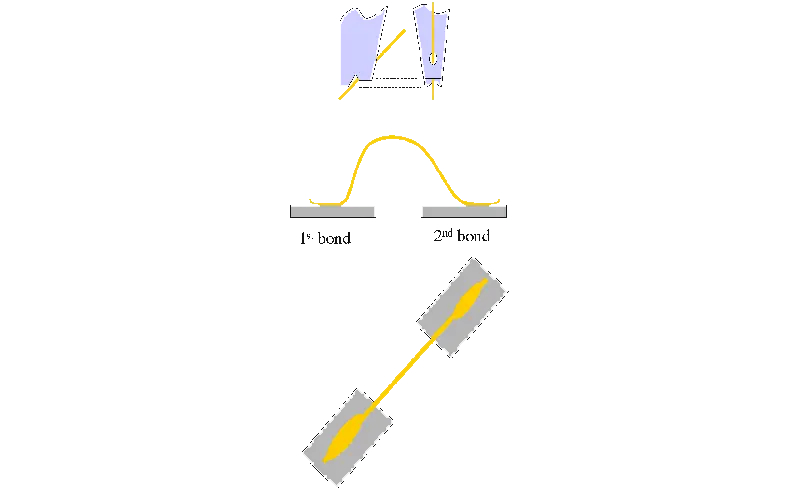

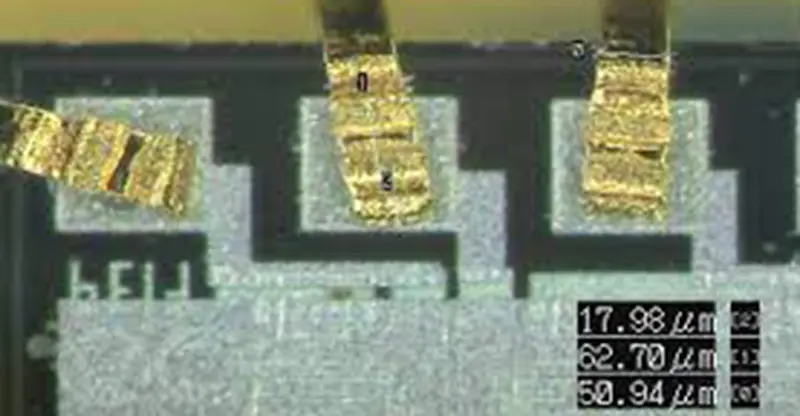

Ultrasonic Wedge Bonding or US Bonding is employed for bonding gold or aluminum wire. In power applications, copper wire is also suitable. There are three types of wire bonding: Thin wire bonding or wire bonding with wires ranging from 17 µm to 75 µm, heavy wire bonding with wires from 100 µm to 500 µm, and ribbon bonding with flat-band ribbons of various sizes.

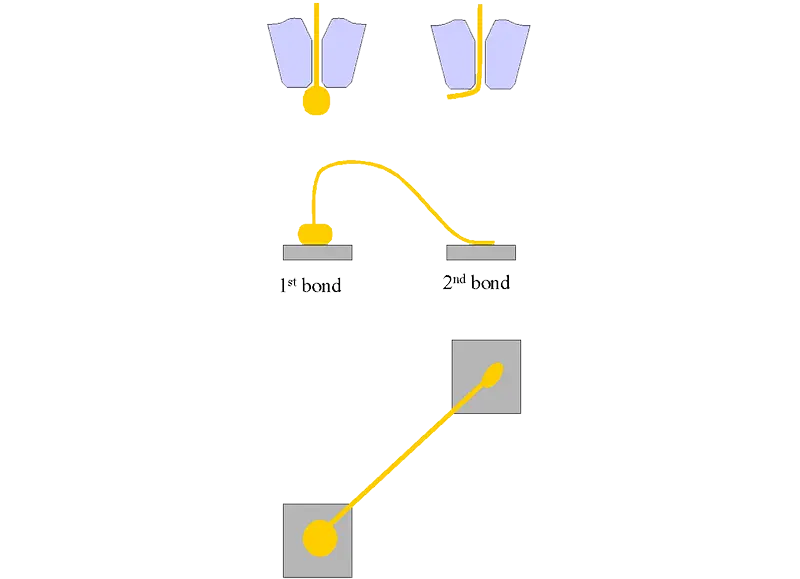

Thermosonic Ball Wedge Bonding, also known as TS Bonding, utilizes a mix of heat, pressure, and ultrasonic energy to form a connection between a gold, copper, or silver ball and the chip's surface. A gold, copper, or silver wire is passed through a capillary made of ultra-fine ceramics, on which a high-voltage electric charge is applied to the wire's tip. This process melts the wire into a ball, called "flame off." With the application of pressure (bond force) and ultrasonic energy, the capillary then connects this ball to the surface of the substrate. Following this, a loop is created, and a second bond is made in the form of a wedge bond, also known as a stitch bond.

Ribbon connections are characterized by their low impedance, which enables efficient transfer of electrical signals, and their significant ability to dissipate heat. These unique features make ribbons a popular choice for use in radio frequency (RF) technology, where the need for low impedance and effective heat dissipation is essential for optimal performance.